The Importance and Functionality of Keel Roll Forming Machines

In the ever-evolving world of manufacturing and metalworking, efficiency and precision remain critical for businesses aiming to enhance productivity and maintain high-quality standards. Among the various processes used in metal shaping, keel roll forming has emerged as a vital technique, particularly in the construction and automotive industries. This article explores the significance and functionality of keel roll forming machines, their applications, and the advantages they offer.

Understanding Keel Roll Forming

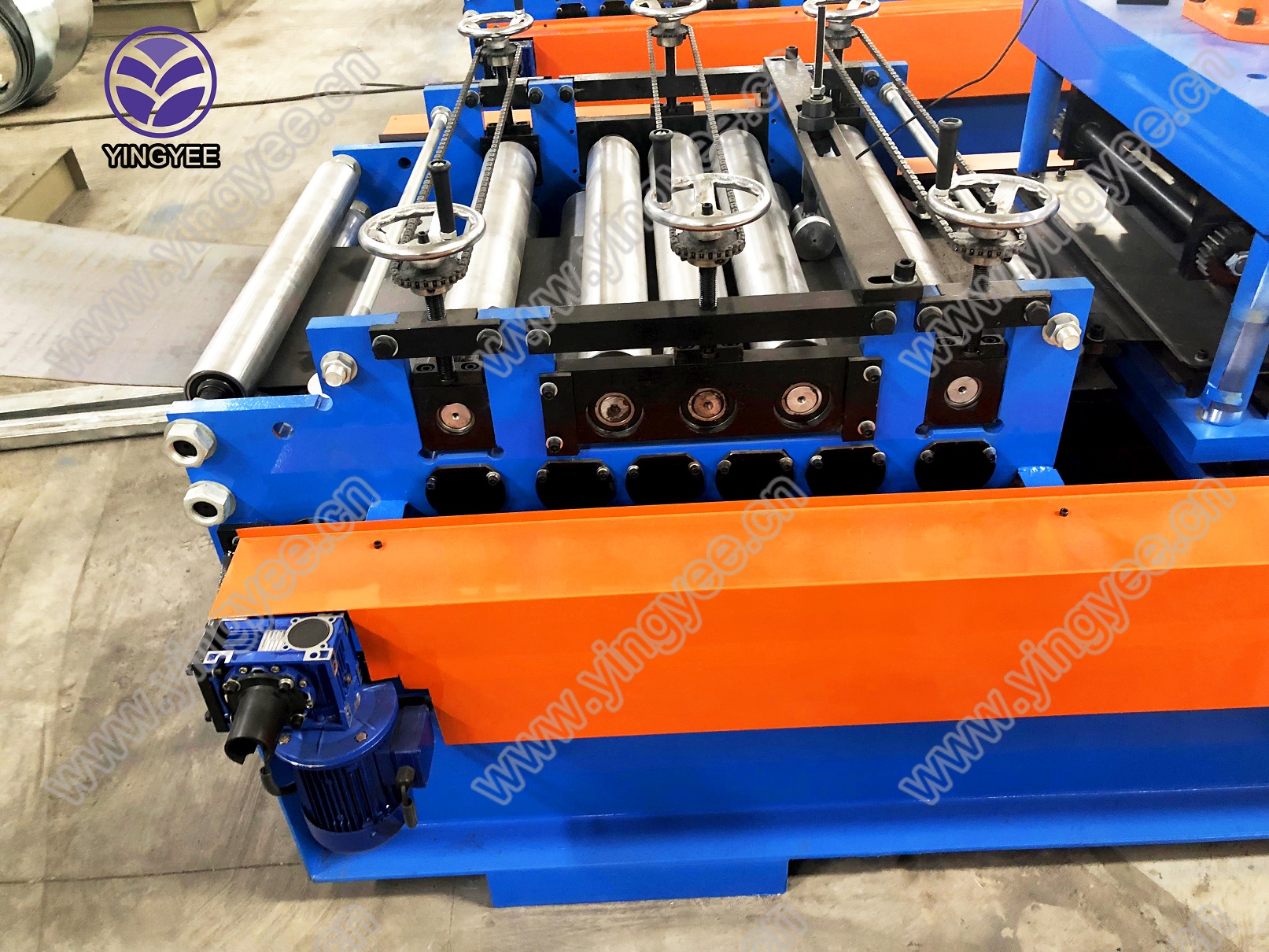

Keel roll forming is a continuous bending process where metal sheets are fed through a series of rollers to achieve desired shapes and profiles. The term keel is often associated with the structure of vessels and buildings, reinforcing the importance of these machines in creating essential structural components. The machines use a sequence of forming stations, each progressively influencing the sheet metal to create a final profile that can have various applications.

Applications of Keel Roll Forming Machines

Keel roll forming machines find extensive use in various sectors, including

1. Construction They are instrumental in producing structural components such as roof purlins, wall girts, and other critical framing elements that provide strength and support to buildings. 2. Automotive The automotive industry employs keel roll forming machines to create parts such as chassis rails, reinforcements, and various body components where strength-to-weight ratios are essential.

3. Shipbuilding In the shipbuilding sector, these machines craft keels and other necessary structural items integral to vessel stability and performance.

Advantages of Keel Roll Forming Machines

The use of keel roll forming machines offers several advantages that enhance productivity and efficiency

1. Precision and Consistency The automated nature of keel roll forming machines ensures high levels of accuracy in producing components. The consistent quality of the parts minimizes wastage and reduces errors, which is particularly crucial in industries where tolerances can be minimal.

2. High Production Efficiency Keel roll forming is a continuous process, allowing for the rapid production of components. This high throughput helps manufacturers meet tight deadlines and respond swiftly to market demands.

3. Material Versatility These machines can work with various materials, including steel, aluminum, and even certain plastics, making them adaptable to different industry needs.

4. Cost-Effectiveness While the initial investment in keel roll forming machinery may be significant, the long-term savings in labor costs, reduced material wastage, and high output justify this expense. Furthermore, the durability of the components produced can lead to lower maintenance costs over time.

5. Customizable Designs Manufacturers can easily modify the tooling in keel roll forming machines to create custom profiles suited to specific project requirements, giving businesses a competitive edge.

Conclusion

As industries continue to seek greater efficiencies and higher-quality output, keel roll forming machines serve as a cornerstone technology in metal fabrication. Their ability to produce strong, lightweight, and precisely shaped components makes them indispensable tools in sectors ranging from construction to automotive and beyond. Emphasizing automation and precision, keel roll forming machines not only contribute to lower production costs but also support the innovation and customization that modern manufacturing demands. For businesses looking to enhance their manufacturing capabilities, investing in advanced keel roll forming technology could be a pivotal step toward achieving long-term success in a competitive marketplace.