The Importance of Gutter and Downpipe Roll Forming Machines in Modern Construction

In the ever-evolving landscape of the construction industry, efficiency, durability, and aesthetic appeal are paramount. Among the various tools and machinery that facilitate this, gutter and downpipe roll forming machines have emerged as indispensable assets. These machines are designed to create high-quality gutters and downpipes efficiently, ensuring that structures are well-protected from water damage while also contributing to their overall architectural beauty.

What is a Gutter and Downpipe Roll Forming Machine?

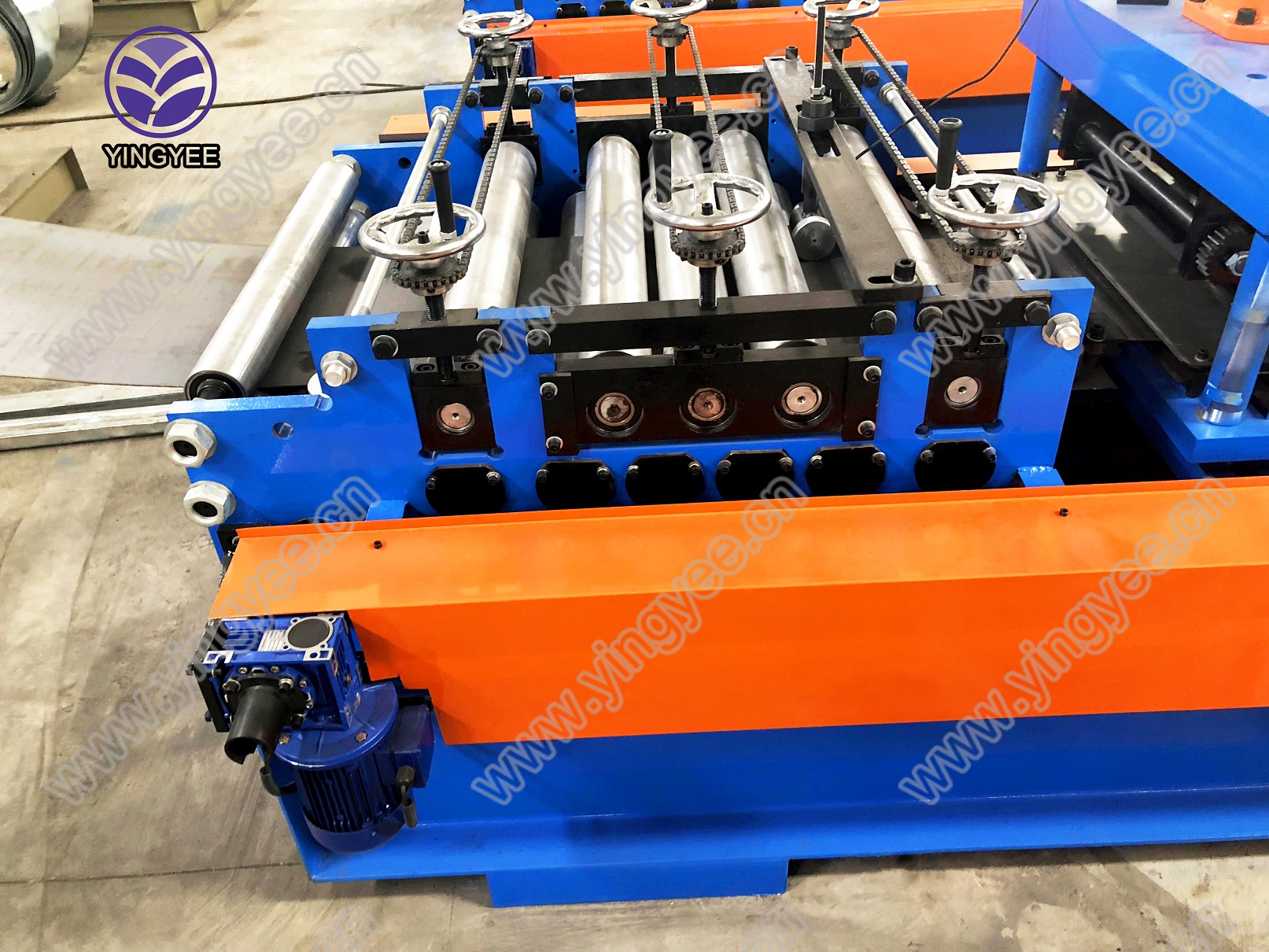

A gutter and downpipe roll forming machine is a type of industrial equipment used to produce continuous metal profiles for gutters and downpipes. Through a process known as roll forming, flat metal sheets are fed into a series of rollers that shape the material into the desired profiles. This process is highly efficient and allows manufacturers to produce large quantities of gutters and downpipes in minimal time.

The versatility of these machines means they can work with a variety of materials, including galvanized steel, stainless steel, aluminum, and copper. The choice of material depends on the specific requirements of the project, such as the expected weather conditions, desired appearance, and budget constraints.

Why are Gutter and Downpipe Systems Essential?

Gutters and downpipes serve a fundamental purpose in building construction managing rainwater drainage. Without an effective system in place, water can accumulate on roofs and cause significant damage, such as leaks, mold, and structural deterioration. Additionally, improper drainage can lead to erosion and flooding around the property's foundation, compromising its integrity.

Moreover, gutters and downpipes, when designed correctly, can enhance the aesthetic appeal of a building. With various styles, colors, and finishes available, these elements can complement a building’s design, contributing to its overall character.

The Manufacturing Process

The manufacturing process for gutters and downpipes using a roll forming machine is straightforward but requires precision. Initially, a coil of metal is placed into the machine, where it is unwound and fed into a series of rollers. These rollers incrementally shape the metal into the desired profile—typically a U-shape for gutters or a cylindrical shape for downpipes.

Once the shaping process is complete, the machine can cut the metal into specified lengths, ensuring consistency across all pieces produced. Advanced roll forming machines are equipped with computer controls that allow for quick adjustments, enabling manufacturers to customize profiles based on client specifications or changing market demands.

Advantages of Using Roll Forming Machines

1. High Efficiency Roll forming machines can operate at high speeds with minimal downtime, allowing manufacturers to meet large order demands without sacrificing quality. 2. Material Utilization The process produces minimal waste, as the manufacturing mechanism can be finely tuned to use the metal efficiently.

3. Durability The resulting gutters and downpipes are robust and capable of withstanding harsh weather conditions, ensuring longevity and reduced maintenance costs. 4. Customizability Manufacturers can easily adjust production processes to create custom profiles tailored to specific architectural styles or functional requirements.

5. Cost-Effectiveness While the initial investment in a roll forming machine may be significant, the long-term savings in labor and material costs often make it a wise financial decision.

Conclusion

The role of gutter and downpipe roll forming machines in modern construction cannot be overstated. They not only contribute to the structural integrity and durability of buildings but also enhance their visual appeal. As technology continues to advance, these machines are likely to become even more efficient and versatile, further solidifying their importance in the construction industry.

For manufacturers, investing in high-quality roll forming machinery is crucial to staying competitive in the market. With a reliable gutter and downpipe system in place, construction projects can ensure effective water management, ultimately protecting investments and enhancing property values. In a world increasingly focused on sustainability and efficiency, the gutter and downpipe roll forming machine represents a blend of innovation and necessity in the modern construction narrative.