The Rising Demand for Chicken Wire Mesh Making Machines

In recent years, the poultry farming industry has seen significant growth worldwide. This surge in demand has led to an increased focus on accessories and materials used in the industry, particularly chicken wire mesh. A chicken wire mesh making machine is an essential piece of equipment for producing this versatile fencing material, and its popularity is rising among manufacturers and poultry farmers alike.

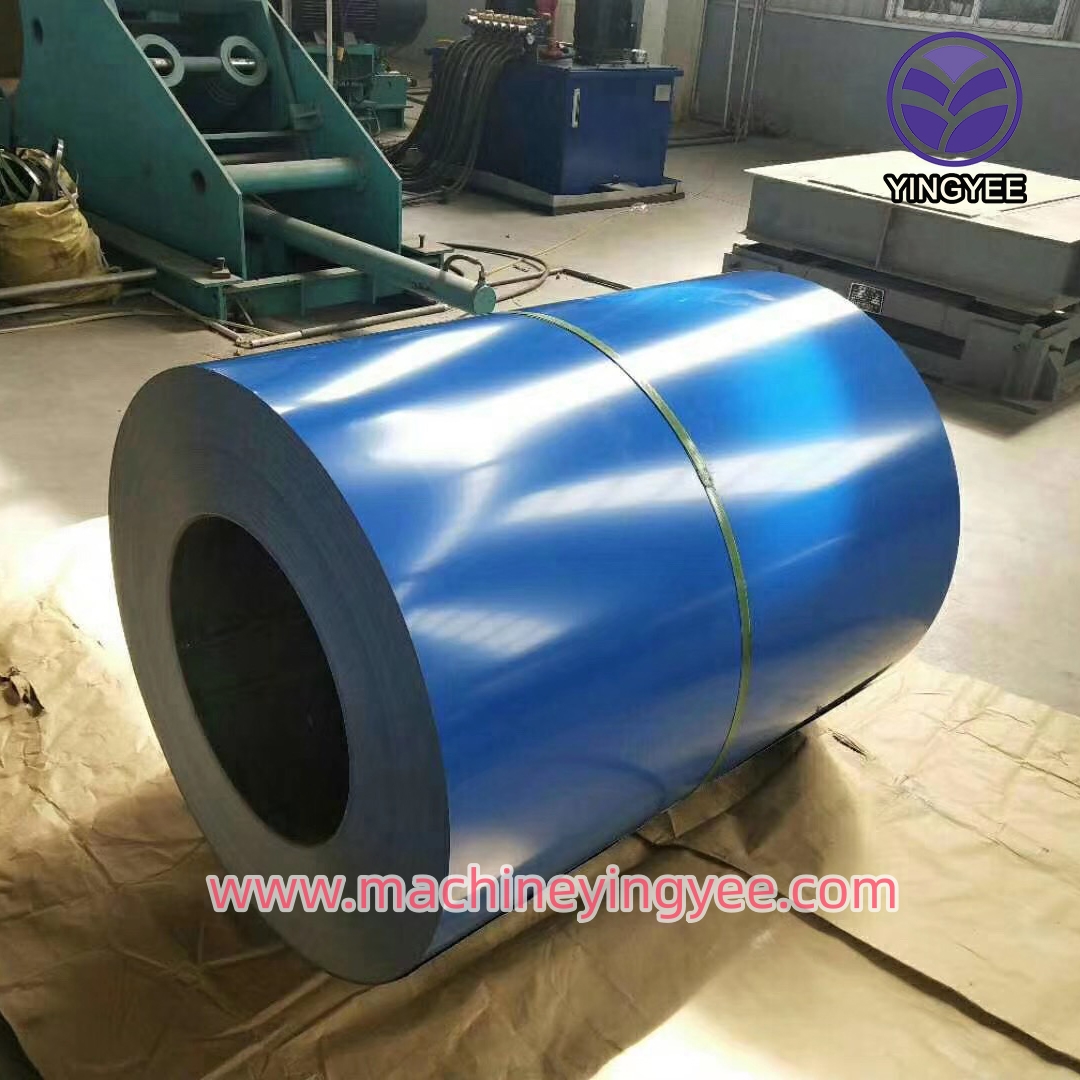

Chicken wire mesh, often made from galvanized steel, is primarily used for enclosures, supports, and protection of poultry. Its lightweight, durable, and flexible characteristics make it an ideal choice for creating safe and secure environments for chickens and other small animals. The mesh allows for adequate ventilation while preventing unwanted predators from gaining access to the birds. This balance of features has made chicken wire a staple in both commercial and residential poultry operations.

The process of manufacturing chicken wire mesh involves several key steps, including wire drawing, weaving, and the application of a protective coating. A chicken wire mesh making machine automates these processes, increasing efficiency and ensuring consistent quality. Modern machines are designed to handle various wire diameters, produce different mesh sizes, and can even apply coatings to enhance the wire's durability and resistance to rust and corrosion.

One of the primary advantages of investing in chicken wire mesh making machines is cost-efficiency. For poultry farmers or manufacturers producing large quantities of chicken wire, having in-house production capabilities can significantly reduce costs associated with purchasing pre-made mesh. This reduction in expenses can be particularly beneficial for small to medium-sized enterprises aiming to remain competitive in the market.

Moreover, owning a chicken wire mesh making machine allows for customization. Farmers can produce mesh tailored to their specific needs, whether that be in terms of size, strength, or coating. This flexibility not only caters to varying customer demands but also enables producers to differentiate their products, creating unique selling propositions that attract buyers.

The technological advancements in chicken wire mesh making machines have also contributed to their growing popularity. Recent innovations have introduced features such as computer numerical control (CNC) systems and automated operation, which simplifies the production process and enhances precision. These advancements allow manufacturers to produce high-quality products with minimal manual intervention, thereby reducing labor costs and human error.

As the poultry market continues to expand, the demand for chicken wire and, consequently, chicken wire mesh making machines will likely keep rising. Countries around the globe are witnessing an increase in poultry consumption due to population growth and rising incomes, further driving the need for efficient production equipment. Manufacturers must stay ahead of trends, investing in modern machinery that not only meets current needs but is also adaptable to future changes in production requirements.

In summary, the chicken wire mesh making machine plays a crucial role in the poultry farming industry. Its capacity to produce high-quality, cost-effective, and customizable wire mesh is invaluable to both manufacturers and farmers. As technology continues to evolve, these machines will only become more efficient, meeting the growing demands of a dynamic industry. Investing in a chicken wire mesh making machine today may very well lead to greater success tomorrow in an ever-expanding market.