Swing Shearing Machine Factory A Vital Pillar in Manufacturing Industry

In the rapidly evolving landscape of modern manufacturing, the efficiency and precision of tools play a crucial role in determining the productivity and quality of end products. Among these, the swing shearing machine stands out as a vital instrument, crucial for metal processing industries. Swing shearing machines are predominantly used for cutting sheet metal into desired sizes and shapes with high precision. This article discusses the significance of swing shearing machines, the factors influencing their manufacturing, and a look at a typical swing shearing machine factory.

Understanding Swing Shearing Machines

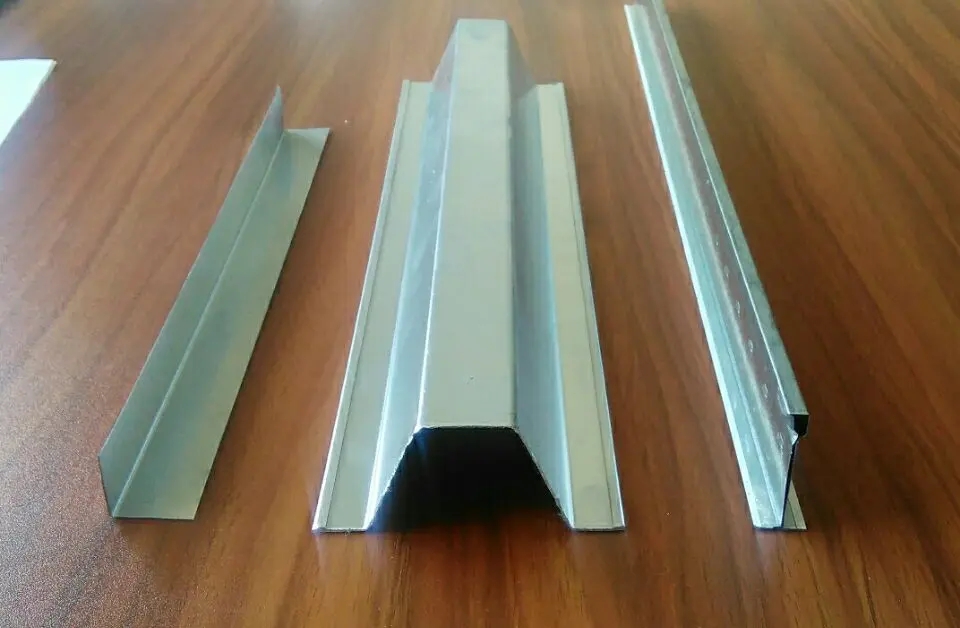

Swing shearing machines utilize a forging mechanism, where the blade pivots on a fixed point, delivering powerful shearing action as it descends. This design allows for more efficient energy transfer, minimizing wear and tear on the components, which ultimately enhances the machine's lifespan. They are particularly favored in industries that require substantial sheet metal manipulation, such as automotive, aerospace, and construction sectors.

The Role of a Swing Shearing Machine Factory

A swing shearing machine factory plays an indispensable role in the manufacturing ecosystem. These factories are specialized facilities where various models of swing shearing machines are produced, showcasing the latest technologies in manufacturing. Machines are designed and constructed to meet specific requirements and standards, ensuring that they cater to diverse industrial applications.

At a typical swing shearing machine factory, the production process begins with research and development, where engineers design machines that reflect the evolving needs of the market. Advanced prototypes are created, taking into consideration factors such as cutting capacity, material types, and automation levels. This phase is crucial as it sets the foundation for quality and reliability.

Once a prototype is approved, the next stage involves sourcing high-quality materials. This is a critical phase in the production process; materials used in the construction of swing shearing machines, such as high-grade steel for blades and robust metals for the body, greatly influence durability and performance. The factory's commitment to quality materials ensures that finished products can withstand rigorous industrial applications over a long period.

After material procurement, the manufacturing process commences. Skilled technicians and engineers work together, employing various fabrication techniques, including welding, machining, and assembly. Each machine must pass stringent quality control tests at multiple stages to ensure they meet both global standards and customer requirements. This meticulous attention to detail enhances the longevity and efficiency of the machines being produced.

Innovation and Future Prospects

As technology advances, swing shearing machine factories are also evolving. The integration of automation, artificial intelligence, and advanced control systems into the design and manufacturing processes is revolutionizing the industry. These innovations are aimed at enhancing operational efficiency, improving safety, and minimizing waste, making swing shearing machines more competitive in the global market.

Moreover, environmental considerations are playing an increasingly prominent role in factory operations. Many manufacturers are focusing on sustainable practices, such as utilizing eco-friendly materials and reducing energy consumption throughout the production cycle.

Conclusion

In summary, swing shearing machine factories are pivotal in shaping the future of manufacturing. By producing high-quality, efficient machines that meet the needs of various industries, these factories not only contribute to the economy but also drive technological advancements in manufacturing. As industries continue to evolve, the need for reliable and innovative swing shearing machines will remain, solidifying the significance of these factories in the global market.