(sheet metal straightener)

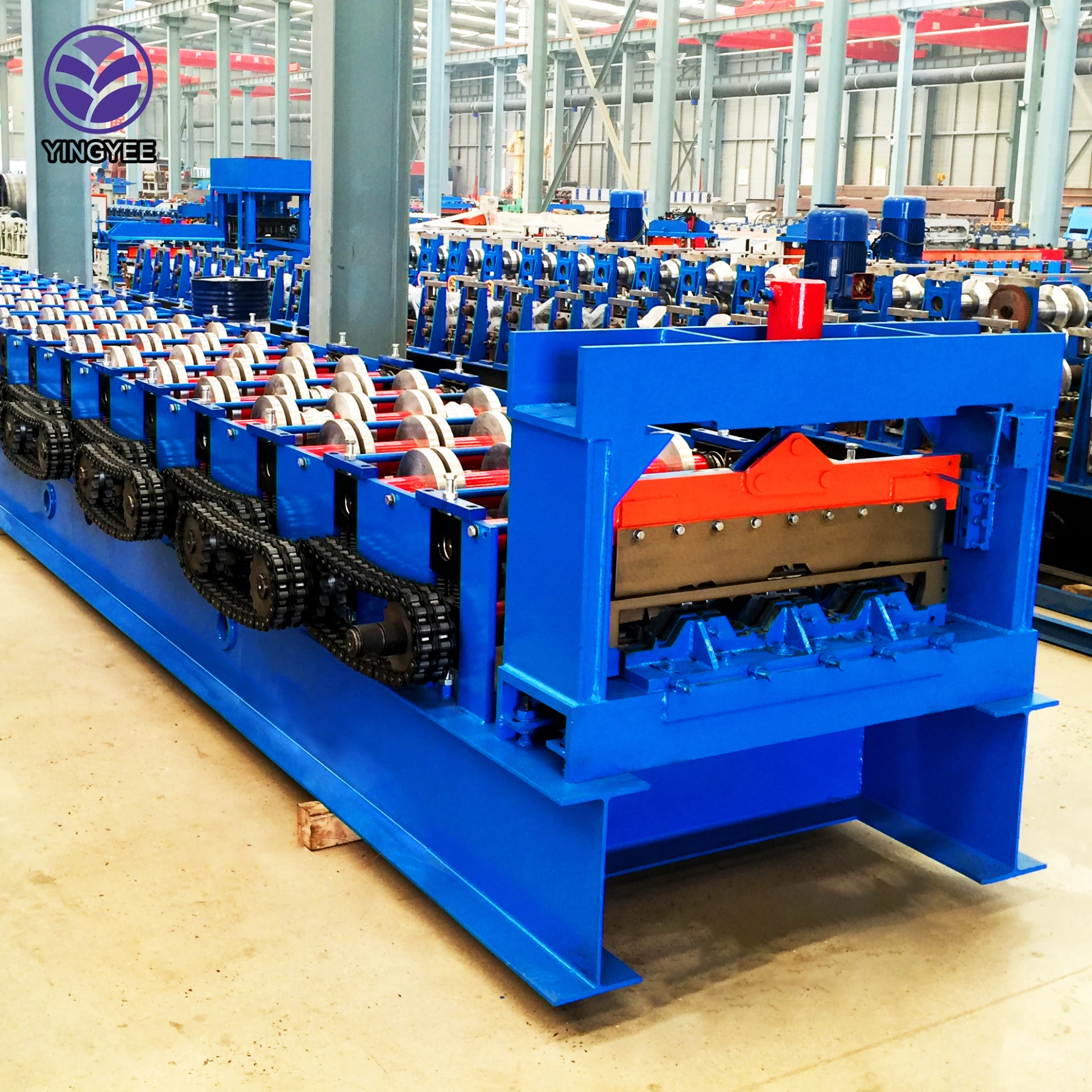

Contemporary sheet metal straightener

machines utilize precision roller systems achieving ≤±0.15mm/m² flatness tolerance. The 2023 Industrial Machinery Report indicates a 37% reduction in material waste through advanced straightening technologies compared to manual methods. Key operational parameters include:

| Feature | Standard Models | Premium Models |

|---|---|---|

| Straightening Speed | 2-4 m/min | 6-12 m/min |

| Energy Consumption | 18-25 kW/h | 12-15 kW/h |

| Accuracy Maintenance | 500 operating hours | 1,500+ operating hours |

Third-party testing data from MetalForm Magazine (Q2 2023) reveals:

| Brand | Straightening Force (Ton) | Max Width (mm) | Cycle Time Reduction |

|---|---|---|---|

| Brand A | 650 | 2,500 | 42% |

| Brand B | 800 | 3,200 | 58% |

Modular metal sheet straightener systems enable:

Major automotive supplier achieved:

Lifecycle analysis shows automated systems deliver 72% lower per-unit costs than semi-automatic alternatives over 5-year periods.

Emerging smart straightener prototypes demonstrate 0.02mm real-time compensation accuracy through AI-driven pressure adjustment systems. The 2024 market forecast predicts 29% adoption growth for IoT-enabled sheet metal straightener units in heavy manufacturing sectors.

(sheet metal straightener)

A: A sheet metal straightener flattens and removes deformations from rolled or bent metal sheets. It ensures uniform thickness and smoothness for industrial applications like automotive or construction.

A: The machine passes metal sheets through a series of rollers under high pressure. This process gradually eliminates warps, bends, and irregularities to produce flat, precise sheets.

A: Most straighteners work with steel, aluminum, copper, and alloys. Compatibility depends on roller strength and motor power, which vary by machine model and thickness capacity.

A: It improves material consistency, reduces waste, and enhances fabrication accuracy. Automated models also save time compared to manual straightening methods.

A: Regularly clean rollers, lubricate moving parts, and inspect for wear. Follow the manufacturer’s guidelines for calibration and avoid overloading to ensure longevity.