Understanding the Flex Beam Cold Bending Machine A Technological Marvel in Metal Working

The manufacturing industry is constantly evolving, and one of the standout innovations in recent years is the flex beam cold bending machine. This advanced piece of machinery plays a crucial role in the metalworking sector, particularly in bending metal beams with precision and efficiency. By examining its functionality, benefits, and applications, we can better understand why it's become an indispensable tool in modern fabrication.

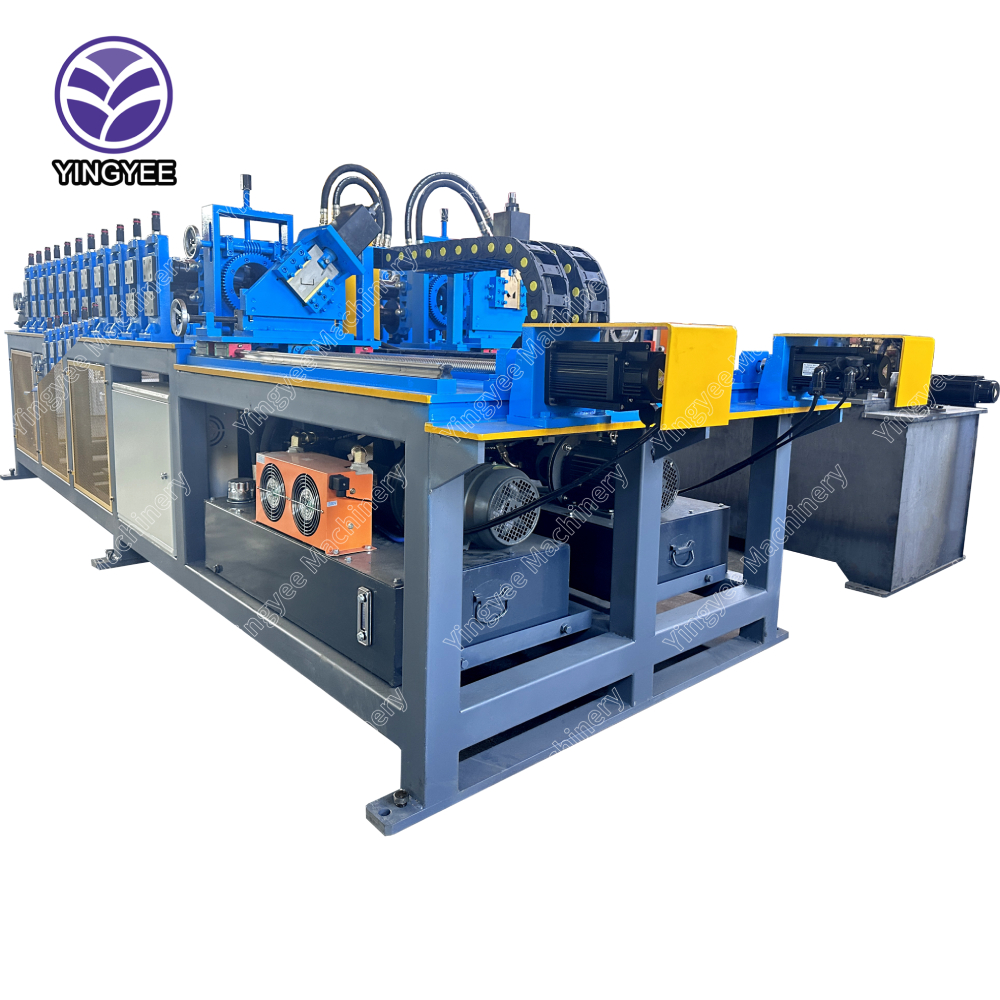

What is a Flex Beam Cold Bending Machine?

At its core, a flex beam cold bending machine is designed to bend metal beams without the need for heat. Traditional bending methods often involve heating the metal before shaping it, which can lead to structural weaknesses or alterations in the material properties. In contrast, cold bending maintains the integrity of the metal, resulting in a stronger and more durable product.

The machine operates using a series of rollers and dies, which apply controlled force to the metal beam. By gradually bending the material, the machine can achieve various angles and curvatures with remarkable accuracy. This flexibility makes it suitable for creating intricate designs and adhering to specific project requirements.

Key Advantages of Flex Beam Cold Bending Machines

1. Precision and Accuracy One of the primary advantages of cold bending is the precision it offers. The machine is equipped with advanced digital controls and sensors that ensure consistent measurements throughout the bending process. This precision is critical in industries where exact specifications are paramount, such as aerospace and automotive manufacturing.

2. Material Integrity Cold bending minimizes the risk of heat-induced damage to the metal. As the material is not exposed to high temperatures, there is a reduced chance of warping or weakening the metal, which can occur with traditional methods. This results in a product that maintains its original specifications and performance capabilities.

3. Increased Production Efficiency A flex beam cold bending machine significantly increases production rates compared to manual bending methods. With automated controls and high-speed operation, manufacturers can achieve more in less time, ultimately reducing labor costs and increasing output.

4. Versatility These machines can handle a variety of materials beyond just steel, including aluminum, brass, and other alloys. This versatility allows manufacturers to expand their range of products without the need for multiple machines, thus saving space and resources.

5. Eco-Friendly Operations Since the process does not involve heating the material, energy consumption is lower compared to traditional bending operations. This makes the flex beam cold bending machine not only cost-effective but also more environmentally friendly.

Applications in Various Industries

The applications of flex beam cold bending machines are vast and varied. In the automotive industry, they are used to create frames and structural components that must meet stringent safety standards. In construction, these machines produce beams and supports for buildings and infrastructure projects, ensuring that they can withstand environmental stresses and loads.

In the aerospace sector, where safety and precision are critical, manufacturers rely on cold bending machines to create parts that must adhere to rigorous specifications. The ability to produce complex geometries without compromising material integrity makes these machines invaluable.

Conclusion

In conclusion, the flex beam cold bending machine represents a significant advancement in the metalworking industry. Its ability to bend metal with precision while maintaining the material's integrity offers manufacturers a competitive edge in various sectors. As technology continues to evolve, the flex beam cold bending machine will likely see further advancements, enhancing its capabilities and applications. This innovation exemplifies the intersection of technology and craftsmanship, paving the way for a future where high-quality metal fabrication is both efficient and reliable.