The Importance of 100-600% Cable Tray Machine in Modern Industries

In today's rapidly evolving industrial landscape, the integration of efficient machinery plays a pivotal role in enhancing productivity and ensuring safety. One such essential piece of equipment is the cable tray machine, specifically designed to handle a range from 100% to 600% cable trays. Understanding its functionality, benefits, and applications can provide valuable insights for industries reliant on effective cable management.

What is a Cable Tray Machine?

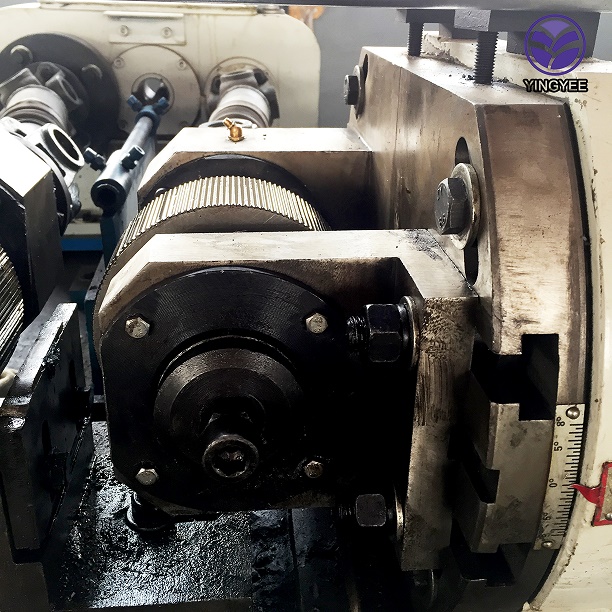

A cable tray machine is a specialized piece of manufacturing equipment used for producing cable trays, which are structural systems that support insulated electric cables used for power distribution and communication. These trays can vary significantly in size, shape, and capacity, depending on their intended use. The range of 100% to 600% typically refers to the machine’s production capability, meaning it can efficiently handle cable trays of different dimensions and weights.

Key Features and Functionality

The 100-600% cable tray machine is engineered for versatility, allowing for the production of various tray sizes with minimal adjustments. It typically includes features such as

1. High-Speed Production These machines are designed to operate at elevated speeds, reducing lead times significantly. 2. Precision Engineering Advanced technology ensures that each tray produced meets exact specifications, which is crucial for installation safety and compliance with industry standards.

3. Material Handling The machine can work with a variety of materials including steel, aluminum, and fiberglass, making it adaptable for several applications.

4. Easy Operation Many models come with user-friendly interfaces, making it easier for operators to adjust settings and monitor production.

5. Durability and Maintenance Built to withstand the rigorous demands of production environments, these machines often feature robust construction and require minimal maintenance.

Benefits of Using Cable Tray Machines

1. Enhanced Efficiency By automating the production of cable trays, manufacturers can significantly improve operational efficiency. The ability to produce trays at various sizing options without extensive retooling saves time and reduces labor costs.

2. Cost-Effectiveness The initial investment in a high-quality cable tray machine is offset by reduced material waste and lower labor costs over time. Higher production rates and lower overheads contribute to an improved bottom line.

3. Safety Compliance With quality control built into the production process, businesses can ensure that the trays meet all safety and regulatory standards, reducing the risk of hazards associated with electrical installations.

4. Flexibility in Production The ability to switch between different tray sizes and styles easily means that manufacturers can adapt to market demands without needing multiple machines.

Applications in Various Industries

The versatility of the 100-600% cable tray machine makes it suitable for numerous industries

- Construction In infrastructural projects, cable trays are crucial for organizing electrical and communication systems within buildings. - Telecommunications As networks expand, proper support for cabling is essential to ensure signal strength and reliability.

- Manufacturing Factories require extensive wiring for machinery and safety systems; cable trays provide a safe and organized method to run these cables.

- Energy In power plants and renewable energy systems, cable management is crucial for operational efficiency and safety.

Conclusion

The 100-600% cable tray machine epitomizes the intersection of technology and industry needs, providing efficient solutions for cable management challenges. As industries continue to grow and evolve, the role of such machinery becomes increasingly vital. Investing in advanced cable tray production technology is not just a step towards modernization; it is an essential move to enhance safety, efficiency, and sustainability in today's competitive market landscape. Embracing these technologies will not only streamline production processes but also position companies for success in the future.