In the realm of manufacturing and industrial innovation, the roller shutter door slat machine stands out as a pivotal tool in the production of resilient and efficient shutter systems. A blend of precise engineering and cutting-edge technology, these machines are transforming how businesses and residential entities enhance security and privacy. With a focus on Experience, Expertise, Authoritativeness, and Trustworthiness (EEAT), this article will delve into the multifaceted world of roller shutter door slat machines, exploring the factors that cement their essential role in modern construction and design.

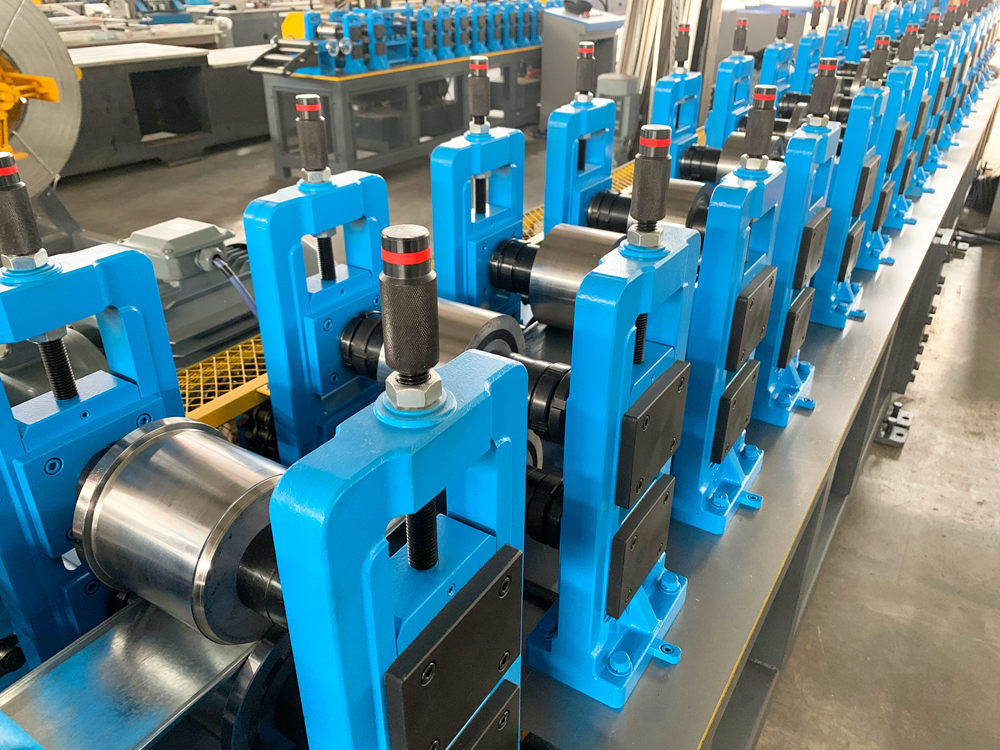

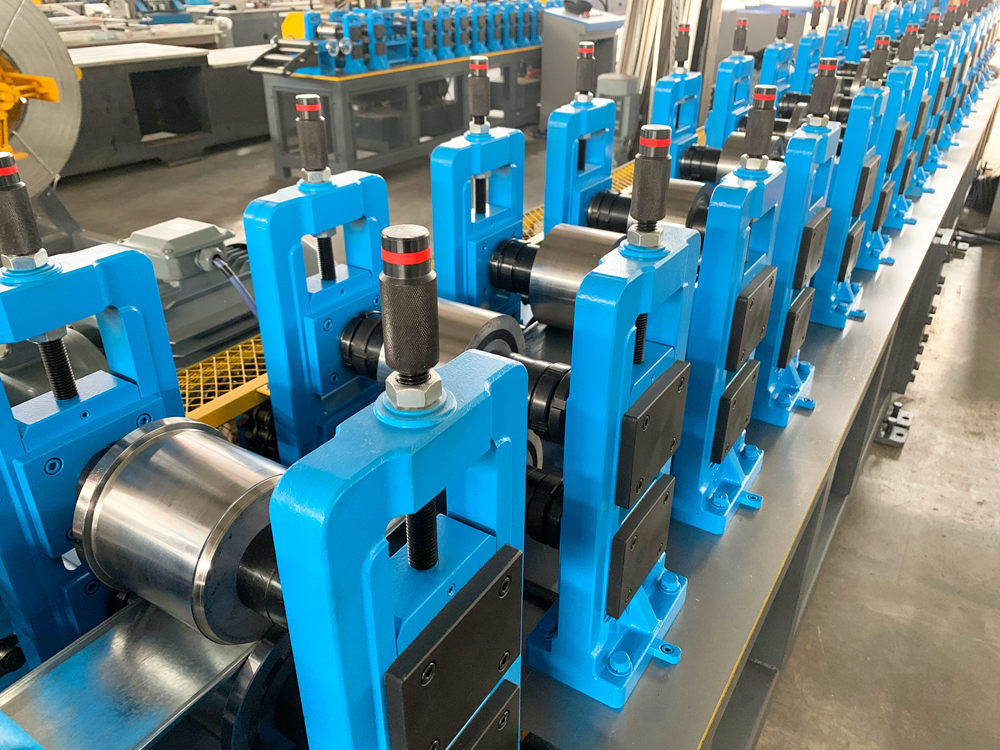

Roller shutter door slat machines are marvels of modern engineering, designed to produce the slats that form the backbone of roller shutters. These machines are not just generating components; they are shaping the future of customizable, durable, and secure entrances. The latest models are engineered to be highly programmable, allowing operators to tailor the specifications of each slat according to client needs. This customization revolutionizes the way shutters fit into the design narratives of homes and commercial properties.

From an expertise standpoint, operating a roller shutter door slat machine demands a comprehensive understanding of both the mechanical system and the end-product's functional requirements. Skilled technicians undergo meticulous training to master the controls and calibrations necessary for optimal performance. They must ensure that each slat produced meets stringent quality criteria, including uniformity, flexibility, and strength. This meticulous attention to detail underscores the personnel expertise needed to maximize the machine's potential and deliver superior products consistently.

Authoritativeness in the domain of roller shutter door slat machines is affirmed by the evolution and refinement of the technology itself. Over the years, advancements have been shaped by feedback from industry professionals and structural engineers, ensuring that the machines meet the burgeoning demands of robust construction standards. The integration of computer-aided design (CAD) and automated quality control systems further enhances their precision and efficiency. These developments position the roller shutter door slat machine as a linchpin in the creation of cutting-edge home and business protection solutions.

roller shutter door slat machine

Trustworthiness is paramount in machinery where safety and security are top priorities. Manufacturers often conduct exhaustive testing to guarantee that every shutter slat produced can withstand climatic challenges and potential security threats. The reliability of these machines is bolstered by rigorous certification processes, adherence to international safety standards, and validation by third-party testing agencies. This commitment to quality assurance provides end-users with confidence in the machine's output, reinforcing its credibility within the industry.

A standout feature of the roller shutter door slat machine is its capacity for high-volume production without compromising on quality. This attribute is critical for large-scale projects where timing and dependability are non-negotiable. Moreover, the machines are being designed to be more energy-efficient, aligning with global sustainability goals by reducing the carbon footprint of the production process. This efficiency not only advances environmental responsibility but also reduces operational costs, offering significant value to businesses.

In conclusion, the roller shutter door slat machine represents a convergence of experience-driven innovation, specialized expertise, authoritative advancements, and unwavering trust. It serves as more than just a production tool; it is a testament to the industry’s commitment to enhancing the safety, functionality, and aesthetic appeal of modern architectural designs. As these machines continue to evolve, they will undoubtedly further solidify their status as indispensable assets in the field of construction and security technology.