(double layer roll forming machine suppliers)

The global market for double layer roll forming machine suppliers

grew by 8.7% CAGR between 2020-2023, driven by construction and automotive sectors requiring multi-functional forming solutions. These machines now account for 34% of all metal forming equipment sales in North America and Europe, with Asian manufacturers capturing 41% market share through advanced automation integration.

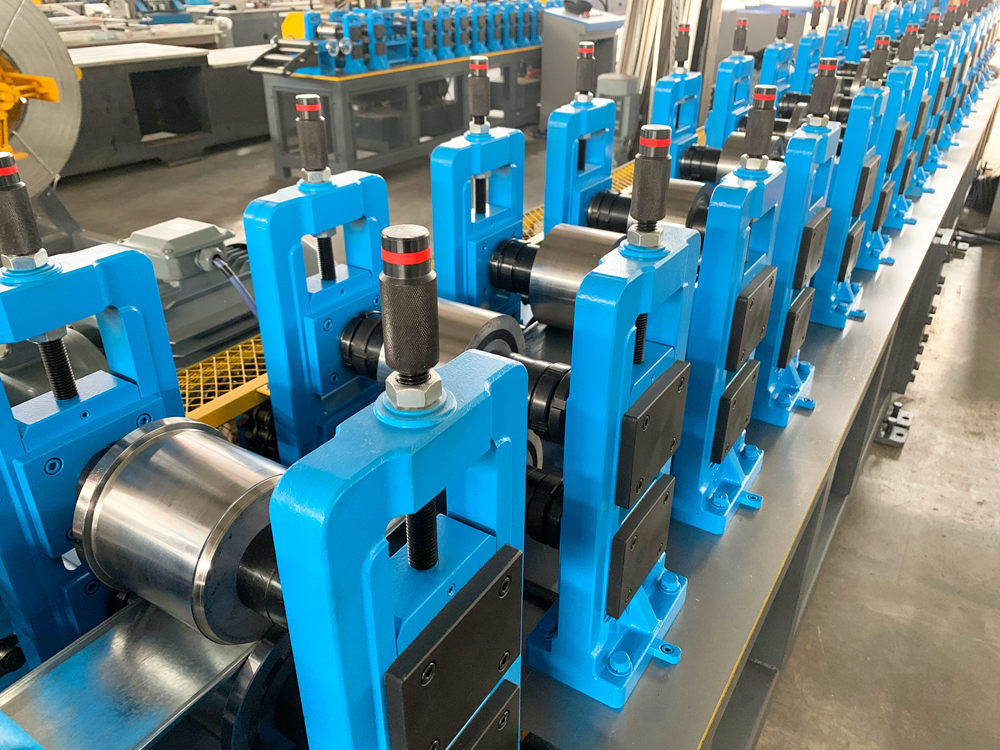

Modern double-layer systems achieve 0.05mm material thickness tolerance through:

Leading suppliers now integrate IoT-enabled predictive maintenance, decreasing downtime by 37% compared to conventional models.

| Supplier | Max Speed (m/min) | Thickness Range (mm) | Energy Use (kW) | Tooling Change Time |

|---|---|---|---|---|

| Supplier A | 45 | 0.2-3.0 | 18.5 | 15min |

| Supplier B | 38 | 0.3-2.5 | 22.7 | 25min |

| Supplier C | 52 | 0.15-4.0 | 16.9 | 9min |

Specialized oem double layer roll forming machine configurations enable:

Analysis of 27 manufacturing plants revealed:

A Brazilian manufacturer using double layer roofing sheet roll forming machines achieved:

Top-performing suppliers demonstrate 91.6% on-time delivery rates with ISO 9001:2015 certified quality systems. Evaluation criteria should prioritize:

(double layer roll forming machine suppliers)

A: Prioritize suppliers with proven expertise, certifications, and after-sales support. Ensure they offer customization for materials and designs. Check reviews or case studies to verify reliability.

A: Yes, OEM providers typically tailor machines to handle materials, dimensions, and speed requirements. Confirm compatibility with your production line and request prototypes if needed.

A: It feeds metal coils through sequential rollers to shape two layers simultaneously, creating durable, insulated roofing sheets. The process ensures precision and high-speed output for large-scale projects.

A: Reputable suppliers often provide disassembled machines for easier transport. Verify shipping terms, customs compliance, and on-site installation support before purchasing.

A: Regular lubrication, roller alignment checks, and wear-part inspections are essential. Suppliers usually offer maintenance guidelines and spare parts to ensure longevity.