The Rise of Light Gauge Steel Framing Machines

In the realm of modern construction, light gauge steel framing machines have revolutionized how structures are built, offering a blend of efficiency, precision, and sustainability. As the demand for innovative building solutions escalates, the construction industry has increasingly turned to light gauge steel (LGS) as a preferred material for framing. This shift is driven by the numerous advantages that LGS provides, including its strength, durability, and resistance to pests and fire. However, the true magic happens when these materials are processed using state-of-the-art framing machines.

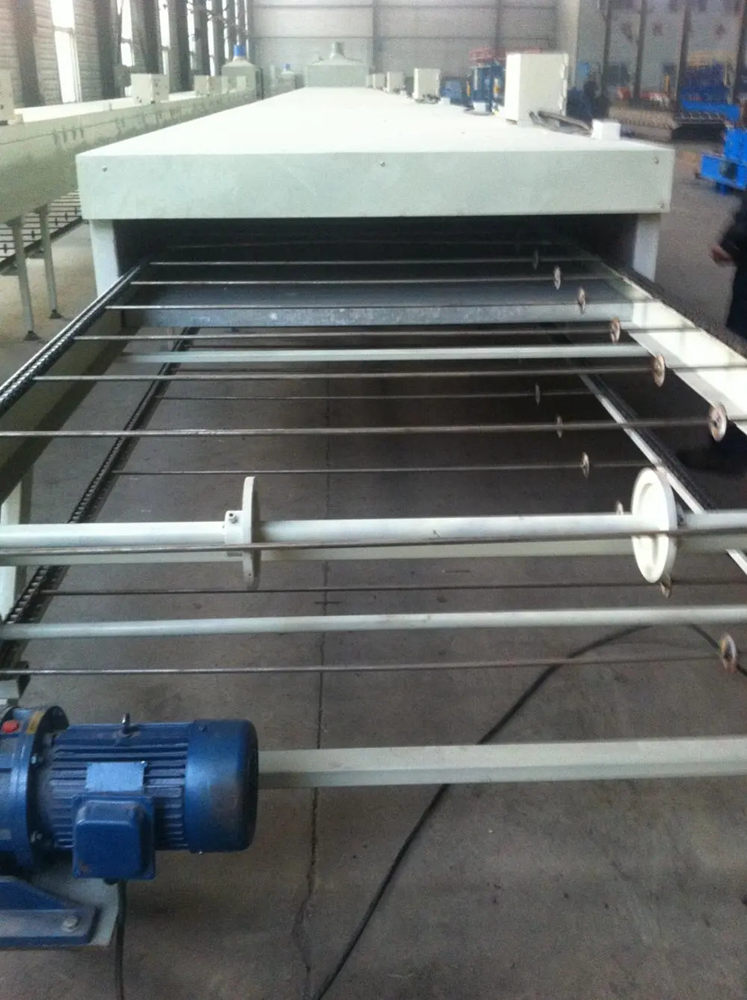

Light gauge steel framing machines are designed to automate and streamline the production of steel frames that serve as the skeleton of buildings. These machines utilize advanced technology to cut, bend, and assemble steel components precisely according to specified dimensions. The automation aspect drastically reduces labor costs and minimizes human error, allowing construction companies to deliver projects on time and within budget.

One of the significant benefits of using light gauge steel is its lightweight nature, which simplifies transportation and installation. The machines that fabricate these materials ensure that they are not only lightweight but also structurally robust, capable of supporting modern architectural designs. This is particularly valuable in large constructions where the weight of traditional materials could pose challenges.

Moreover, light gauge steel framing machines are versatile. They can produce components for various building types, including residential homes, commercial buildings, and industrial facilities. This versatility extends to the design possibilities, as LGS can be easily molded into complex shapes and structures. Architects and builders can take advantage of this flexibility to push the boundaries of creative design.

Sustainability is another crucial consideration in contemporary construction. Light gauge steel is often made from recycled materials and is itself fully recyclable, making it an eco-friendly choice. The efficiency offered by framing machines not only improves the construction process but also reduces waste and energy consumption. This aligns with the growing global emphasis on sustainable practices in all industries, including construction.

The integration of technology into light gauge steel framing has also paved the way for enhanced customization. With the support of computer-aided design (CAD) software, builders can create customized steel frames with intricate details that were once challenging to produce. These developments are indicative of a broader trend in the construction industry where technology enhances not just efficiency but also the quality of work produced.

As the industry continues to evolve, the demand for skilled operators to manage these light gauge steel framing machines grows. Training programs are increasingly becoming essential, ensuring that workers possess the necessary skills to effectively operate these advanced machines, while also emphasizing safety protocols.

In conclusion, light gauge steel framing machines are at the forefront of a construction revolution. By marrying traditional building practices with modern technology, these machines enhance the efficiency, sustainability, and design capability of construction projects. As the world moves toward smarter and more sustainable building solutions, the role of light gauge steel framing machines is likely to expand, setting the stage for a new era in construction that prioritizes innovation and environmental stewardship. The future of building is undoubtedly bright with the advent of this remarkable technology.