Carbon Steel Welded Pipe Making Machine A Comprehensive Overview

Carbon steel welded pipe making machines are crucial for the efficient production of high-quality welded pipes used in various industries, including construction, oil and gas, and automotive. These machines employ advanced technology that ensures precision and durability in pipe manufacturing, catering to the rising demand for steel pipes worldwide.

The process begins with the selection of high-grade carbon steel strips, which are fed into the machine. The welded pipe making machine typically comprises several vital components, including uncoilers, straighteners, roll formers, welding units, and cutting systems. Each component plays an integral role in determining the overall efficiency and quality of the production line.

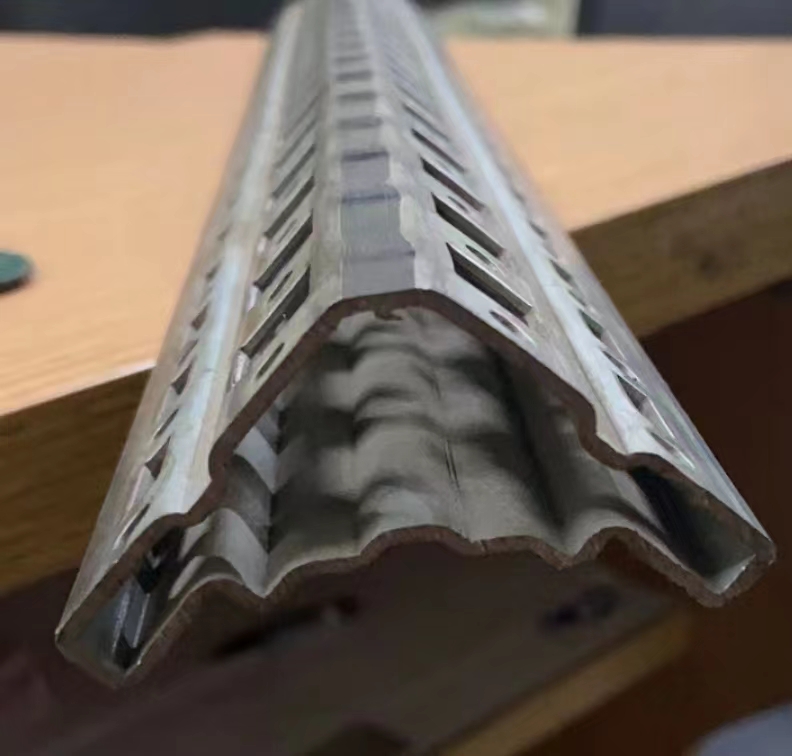

First, the uncoiler unwinds the steel strip, allowing it to be straightened to remove any coiling defects. The straightened strip is then guided through a series of rollers that gradually form it into a cylindrical shape. The roll forming process is critical as it determines the pipe's final dimensions, ensuring uniformity and precision.

Once the metal strip is adequately formed into a tube, the edges are prepared for welding. Advanced machines often utilize high-frequency induction welding or ERW (Electric Resistance Welding) techniques, which are known for their speed and robustness. These methods allow for a strong and continuous weld along the length of the pipe, ensuring excellent structural integrity.

After the welding process, the pipes undergo a cooling phase and are reviewed for any signs of defects. Quality control is paramount, as the integrity of welded pipes is essential for their intended applications. Various tests may be conducted, such as hydrostatic tests and visual inspections, to ensure that each pipe meets industry standards.

In terms of efficiency, modern carbon steel welded pipe making machines are designed for high-speed production, with the capability to operate 24/7. Automation technology plays a significant role in enhancing productivity, allowing for minimal human intervention and reduced operational costs. Additionally, many machines are equipped with PLC (Programmable Logic Controller) systems that facilitate better monitoring and control of the manufacturing process.

Moreover, sustainability has become a crucial factor in pipe production. Manufacturers are increasingly focusing on energy-efficient machines and processes that reduce wastage and environmental impact. By integrating recycling systems and using renewable energy sources, companies can contribute to a greener manufacturing sector.

In conclusion, the carbon steel welded pipe making machine is a sophisticated piece of equipment that not only enhances the manufacturing process but also ensures the production of high-quality welded pipes essential for numerous industries. As technology continues to evolve, these machines will likely see further advancements, improving performance and sustainability in the steel pipe sector. The investment in such machinery is vital for companies looking to meet the growing demands of the global market while maintaining high standards of quality and efficiency.