The Versatility and Importance of Purlin Forming Machines

In the world of construction and manufacturing, efficiency and precision are paramount. Among the essential equipment in modern construction processes is the purlin forming machine. This specialized machinery plays a crucial role in fabricating purlins, which are structural components used to support roofs and walls in various types of structures, including warehouses, industrial buildings, and residential homes. Understanding the functionality, benefits, and applications of purlin forming machines can illuminate their significance in contemporary construction practices.

What is a Purlin Forming Machine?

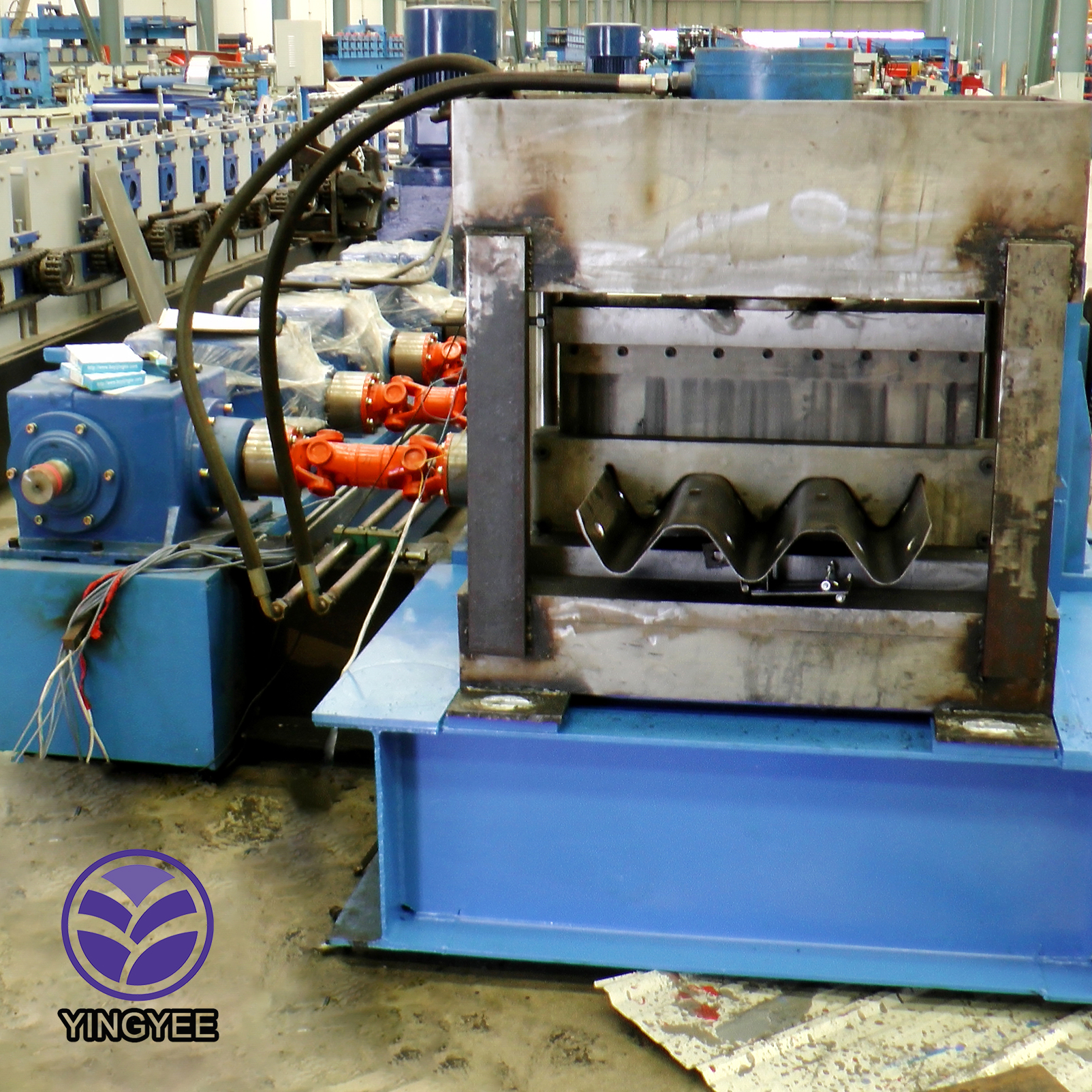

A purlin forming machine is designed to produce metal purlins from a coil of metal sheet. The process involves feeding a roll of steel, typically galvanized steel or aluminum, into the machine. The machine then mechanically shapes and cuts the metal into specific forms, producing purlins that meet predetermined specifications. These purlins can vary in size, shape, and thickness, allowing for customization based on the structural requirements of the project.

How Does a Purlin Forming Machine Work?

The operation of a purlin forming machine involves several stages

1. Material Loading Metal coils are loaded onto the machine's decoiler, which unwinds the steel coil for further processing. 2. Roll Forming As the steel coil moves through the machine, it passes through a series of rollers that gradually shape it into the desired purlin profile. The rollers are strategically positioned, allowing for precise bending without compromising the metal's integrity.

3. Cutting Once the purlin has reached the required length, a cutting mechanism ensures that each piece is accurately severed. This can be done using a shear blade, which provides a clean cut.

4. Formation After cutting, the purlins are often supported on an output table for further handling and packaging, ready to be transported to construction sites.

Benefits of Using Purlin Forming Machines

1. Efficiency Purlin forming machines streamline the production process, allowing manufacturers to produce large quantities of purlins in a fraction of the time it would take to cut and shape them manually.

2. Precision The automated nature of these machines ensures that every purlin produced meets exact specifications. This reduces waste and the likelihood of errors, which can be costly in construction projects.

3. Cost-Effective By shortening production times and minimizing waste, purlin forming machines can significantly reduce manufacturing costs, making them an attractive investment for construction companies.

4. Versatile Applications Purlins produced by these machines can be used in various applications beyond roofing, including supporting walls, creating frames for industrial buildings, and even in agricultural buildings.

5. Durability and Strength The high-quality steel often used in conjunction with purlin forming machines results in products that are not only lightweight but also robust, capable of withstanding various environmental conditions.

Applications of Purlin Forming Machines

Purlin forming machines are utilized across multiple sectors

- Commercial Construction Large commercial buildings, like shopping centers and office complexes, typically require purlins for structural support. These machines enable quick and efficient production to meet the demands of large-scale projects.

- Industrial Facilities Factories and production plants often use metal purlins in their construction for robust frameworks. Purlin forming machines facilitate the high-volume output needed for such facilities.

- Agricultural Structures Barns and greenhouses also benefit from purlins as they provide a reliable framework for roofs and walls, ensuring stability and durability.

- Residential Roofing With the rise of prefabricated homes, purlins are increasingly being used in residential construction, providing strong supports for various roofing designs.

Conclusion

The purlin forming machine is a pivotal tool in the modern construction landscape. By enhancing efficiency, precision, and cost-effectiveness, it has transformed how structural components are produced. As the demand for resilient and reliable building solutions continues to grow, the significance of purlin forming machines will undoubtedly increase, making them indispensable in both commercial and residential construction projects. Investing in advanced purlin forming technology is not merely an operational improvement; it is a step towards embracing the future of construction innovation.