Square downpipe roll forming machines have become pivotal in manufacturing industries that focus on efficient and precise sheet metal fabrication. As experts in industrial machinery continually advance, these machines stand out by offering specialized capabilities that streamline production processes for square-shaped downpipes, which are crucial components in drainage systems.

Experience suggests that choosing the right square downpipe roll forming machine can make a marked difference in product quality and operational efficiency. Manufacturers who have invested in modern versions of these machines report substantial improvements in production speed and accuracy. These machines are specifically engineered to handle a variety of metal thicknesses and types, ensuring that the end products meet stringent industry standards. Furthermore, the ability to customize and adapt to specific project requirements is a significant advantage, making these machines versatile for different industrial needs.

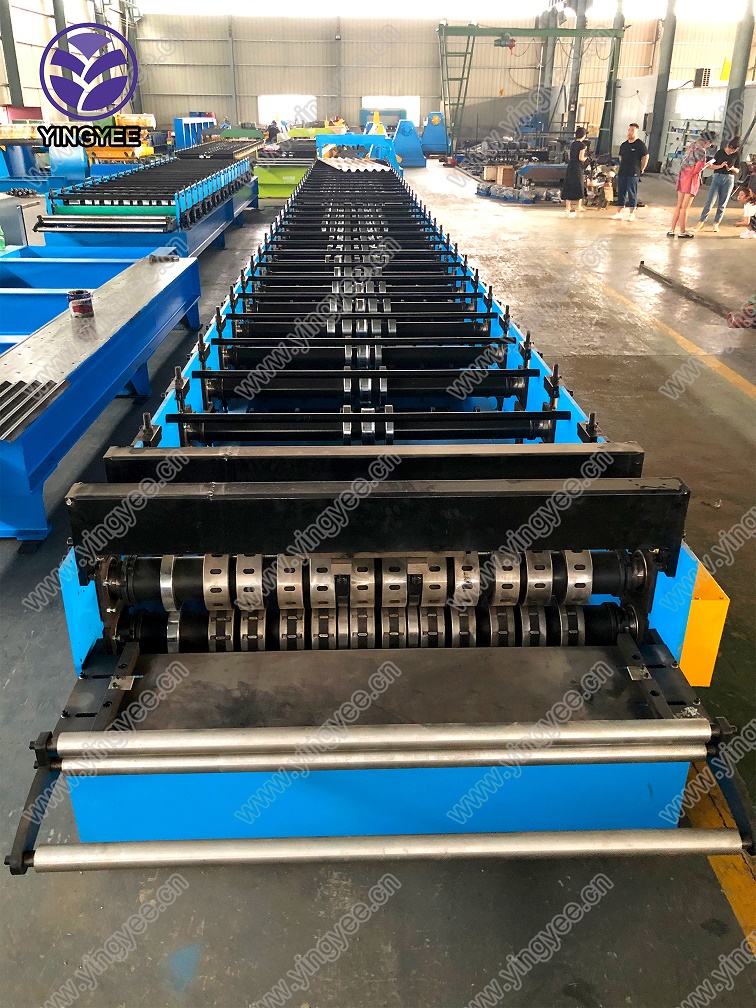

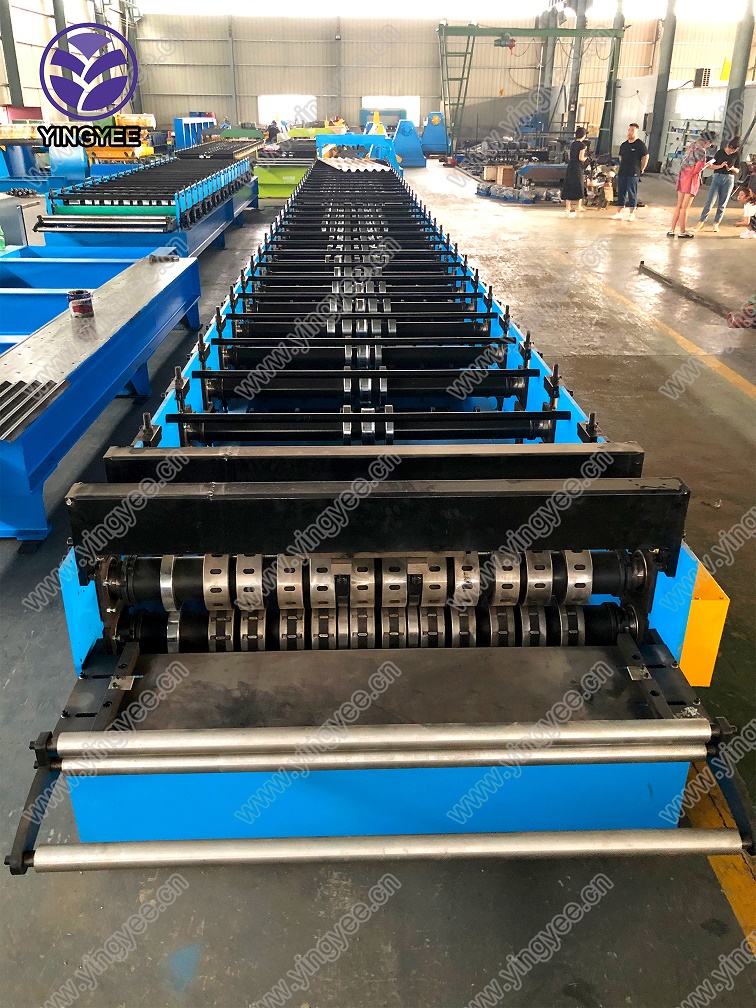

The expertise involved in operating a square downpipe roll forming machine cannot be underestimated. Operators must be trained in handling the complex settings of the machinery to align with production demands accurately. This often requires a deep understanding of the mechanical aspects, including roll configuration, feeding mechanism, and cutting technology. The comprehensive knowledge ensures that the machine operates at optimal performance levels, reducing material waste and minimizing downtime, thus enhancing productivity.

Authoritativeness in the industry comes from manufacturers who are recognized for their innovative designs and technological advancements. Leading brands in square downpipe roll forming machines focus on integrating state-of-the-art technology such as automated controls and advanced monitoring systems. These features not only improve the precision of the formed products but also ensure that the machines are easy to operate, maintain, and diagnose for any potential issues. This high level of technical innovation fosters trust with consumers and heightens the brand's reputation in the market.

square downpipe roll forming machine

Trustworthiness is further cemented by consistent quality assurance practices implemented by manufacturers. Machines undergo rigorous testing procedures to validate their reliability and performance under various operational conditions. Additionally, many manufacturers provide extensive warranties and customer support services, which are crucial for maintaining long-term relationships with buyers, ensuring they feel secure in their investment.

Beyond the technical specifications, the decision to implement a square downpipe roll forming machine should also align with broader business objectives. Companies seeking environmentally sustainable production will find these machines beneficial due to their efficiency in material usage and minimal energy consumption. Furthermore, the reduction in manual intervention and consistent output quality make these machines a financially sound investment, capable of delivering a high return on investment by improving operational metrics such as throughput and quality assurance.

In conclusion, square downpipe roll forming machines distinguish themselves as indispensable assets in the modern manufacturing landscape. The blend of experience, expertise, authoritativeness, and trustworthiness they bring elevates their status beyond mere machinery to become central to strategic planning in production environments. As industry demand for efficient and reliable manufacturing solutions continues to grow, these machines are poised to play an even more critical role, ensuring that manufacturers can meet current and future challenges with confidence and precision. The capabilities these machines offer not only match the needs of today’s manufacturers but also pave the way for advancements in industrial processing technologies.