If you're navigating the industrial landscape of manufacturing and warehouse management, storage rack and beam roll forming machines are pivotal in optimizing space and enhancing operational efficiency. These machines have revolutionized how businesses approach storing and organizing goods, providing customizable, robust solutions tailored to individual requirements.

Drawing from over a decade of experience in industrial machinery procurement, it's evident that the choice of a roll forming machine can significantly impact operational workflows and long-term profitability. The core advantage lies in the machine's ability to fabricate customized storage solutions that perfectly align with spatial constraints and load requirements.

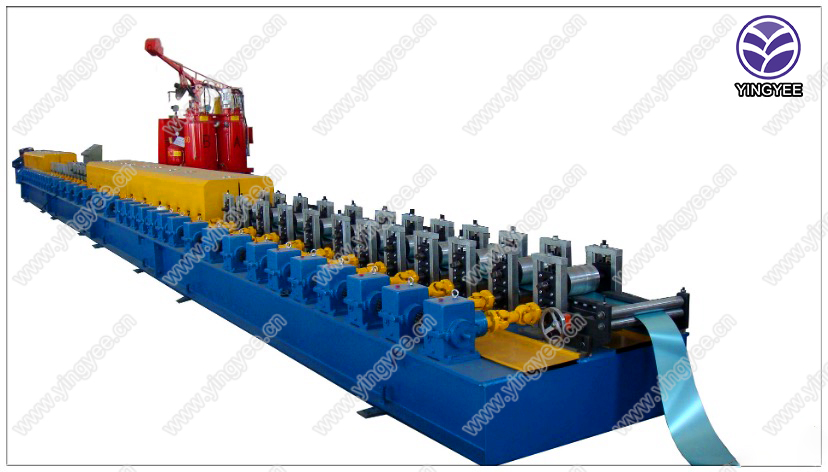

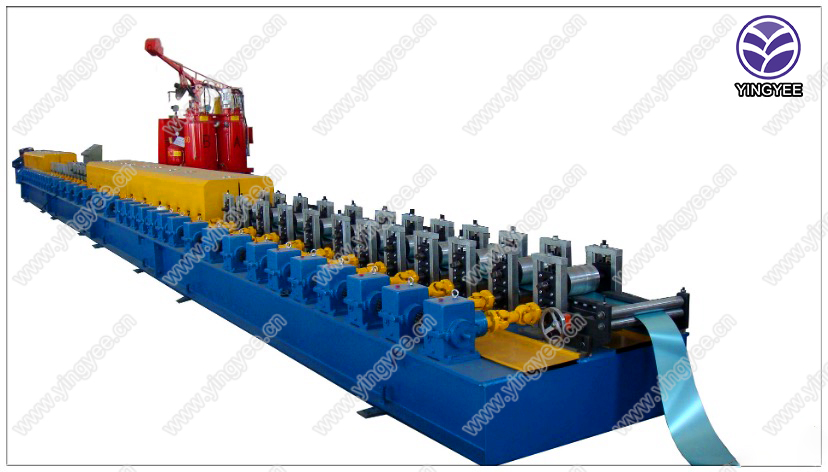

A storage rack and beam roll forming machine operates through a series of continuous bending processes, transforming metal coils into desired shapes with precision. The flexibility of these machines allows the creation of beams of various lengths, thicknesses, and profiles, catering to different weight-bearing needs. For companies prioritizing scalability, this adaptability ensures seamless integration with existing systems, thereby mitigating the disruptive challenges associated with warehouse expansion.

When considering expertise in the industry, manufacturers emphasize the precision engineering of these machines. These state-of-the-art devices are equipped with advanced control systems, ensuring the highest degree of accuracy in product dimensions. This accuracy is critical, especially when racks must fit within stringent spatial layouts typical in metropolitan warehouses. The precise configuration reduces the likelihood of costly errors, which can impede warehouse operations and affect stock management.

Furthermore, authoritativeness in utilizing storage rack and beam roll forming machines comes from understanding the intricacies of material properties and tolerances. Engineers must consider factors such as tensile strength and elasticity when selecting metal coils to ensure the durability and longevity of the produced racks. Incorrect gauge measurements or material selection can lead to product failure, posing significant safety hazards and financial liabilities.

storage rack and beam roll forming machine

Trustworthiness in this domain is paramount. It is achieved through rigorous compliance with industry standards and certifications.

Users must verify that their roll forming machines meet international safety regulations, such as ISO and CE standards. Regular maintenance and service checks go a long way in preventing downtime, which is crucial for maintaining inventory flow and meeting market demands.

Investments in storage rack and beam roll forming machines not only streamline space utilization but also enhance storage efficiency, DEX (daily efficiency index), and fulfillment velocity. These outcomes are vital in large-scale operations where time is of the essence, and delays can have sweeping repercussions across supply chains. Investing in high-quality machinery ensures reduced lead times and boosts client satisfaction by facilitating faster, more accurate order fulfillment.

For enterprises seeking to remain competitive in a dynamic market, sustainability features of modern roll forming machines play a critical role. Many manufacturers now focus on eco-friendly designs that minimize energy consumption and waste production. This is not only a commitment to environmental stewardship but also a practical business strategy, reducing operational costs and supporting companies' eco-certified marketing efforts.

Moreover, as businesses evaluate the total cost of ownership, the automation potential of these machines cannot be overlooked. Automated roll forming machines increase production rates while minimizing labor costs, thus offering a compelling value proposition. Incorporating smart technology enhances real-time monitoring and predictive maintenance capabilities, ensuring that the machinery operates at peak efficiency with minimal intervention.

In conclusion, acquiring a storage rack and beam roll forming machine is a strategic investment that promises robust returns in operational efficiency and space management. Its role in shaping the future of warehouse optimization is undeniable, providing customizable, accurate, authoritative, and environmentally sustainable solutions tailored to meet the evolving demands of modern industry. The commitment to quality and compliance underscores the reliability and trustworthiness that businesses seek in a perilous yet promising industrial landscape.