The Machine for Making Corrugated Roof Sheets A Modern Solution for Roofing Needs

In the world of construction and roofing, the demand for durable, lightweight, and cost-effective materials is continually on the rise. Among these materials, corrugated roof sheets have gained significant popularity due to their strength, versatility, and ease of installation. At the heart of the production of these essential building components lies an innovative machine specially designed for making corrugated roof sheets. This machine not only streamlines the manufacturing process but also enhances the quality and efficiency of the final products.

Understanding Corrugated Roof Sheets

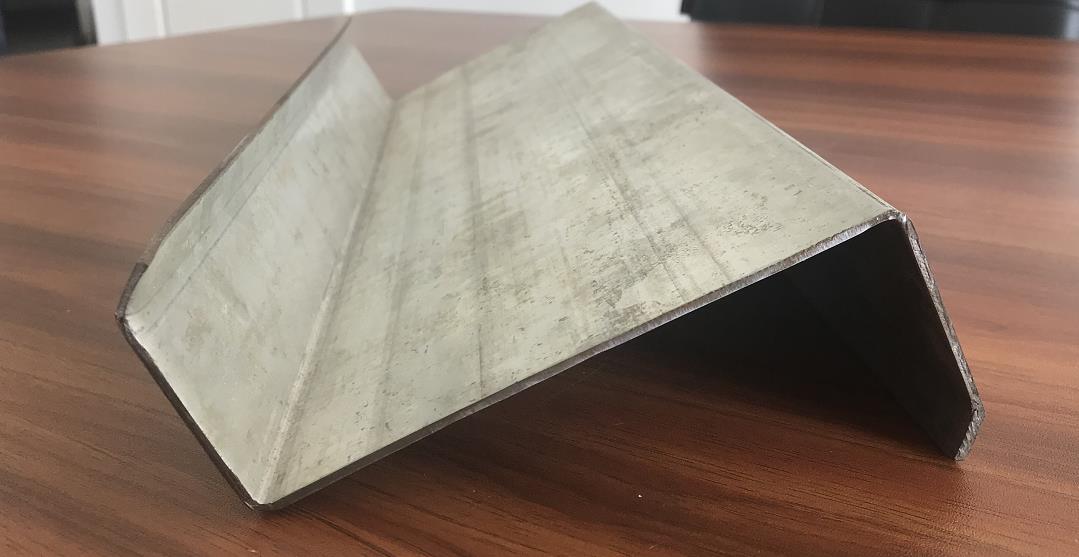

Before delving into the intricacies of the machine itself, it’s important to understand what corrugated roof sheets are and why they are widely used. Corrugated sheets are typically made from metal, plastic, or fiber and feature a series of parallel ridges and valleys. This design not only provides greater structural strength compared to flat sheets but also allows for efficient water drainage, making them ideal for various weather conditions.

These roof sheets are commonly used in residential, commercial, and industrial buildings. They’re widely favored for their lightweight nature, which significantly reduces the load on the building's structure, and their ease of installation, which can help to lower labor costs. Additionally, their durability ensures longevity, as they can withstand harsh weather conditions, including heavy rains, snow, and even hail.

The Machinery Behind Production

The machine for making corrugated roof sheets is a sophisticated piece of equipment that automates the production process. This machine typically includes several key components that work in tandem to create high-quality corrugated sheets.

1. Material Feeding System The process begins with a material feeding system, where metal coils or sheets are loaded into the machine. The feeding mechanism ensures that the material is fed consistently and smoothly into the production line.

2. Roll Forming System Once the material is fed into the machine, it passes through a series of rollers. These rollers are specifically shaped to impart the corrugated design onto the sheet. The roll forming system is critical as it determines the final profile of the sheet, including its height, width, and spacing of the corrugations.

3. Cutting Mechanism After the sheet has been formed, it needs to be cut to the desired length. The cutting mechanism, often synchronized with the roll forming process, ensures precision and repeatability, allowing for uniformity in the final products.

4. Support and Stacking System Once the corrugated sheets are cut, they move to a support and stacking system. This facilitates the orderly collection of finished sheets, making handling and transportation more efficient. Depending on the design of the machine, it may include features for automatically stacking or packaging the finished sheets.

Advantages of Using a Corrugated Roof Sheet Machine

The introduction of automated machines for making corrugated roof sheets brings numerous advantages. First and foremost, the efficiency of the production process is greatly enhanced, allowing manufacturers to increase output while maintaining quality standards. This is particularly beneficial in meeting high market demands while keeping production costs low.

Moreover, automated machines reduce labor costs since fewer workers are needed to manage the production process. Operators can monitor and control multiple machines, enhancing productivity without compromising safety and quality.

Another significant advantage is the ability to customize production. Many modern corrugated roof sheet machines are designed to handle various materials and can produce sheets of different sizes and profiles. This flexibility allows manufacturers to respond quickly to changing customer demands and preferences.

Conclusion

In conclusion, the machine for making corrugated roof sheets is an essential asset in the construction industry. By combining advanced technology with efficient manufacturing processes, it has revolutionized the production of a critical building material. As the demand for quality roofing solutions continues to grow, so too will the importance of these machines in providing innovative, durable, and cost-effective roofing options. With the ongoing advancements in machinery and materials, the future of corrugated roof sheets promises to be brighter than ever, paving the way for sustainable construction practices and enhanced building performance.