The steel industry, a backbone of modern manufacturing, continually evolves with technological advancements. Among the pivotal machinery in this sector is the straighten and cutting machine for steel coil. This equipment plays an essential role in ensuring the precision and quality of steel products, and understanding its operation brings about significant enhancements in productivity and quality control.

A straighten and cutting machine for steel coils is specifically designed to handle the complexity of processing coiled steel, an essential raw material for various industrial applications. This machine integrates advanced technology to align and cut steel coils to specified dimensions, ensuring uniformity and reducing wastage, a critical factor in cost management.

Drawing from real-world experience in steel manufacturing, a key benefit of these machines is their ability to enhance operational efficiency. Production processes that once took numerous manual interventions are now streamlined, cutting down production time significantly. For instance, in a case study involving a major automobile manufacturer, the introduction of an automated straighten and cutting machine reduced their processing time by 40%, allowing for quicker turnaround times in their assembly lines.

From a technical standpoint, expertise in operating these machines involves understanding the dynamics of tension control and precision cutting mechanisms. Tension control is crucial as it keeps the steel flat during the cutting process, preventing any buckling or deformation that could compromise the integrity of the steel sheets. A deeper insight into the software interface that controls these parameters can further enhance precision, leading to lesser material wastage and higher quality outputs.

Authoritative knowledge in the field suggests that the selection of a straighten and cutting machine should be based on specific production requirements. Industry leaders recommend machines equipped with servo controls and automatic coil loading systems. Such features not only improve accuracy but also enhance safety by minimizing manual handling of heavy coils, thereby reducing workplace accidents, a critical consideration in occupational health and safety regulations.

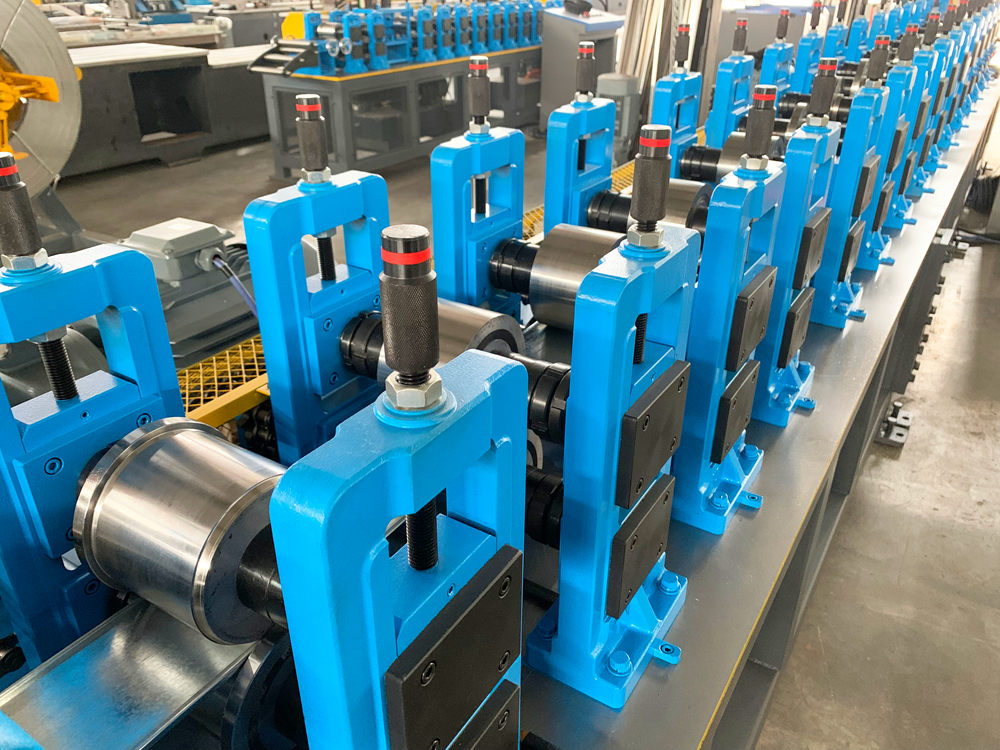

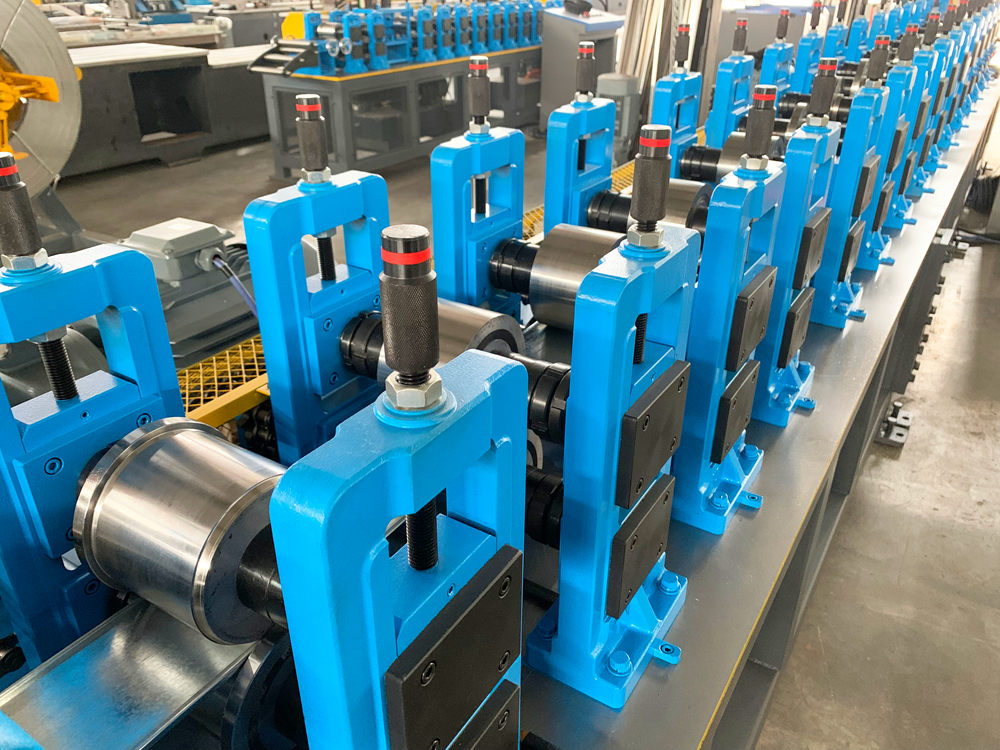

straighten and cutting machine for steel coil

Furthermore, trustworthiness in equipment performance is paramount. Manufacturers of these machines often provide detailed documentation and after-sales support, which is vital for long-term reliability and performance. Selecting a machine from a reputable brand known for rigorous quality testing and compliance with international manufacturing standards assures consistent results over extended periods.

In terms of maintenance, these machines are designed with user-friendly interfaces, allowing for regular diagnostics and upkeep without requiring extensive technical expertise.

Routine maintenance is critical to prevent downtimes and ensure the machinery operates at peak efficiency. A comprehensive maintenance schedule, as advised by the manufacturer, can extend the lifespan of these machines, ensuring they meet production demands continuously.

For companies aiming to invest in a straighten and cutting machine for steel coils, a comprehensive assessment of their production needs is advisable. Understanding coil dimensions, thickness ranges, and desired production speeds can guide the purchasing decision, ensuring the machine aligns with their operational objectives.

In conclusion, the straighten and cutting machine for steel coils is an indispensable asset in modern manufacturing, offering enhancements in productivity, precision, and safety. Its deployment requires a combination of experiential insight, technical expertise, authoritative guidance, and a commitment to trustworthy practices. As industries continue to advance, embracing such technologies will undoubtedly lead to more efficient and competitive manufacturing solutions.