The Innovative IBR Making Machine Revolutionizing Building Materials Production

In recent years, the construction industry has seen significant advancements in technology, leading to more efficient and sustainable production methods. One of the most impactful innovations has been the development of the Interlocking Brick or IBR making machine. This machine streamlines the production of interlocking bricks, which have gained popularity due to their structural integrity, aesthetic appeal, and environmental benefits.

Understanding IBR

Interlocking bricks are specially designed bricks that fit together without the need for mortar, creating a strong and stable structure. They are made from a mixture of soil, cement, and water, which is compressed into various shapes and sizes. These bricks not only reduce the amount of cement needed in construction but also promote faster building times and cost efficiency. The IBR making machine is crucial in this process, allowing for the mass production of uniform bricks with minimal human labor.

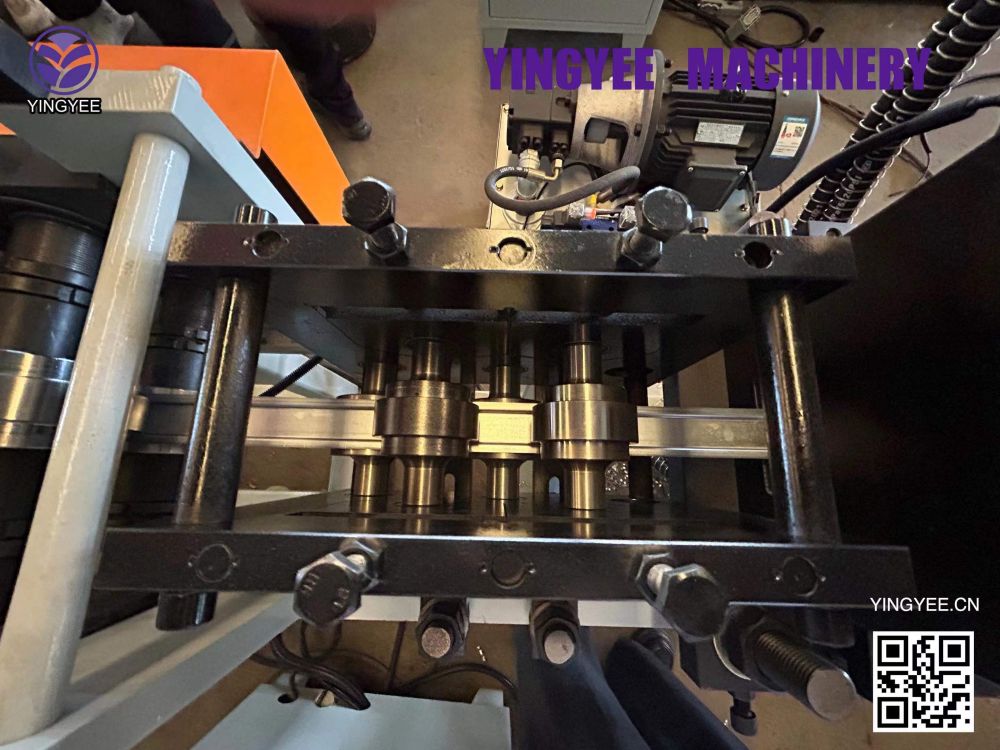

The Technology Behind IBR Making Machines

At the heart of the IBR making machine is a hydraulic press that compresses the raw material mixture to form bricks. The machine operates on the principle of high pressure, which ensures that the bricks have a high density and strength. Modern IBR machines also come with advanced features such as automatic feeding systems, programmable controls, and sensors that monitor the pressure and moisture levels during the manufacturing process. This level of automation not only increases productivity but also enhances the quality of the finished product.

Environmental Benefits

One of the most significant advantages of using an IBR making machine is its contribution to sustainability. Traditional brick-making processes often involve firing clay bricks at high temperatures, resulting in considerable energy consumption and carbon emissions. In contrast, interlocking bricks made with an IBR machine require less energy to produce and can be made from locally sourced materials. Furthermore, the use of these bricks can reduce the overall environmental impact of construction projects, making them a greener alternative.

Economic Advantages

Adopting IBR technology can lead to considerable cost savings for builders and developers. The use of interlocking bricks reduces the need for skilled labor, as they can be easily stacked without the expertise required for traditional brick-laying methods. This not only cuts down on labor costs but also accelerates construction timelines. As a result, developers can complete projects faster and at a lower cost, which can be particularly beneficial in competitive markets.

Applications in Construction

The versatility of interlocking bricks, produced using IBR making machines, makes them suitable for a wide range of applications. They can be used in the construction of residential buildings, commercial spaces, and even schools. Additionally, because these bricks don’t require mortar, they can also be employed in disaster relief situations where building speed is crucial. The interlocking design provides excellent seismic resistance, making them a valuable option in earthquake-prone regions.

Challenges and Future Prospects

Despite the numerous advantages of IBR making machines, there are some challenges that the industry faces. The initial investment for the machinery can be substantial, which may deter small builders or startup companies. Additionally, educating the workforce on the best practices for using and maintaining these machines is essential for maximizing their potential.

Looking ahead, the future of IBR making machines appears bright. As more construction companies prioritize sustainability and efficiency, the demand for interlocking bricks is likely to increase. Innovations in machine technology, such as improved automation and energy efficiency, will continue to drive the industry forward.

Conclusion

The IBR making machine stands at the forefront of modern construction technology, offering a sustainable and economical alternative to traditional brick-making methods. By enabling the production of high-quality interlocking bricks, these machines are not only revolutionizing the way buildings are constructed but also contributing to a more sustainable future. As the construction industry embraces these advancements, we can expect to see a lasting impact on building practices around the globe.