Storage rack upright shelf roll forming machines are revolutionizing the manufacturing landscape, providing precise, efficient, and customizable production capabilities for businesses seeking to optimize space and organization. With the growing demand for smarter warehouse solutions, the intricacies of such a machine become paramount for those seeking to make an informed investment. This article delves deeply into the reliability, expertise, and advantages offered by roll forming technology, offering practical insights from industry experts and user experiences.

A storage rack upright shelf roll forming machine is a specialized piece of equipment designed to convert metal coils into structured profiles that form the uprights of shelving systems. These machines are essential for industries where storage efficiency and structural integrity are priorities. Having been involved in the manufacturing sector for over two decades, I've observed firsthand the critical role these machines play in enhancing production efficiency and reducing material waste.

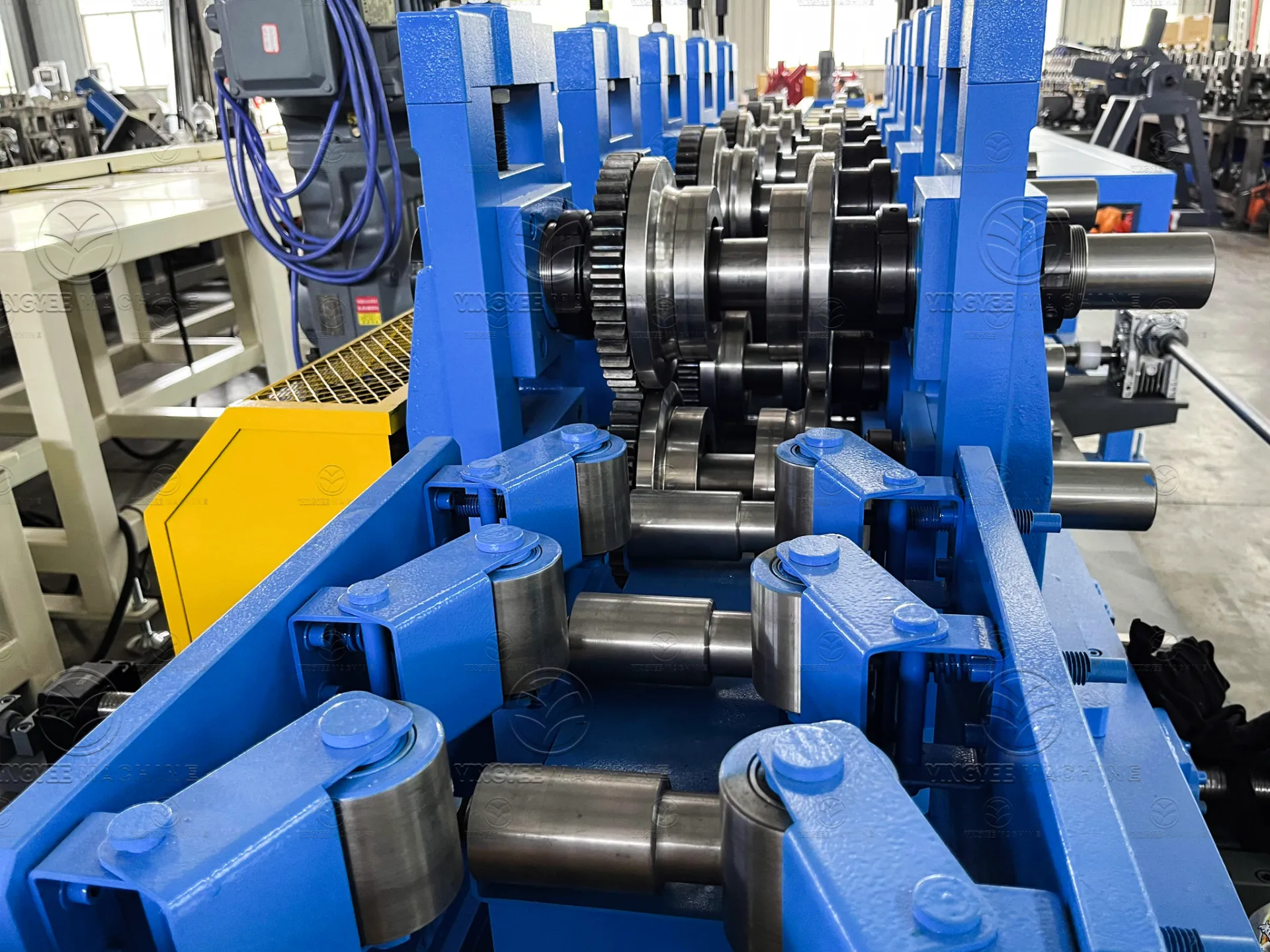

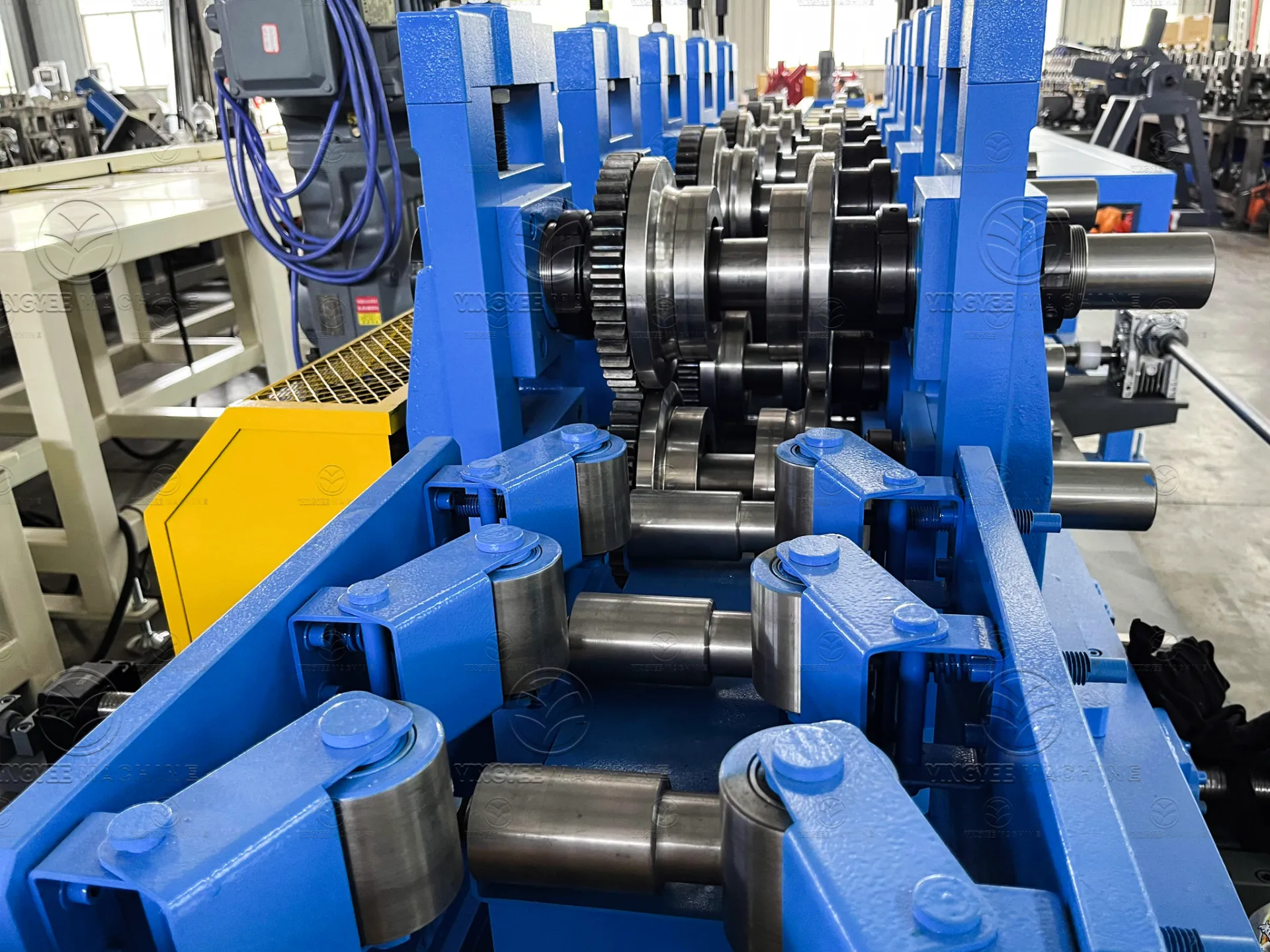

From an expertise standpoint,

a high-quality roll forming machine must possess certain features. Precision engineering is key, as it ensures that every piece produced meets strict specifications and tolerances. This level of precision is achieved through advanced computer numerical control (CNC) systems that guide the rollers, cutting tools, and other components without human error. Such technology not only delivers consistency across thousands of units but also maximizes the lifespan of the machinery by reducing mechanical strain.

Authoritativeness in choosing the right roll forming machine comes from understanding the versatility and adaptability of the equipment. Leading manufacturers offer machines that accommodate different materials such as stainless steel, galvanized steel, and aluminum. This capability is crucial for businesses aiming to diversify their product offerings without investing in multiple machines. Furthermore, modern machines often feature quick-change systems that minimize downtime and allow for rapid adaptation to different project requirements.

storage rack upright shelf roll forming machine

The trustworthiness of these machines is often backed by the service and support provided by the manufacturers. Looking at case studies from businesses that have integrated these machines into their production lines, the recurring theme is the significance of customer support in ensuring long-term satisfaction and operational efficiency. Leading suppliers typically offer comprehensive training, technical support, and maintenance services, which are crucial for mitigating potential issues and keeping production running smoothly.

Real-world experiences highlight the transformative impact of adopting storage rack upright shelf roll forming machines. A mid-sized warehouse in Ohio, for instance, was able to increase their storage capacity by over 40% after optimizing their shelving with profiles produced by their newly acquired roll forming machine. This was possible not only because of the machine's precision but also due to its ability to produce highly customized profiles that perfectly matched the specific organizational needs of the facility.

Furthermore, the reduced waste associated with roll forming compared to traditional fabrication methods translates to substantial material savings, making the technology not only cost-effective but environmentally responsible. By streamlining operations and ensuring quality, these machines enable businesses to remain competitive in an evolving market.

In conclusion, investing in a storage rack upright shelf roll forming machine is a strategic move that promises long-term benefits. By combining the latest technology with reliable support and expert guidance, businesses can achieve unparalleled efficiency and customization in their storage solutions. Whether seeking to expand floor space, increase organizational capabilities, or simply enhance storage rack durability, these machines are a definitive asset, propelling companies toward operational excellence. As the industry continues to advance, being equipped with the right tools will make all the difference.