The Importance of Steel Cable Tray Making Roll Forming Machines

In the modern industrial landscape, the efficient management of electrical cables and wires is paramount. This has led to the proliferation of cable trays, essential components that support and organize cables in both commercial and industrial settings. Among the methods used to manufacture these trays, roll forming stands out as a highly effective and efficient process. In this article, we will delve into the significance of steel cable tray making roll forming machines, exploring their functionality, benefits, and impact on the industry.

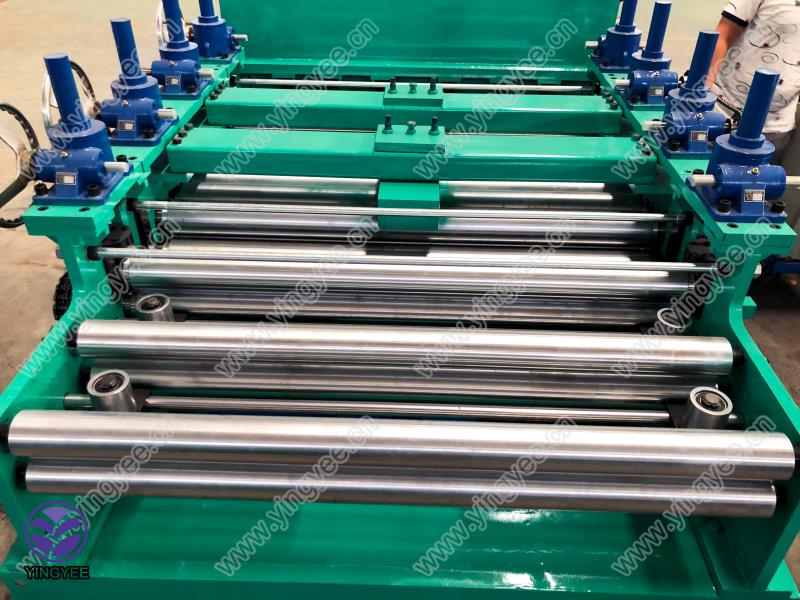

Understanding Roll Forming

Roll forming is a continuous bending process in which metal sheets or strips are passed through a series of rollers to achieve the desired cross-section. This method is particularly advantageous for manufacturing long lengths of uniformly shaped components, such as cable trays. The roll forming machine bends the steel into a shape suitable for carrying and organizing cables, while ensuring high precision and consistency.

Features of Steel Cable Tray Making Machines

Steel cable tray making machines come equipped with several key features that optimize their performance

1. High Precision These machines are designed to produce cable trays with exact dimensions, facilitating the proper installation of cables. The precise shaping helps to prevent cable damage from excessive bending or tight corners.

2. Flexibility Modern roll forming machines can produce various tray designs, including ladder trays, perforated trays, and solid trays. This versatility means manufacturers can meet diverse customer specifications without investing in multiple machines.

3. Automation Many roll forming machines are automated, allowing for minimal manual intervention. This not only enhances productivity but also reduces the risk of human error, ensuring a consistent product quality.

4. Durability Built primarily from high-strength steel, these machines can withstand the rigors of production while being resistant to wear and tear. The use of robust materials ensures a longer lifespan for the machinery and lower maintenance costs.

5. Energy Efficiency Advanced roll forming technologies incorporate features designed to reduce energy consumption, making the manufacturing process more sustainable and cost-effective.

Benefits of Using Steel Cable Tray Making Machines

There are numerous benefits associated with the implementation of steel cable tray making machines in production lines

1. Cost-Effectiveness Roll forming is an economical process due to its low material waste and high production speed. This translates into lower costs per unit, enabling manufacturers to remain competitive in the marketplace.

2. Enhanced Production Speed The continuous flow process of roll forming allows for the rapid production of cable trays. This efficiency is critical in industries where quick turnaround times are essential.

3. Quality Control The precision of roll forming facilitates the production of high-quality cable trays that adhere to industry standards. This ensures reliability in applications where safety and performance are critical.

4. Custom Solutions Manufacturers can design specific tray profiles according to customer requirements, enabling tailored solutions that meet precise operational needs.

Applications of Steel Cable Trays

Steel cable trays are widely used across various sectors, including

- Construction In both residential and commercial buildings, cable trays support electrical wiring, ensuring safe and organized installations.

- Manufacturing In industrial settings, cable trays manage electrical wiring for machines and equipment, facilitating maintenance and minimizing downtime.

- Telecommunications Cable trays are crucial for managing cables in data centers and telecommunication facilities, where organization and accessibility are vital.

Conclusion

The steel cable tray making roll forming machine is a vital asset in today's manufacturing landscape. Its ability to produce high-quality, precise, and varied cable trays efficiently positions it as an essential tool for industries reliant on effective cable management. With advancements in technology continually enhancing the capabilities of these machines, their importance is only set to grow, providing manufacturers with the means to meet increasing demands while maintaining quality standards. As organizations prioritize safety, efficiency, and sustainability, investing in roll forming technology for cable tray production is an opportunity that cannot be overlooked.