High Precision Straightening Machines Revolutionizing Leveling Processes

In the realm of industrial manufacturing and fabrication, the importance of precision can never be overstated. One critical aspect that contributes to the overall quality of finished products is the leveling of materials. Enter high precision straightening machines, which play a pivotal role in ensuring materials are not only straightened but also leveled to exact specifications. This technology is revolutionizing the way industries approach the leveling process, especially in sectors like metalworking, automotive, and aerospace.

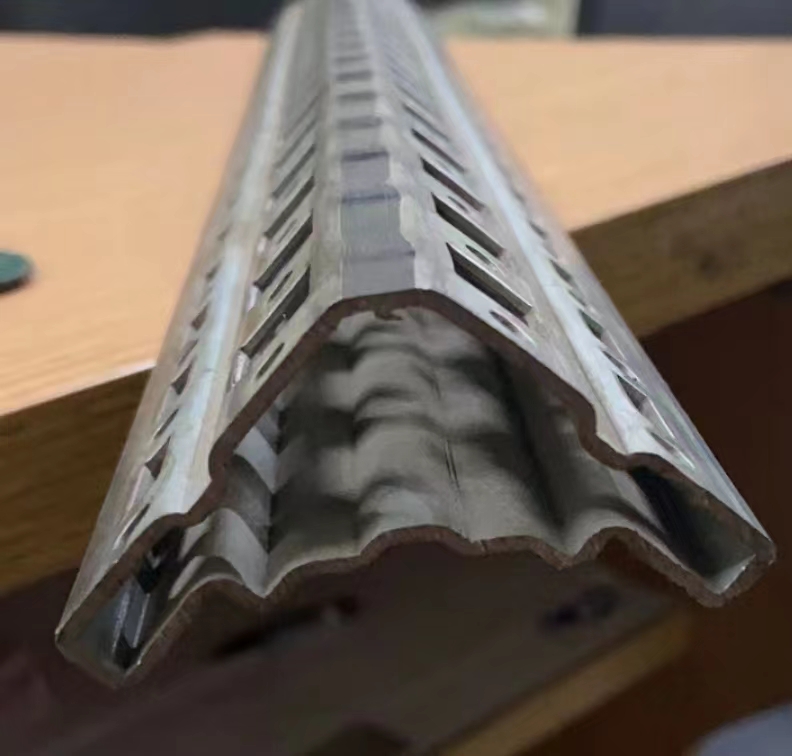

High precision straightening machines are designed to correct the deformations that occur during manufacturing processes. These deformations can arise from various factors, including bending, welding, or thermal treatments. The result is often materials that are not flat or have uneven surfaces, leading to challenges in subsequent processing steps, such as machining, welding, or assembly. By implementing high precision straightening, manufacturers can ensure greater accuracy and reduce the likelihood of defects in the final product.

The Mechanics Behind High Precision Straightening Machines

These machines utilize advanced technology to deliver precise straightening and leveling outcomes. Typically, they consist of rollers or a series of adjustable plates that apply controlled pressure to the material. As the material passes through the machine, the rollers exert force in a calculated manner to gradually bend the material back into its desired profile.

One of the key features of high precision straightening machines is their ability to be finely tuned. Operators can adjust parameters such as pressure, speed, and angle to accommodate various material types and thicknesses. This adaptability is crucial, as different metals or composites exhibit distinct behaviors under stress. Furthermore, many modern straightening machines are equipped with digital controls and feedback systems that monitor the straightening process in real-time, ensuring the highest level of accuracy.

Advantages of High Precision Straightening Machines

The benefits of employing high precision straightening machines are manifold. Firstly, they significantly improve the quality of the finished products. By ensuring that materials are perfectly straight and level, manufacturers can achieve tighter tolerances, which is critical in high-stakes industries such as aerospace and medical equipment.

Secondly, these machines enhance production efficiency. With the ability to straighten multiple pieces of material quickly and accurately, manufacturers can reduce the time spent on preparation and increase throughput. This efficiency not only translates to cost savings but also allows companies to meet stringent deadlines without compromising on quality.

Additionally, high precision straightening machines reduce material waste. When materials are not properly straightened or leveled, they may be deemed unusable, resulting in expensive waste. By investing in advanced straightening technology, manufacturers can minimize this loss and improve their overall environmental footprint.

Trends and Innovations

As technology continues to evolve, so do high precision straightening machines. The integration of automation and artificial intelligence (AI) is setting a new standard for precision and efficiency. Future advancements may include predictive maintenance systems that monitor machine performance and diagnose potential issues before they lead to breakdowns, further enhancing reliability.

Moreover, the push for sustainability in manufacturing processes is prompting the development of more energy-efficient machines that consume less power while maintaining performance. This trend aligns with global efforts to reduce carbon footprints and promote green manufacturing practices.

Conclusion

High precision straightening machines are essential tools in modern manufacturing, delivering significant improvements in the leveling process. As industries strive for quality, efficiency, and sustainability, these machines are becoming increasingly crucial. With ongoing innovations and a commitment to precision, the future of metal processing and fabrication looks exceptionally promising. Investing in high precision straightening technology not only elevates product quality but also secures a competitive edge in an ever-evolving market.