Steel stud making machines represent a pivotal advancement in modern construction, significantly impacting the building industry with their precision, efficiency, and versatility. These machines are essential for manufacturing steel studs, which form the backbone of contemporary structures due to their strength, durability, and adaptability.

The process begins with the selection of high-quality steel, ensuring that the final product meets industry standards for structural integrity.

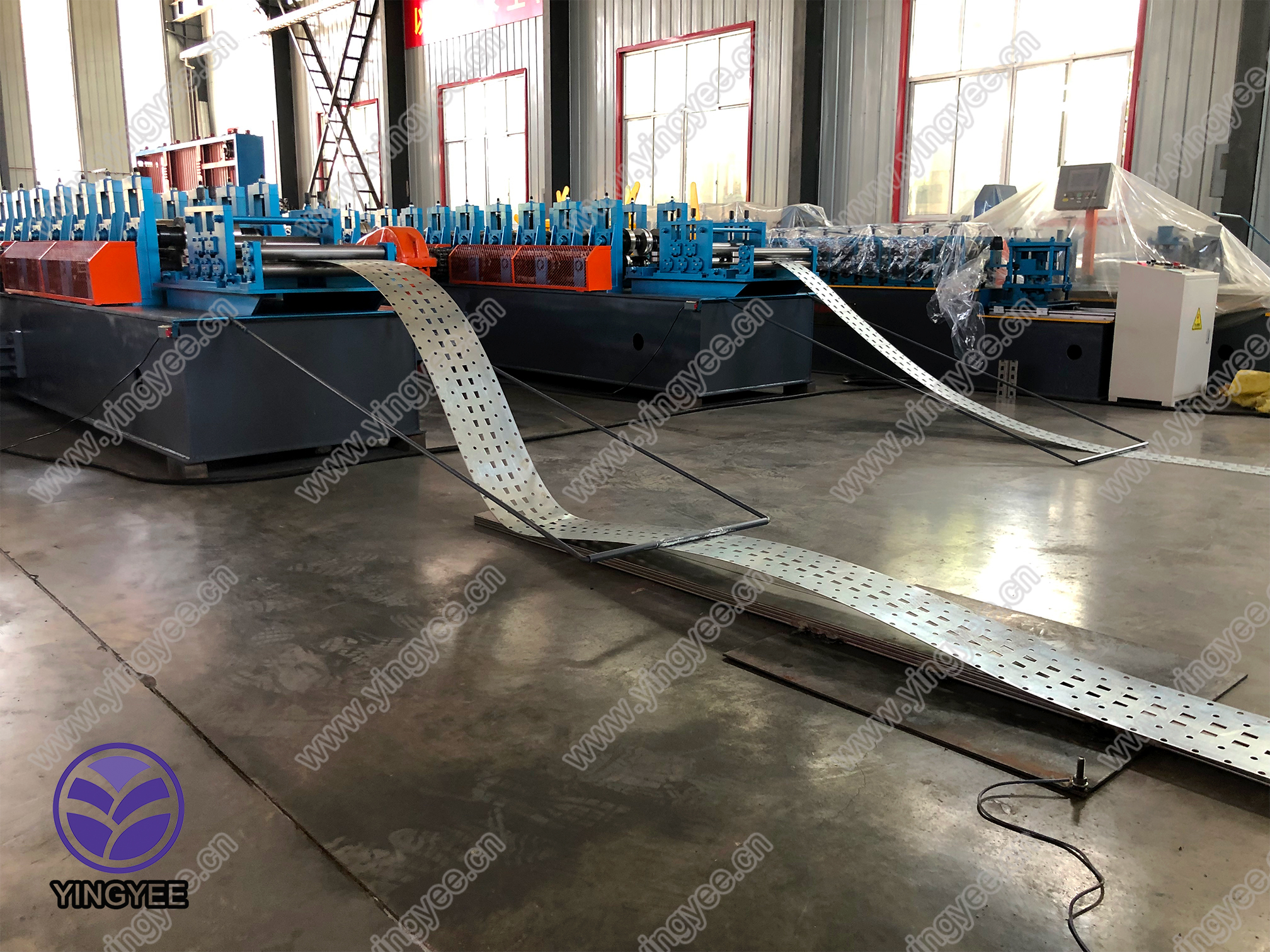

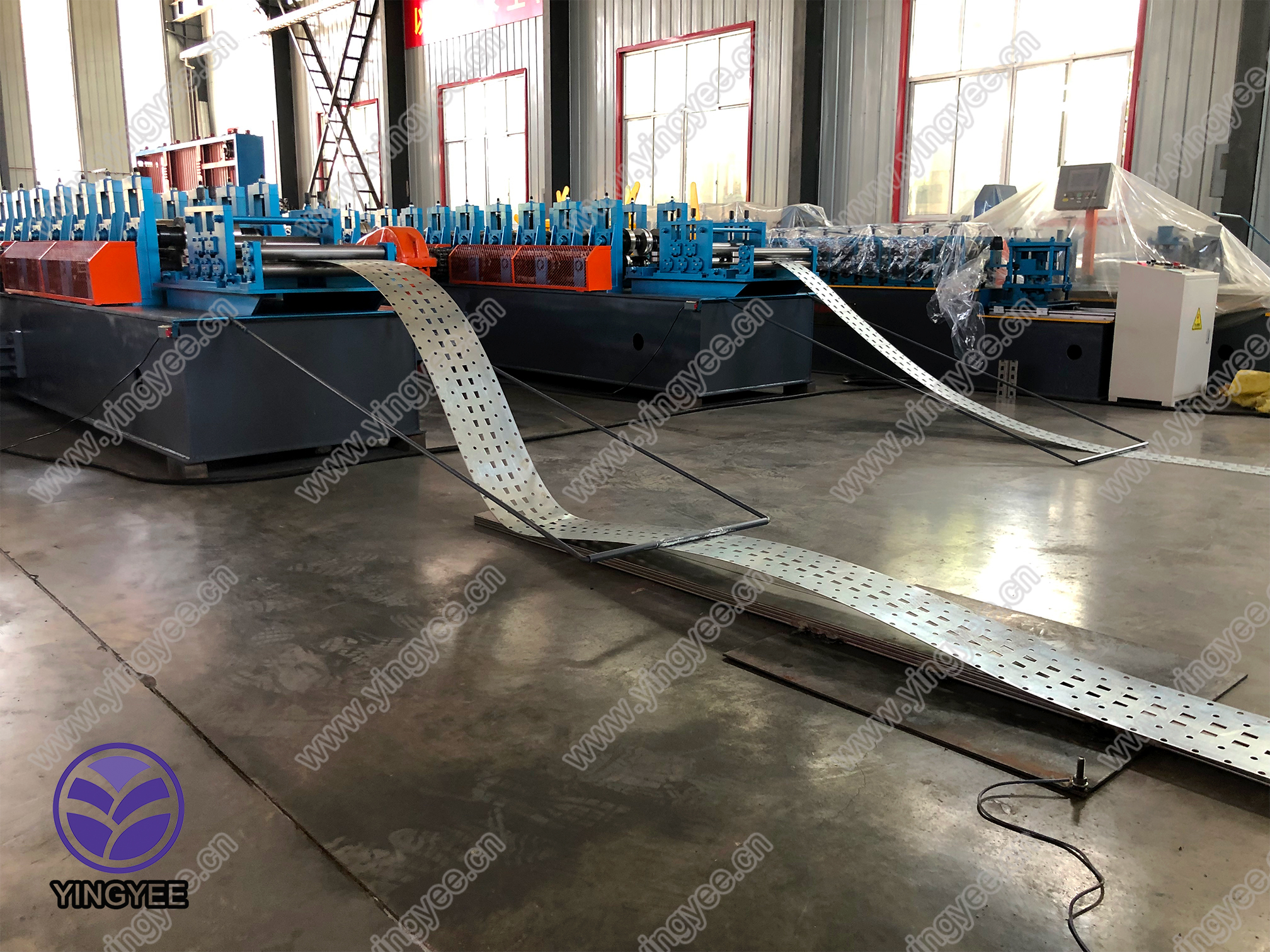

Steel stud making machines utilize a roll forming process, in which steel is passed through a series of rollers to achieve the desired shape and size. This high-speed operation not only increases production efficiency but also minimizes waste, a crucial factor in sustainable building practices.

Professionals with extensive experience in construction engineering often laud the adaptability of steel stud machines. These machines can be programmed to create studs of varying lengths, widths, and thicknesses, meeting the specific needs of any project. This customization capability is vital for accommodating diverse architectural designs and structural requirements, making steel stud machines invaluable for both residential and commercial construction projects.

Expertise in operating these machines is essential to maximize their potential. Skilled technicians ensure that each machine is calibrated correctly and maintained regularly to prevent costly downtime and maintain production quality. Moreover, these experts are adept at adjusting machine settings to align with evolving building regulations and material innovations, ensuring compliance and optimizing production efficiency.

The authority of steel stud making machines in the construction industry is undisputed, supported by the endorsement of leading architects and builders worldwide. The consistency and reliability of the studs manufactured by these machines contribute significantly to their reputation, as they often exceed the performance of traditional wooden studs in load-bearing capacity and resilience against environmental factors such as moisture and fire.

steel stud making machine

Trust in steel stud making machines is reinforced by rigorous testing and certification processes. Manufacturers subject their machines to stringent quality control measures, often in line with ISO standards, to ensure that every stud produced meets precise design specifications and safety standards. This dedication to quality reassures builders and consumers alike, fostering confidence in the longevity and safety of structures built with steel studs.

In the ever-evolving world of construction technology, the ongoing innovation of steel stud making machines demonstrates an unwavering commitment to improving building practices. Not only do these machines enhance production capabilities, but they also contribute to the broader goals of sustainability and resource efficiency. By reducing material waste and enabling the use of recyclable materials, steel stud machines play a critical role in promoting environmentally responsible construction.

For industry professionals seeking to integrate steel stud making machines into their operations, it's crucial to remain informed about the latest technological advancements and industry trends. Attending industry conferences, engaging in continuous professional development, and collaborating with leading manufacturers are effective strategies to stay at the forefront of this rapidly progressing field.

The role of steel stud making machines extends beyond just manufacturing; they symbolize a shift towards more innovative, efficient, and sustainable construction practices. By investing in these machines and harnessing their capabilities, builders can achieve unprecedented levels of precision and quality in their projects, paving the way for a future where steel studs are synonymous with excellence in construction.

This comprehensive understanding and integration of steel stud making technology underscore the importance of experience, expertise, authoritativeness, and trustworthiness, ensuring that each machine continues to deliver exceptional results across diverse construction landscapes.