The Changeable U Purlin Roll Forming Machine An Innovation in Steel Fabrication

In the ever-evolving landscape of construction and manufacturing, the demand for versatile and efficient machinery is paramount. One such technological innovation that has emerged to meet these needs is the changeable U purlin roll forming machine. This machine is not only essential for producing high-quality steel purlins but also offers flexibility in dimensions and designs, allowing manufacturers to cater to a diverse range of structural applications.

What are U Purlins?

U purlins are essential components in the construction industry, primarily serving as horizontal supports for roofing structures. The U-shaped profile offers strength and durability, making it an excellent choice for a variety of buildings, including warehouses, industrial facilities, and residential structures. Given their crucial role in structural integrity, the accurate and efficient production of U purlins is of utmost importance.

Advantages of Changeable U Purlin Roll Forming Machines

1. Versatility in Design One of the standout features of changeable U purlin roll forming machines is their ability to produce different sizes and shapes of purlins. Unlike fixed-form machines, changeable options allow manufacturers to quickly adjust settings and molds to create custom profiles. This versatility is invaluable for catering to specific customer requirements and adapting to various construction standards.

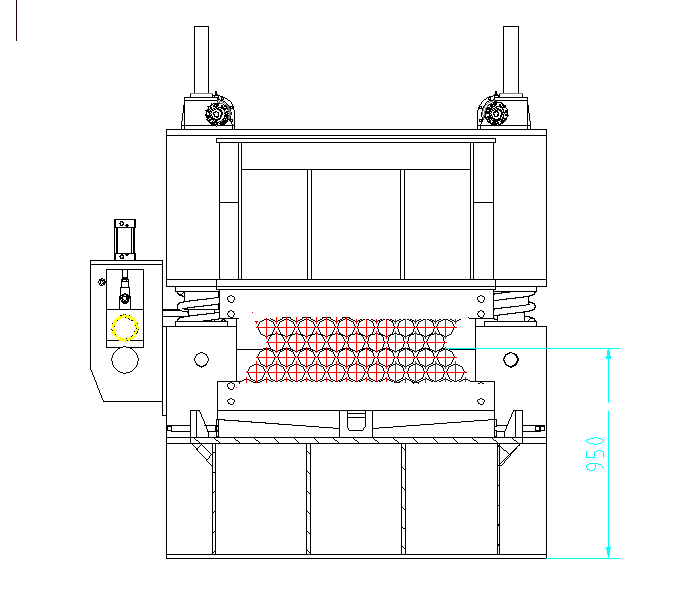

2. Enhanced Efficiency With advancements in automation technology, these machines are designed to operate at high speeds while maintaining precision. The process typically involves a series of rollers gradually shaping flat steel into the desired U purlin profile. Operators can set the machine to work continuously, significantly reducing production time and labor costs.

3. Cost-Effective Production The ability to change the dimensions of the purlins on the same machine eliminates the need for multiple specialized machines. This not only reduces capital investment but also minimizes floor space in factories. Furthermore, with reduced setup times, manufacturers can respond more quickly to market demands without incurring excessive costs.

4. High Precision and Quality Modern changeable U purlin roll forming machines incorporate advanced technology for automated control, ensuring that each profile produced meets stringent quality standards. The machines are equipped with sensors that monitor processes in real-time, enabling immediate adjustments to maintain uniformity and accuracy.

5. Robust Construction and Durability Given that U purlins must withstand various environmental stresses, the machines used for their production are built to last. Most changeable U purlin roll forming machines are constructed from high-quality materials and undergo rigorous testing to ensure they can handle ongoing operational demands without compromise.

Applications of U Purlins

The U purlin produced by these machines is utilized in various applications. They are commonly used in

- Roofing Systems Acting as support beams that hold roofing sheets, ensuring structural stability and weight distribution. - Structural Frameworks Providing essential support in both residential and commercial buildings. - Storage Solutions Forming the base structure for shelves in warehouses and storage facilities. - Pre-Engineered Buildings Serving as integral components in pre-engineered construction, allowing for quick assembly and reduced labor costs.

The Future of Roll Forming Technology

As construction trends lean increasingly towards customization and efficiency, the role of changeable U purlin roll forming machines becomes more vital. Manufacturers are investing in intelligent manufacturing systems that incorporate artificial intelligence and machine learning. These technologies can further enhance precision, predict maintenance needs, and optimize production workflows.

In conclusion, the changeable U purlin roll forming machine represents a significant leap forward in the production of structural components. Its versatility, efficiency, and ability to produce high-quality products align perfectly with the modern demands of the construction industry. As technology continues to advance, we can expect these machines to become even more integral to efficient and sustainable building practices, contributing to the future of construction worldwide.