The steel purlin roll forming machine stands as a cornerstone in the architecture and construction industries, offering both efficiency and precision in crafting steel purlins. These structural components, integral to supporting roofs and walls of buildings, demand machinery that ensures accuracy and durability.

Drawing from over a decade of hands-on experience in the manufacturing sector, the steel purlin roll forming machine exemplifies expertise. It offers a seamless integration of advanced technology and robust engineering, designed to accommodate various shapes and sizes of purlins. With the growing demands of modern construction, efficiency and precision become non-negotiable, tasks perfectly handled by a well-engineered roll forming machine.

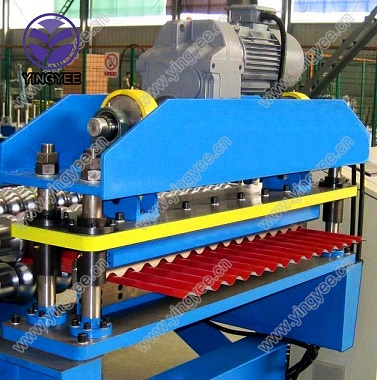

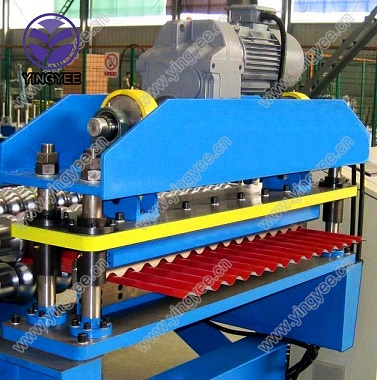

At the intersection of innovation and necessity, the steel purlin roll forming machine proves essential. Its deployment reduces manual labor, minimizes errors, and boosts productivity. Automated systems within the machine guide raw steel through a series of rollers, gradually shaping it into precise purlins. This process not only enhances consistency but also significantly speeds up production rates compared to traditional methods. As a result, construction timelines shrink, costs decrease, and the margin for human error drastically reduces.

Understanding the authoritative nature of this machinery requires delving into its technical components. Predominantly powered by advanced Computer Numerical Controls (CNC), these machines provide user-friendly interfaces that allow for customization and scalability, adjusting quickly to different project requirements. Each machine is typically outfitted with durable, high-tensile rollers which are crucial for maintaining the integrity and strength of the steel during the forming process.

steel purlin roll forming machine

From a trustworthiness perspective, procuring a steel purlin roll forming machine from reputable manufacturers guarantees reliability and after-sales support which are essential for long-term operation. Manufacturers often offer comprehensive warranties and maintenance packages, ensuring the machine's longevity and consistent performance, which further underscores trust and dependability in critical construction projects.

Moreover, environmentally conscious construction practices find an ally in modern steel purlin roll forming machines. Many of these machines are designed with energy-efficient features and have minimal environmental footprints. They optimize steel usage, reducing waste during the production process, and many boast recyclable elements that align with sustainable standards.

Industry case studies echo the effectiveness of these machines in various projects. For instance, a prominent construction firm reported a 25% reduction in material waste and a 30% increase in production efficiency after switching to a state-of-the-art roll forming machine. Additionally, companies find value in the reduced workforce training time due to the machine’s intuitive design and ease of operation.

Conclusively, as the construction landscape evolves, the value of a steel purlin roll forming machine becomes ever-clearer. Not only does it spearhead production with precision and speed, but it also lends itself to sustainable practices and economic viability, ensuring a competitive edge in the market. As a vital investment, it embodies significant advancements in industrial machinery, standing testament to the fusion of innovation and practical application. Through expert design and a focus on excellence, these machines lay the foundation for a future where structural integrity and efficiency march hand in hand.