Double layer roof sheet forming machines have revolutionized the construction industry by offering a versatile solution that enhances efficiency and flexibility in manufacturing various profiles. These machines are specifically designed to produce two different metal roof sheets in one production line, which makes them an invaluable asset for businesses seeking cost-effective methods to boost production capacity without compromising on quality.

The key to understanding the remarkable utility of double layer roof sheet forming machines lies in their design and operational capabilities. Equipped with advanced technology, these machines integrate precision engineering which ensures consistent product output whether you are manufacturing corrugated sheets, trapezoidal sheets, or any other custom profiles. Moreover, the transition between different sheet types is seamless, requiring minimal downtime and technical intervention, thanks to engineered solutions in modern control systems.

Professional expertise plays a critical role in maximizing the benefits drawn from such machinery. Users equipped with a thorough understanding of their operational parameters can optimize settings to enhance production speed, efficiency, and product durability. Investing time in staff training and maintenance can extend the lifecycle of these machines, thereby delivering long-term value beyond the initial procurement costs.

In terms of authoritativeness, reputable manufacturers provide comprehensive data, specifications, and compliance documents that adhere to international standards. From materials used in production to safety protocols, these documents ensure that buyers receive a machine that meets regulatory and customization requirements. Partnering with established manufacturers also provides access to expert consultations, which further strengthens the decision-making process. This reliance on expert advice and authoritative data ensures that businesses can trust the performance and reliability of the double layer roof sheet forming machines they invest in.

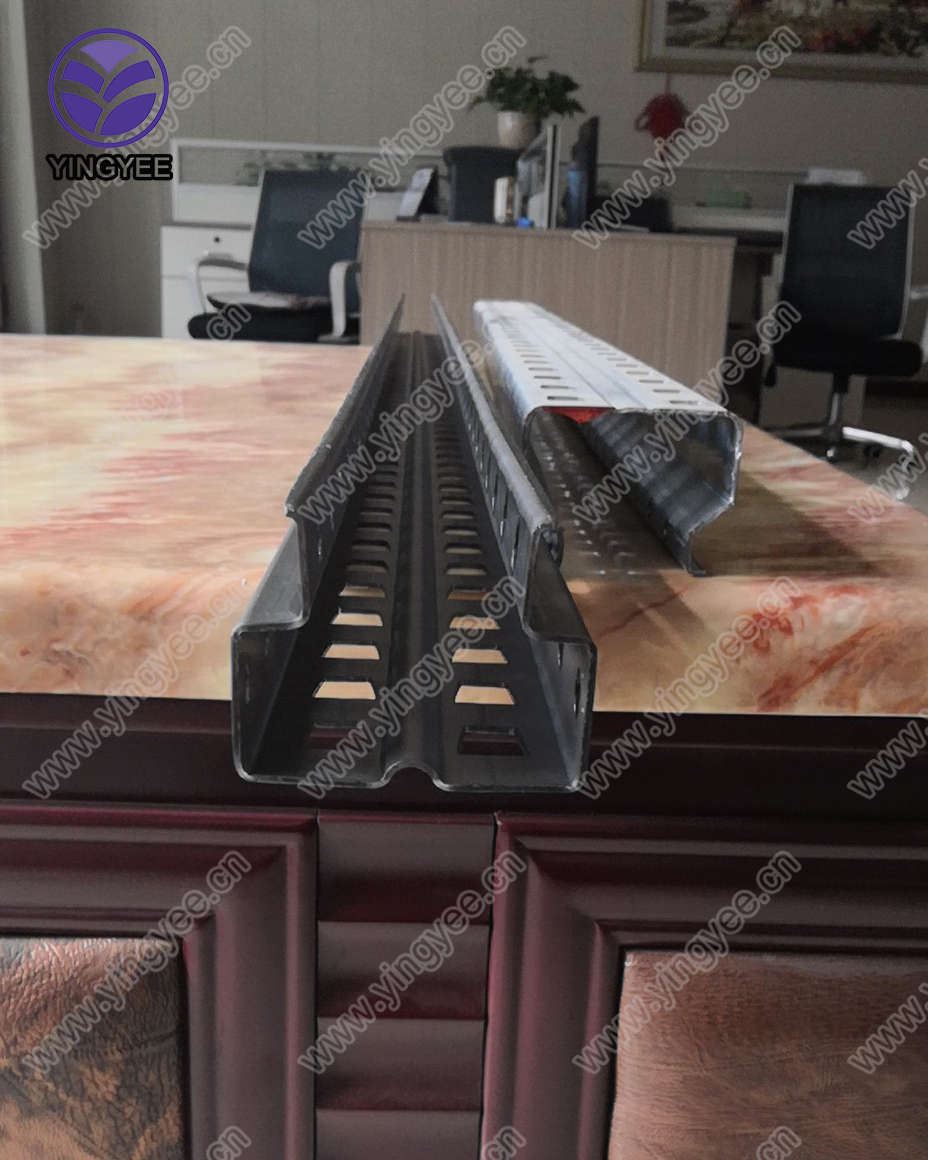

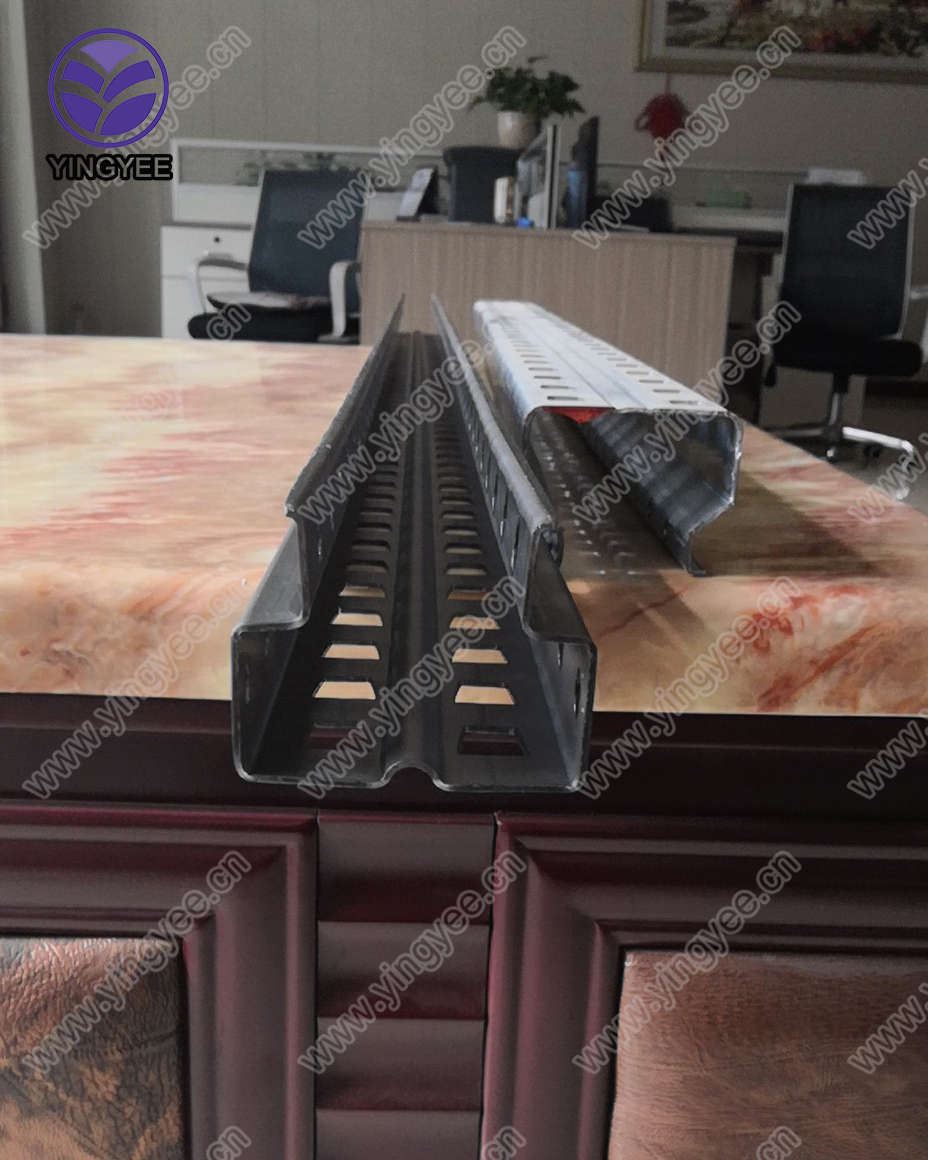

double layer roof sheet forming machine

Trustworthiness is a cornerstone in the adoption of any machinery, and certification is a testament to the credibility of double layer roof sheet forming machines. Top manufacturers often subject their machines to rigorous testing procedures that meet quality assurance benchmarks. This not only reassures purchasers of the machine's capabilities but also instills confidence that its operation will not subject them to unexpected mishaps or technical failures.

Moreover, customer reviews and case studies from past users can serve as valuable resources in evaluating the practicality and dependability of these machines. Satisfied customers who have experienced noticeable improvements in production efficiency and overall cost reduction often contribute to the credibility and perceived trustworthiness of double layer roof sheet forming machines.

In conclusion, double layer roof sheet forming machines represent a blend of experience, expertise, authority, and trust that makes them indispensable to the modern construction sector. By understanding their operational potential and partnering with reputable manufacturers and distributors, businesses can harness their full potential and achieve significant enhancements in production efficiency and product versatility. The key is to maintain a focus on continuous learning, machine maintenance, and adopting innovative practices that evolve with technological advancements and market demands.