When it comes to ensuring road safety, the significance of a road safety barrier cold bending machine cannot be overstated. As demand for superior infrastructure and road safety mechanisms grows, this sophisticated piece of engineering stands at the forefront. From a technical standpoint, these machines exemplify the cutting-edge synthesis of engineering and innovation, and their functionality extends beyond mere metal bending.

A road safety barrier cold bending machine is designed to meet high standards of precision and durability, playing a pivotal role in motorway and urban road safety systems. It facilitates the cold bending of metal beams used in barriers, shaping them to required specifications without compromising their structural integrity. This process is crucial in maintaining the resilience of metal under high-impact scenarios, a common occurrence on busy roads.

Ease of use is one of the strongest points of this machine. Operators require minimal retraining to achieve proficiency due to intuitive controls and automated adjustment systems. These features ensure that even complex bending operations are conducted with minimal human error, leading to increased productivity and enhanced safety barriers.

From the expertise perspective, manufacturers invest heavily in research and development to incorporate the latest technology in their machines. This ensures that the machines not only meet international safety standards but also excel in energy efficiency and environmental compatibility. The precision offered by these machines allows the fabrication of uniform barrier components, which is critical for the systematic installation and overall effectiveness of road safety measures.

Providing a reliable source of expertly crafted safety barriers, cold bending machines embody the principles of authoritativeness and trustworthiness the industry demands. Leading manufacturers often undergo rigorous certifications and compliance checks to validate their offerings. Users of these machines often report enhanced longevity of barriers and a noticeable reduction in maintenance costs, underlining the machine's long-term reliability and cost-effectiveness.

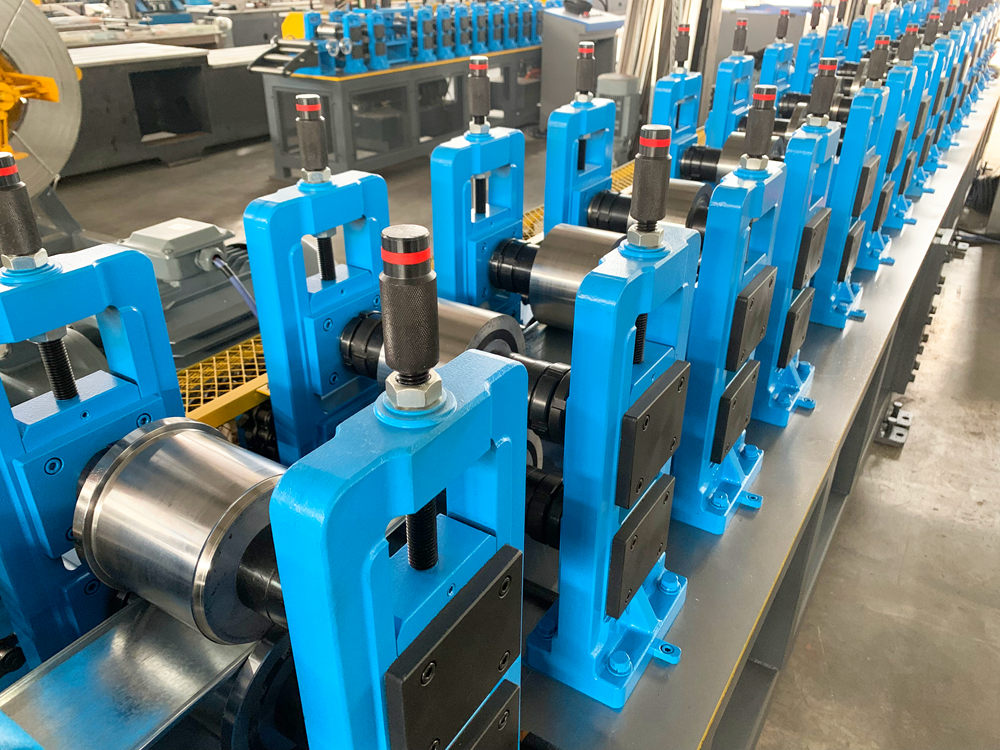

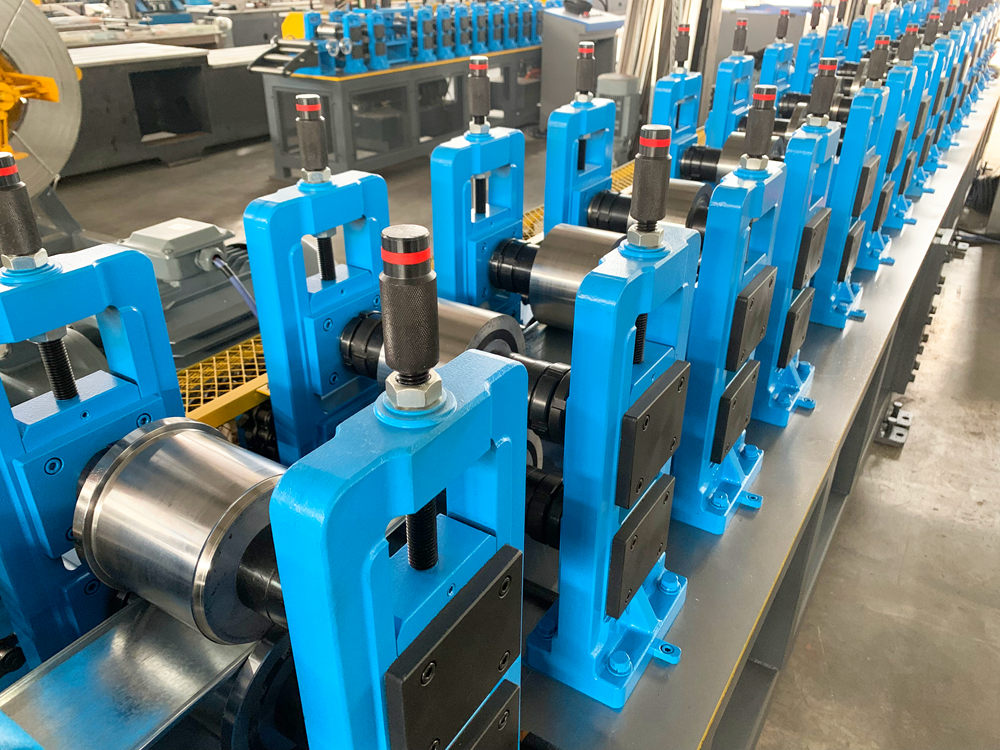

road safety barrier cold bending machine

The construction materials used in these machines typically include high-grade steel and components built to withstand constant use without deterioration. This robustness translates into reduced downtime and lower replacement costs, further substantiating the machine's efficiency and reliability. Such qualities resonate particularly well in sectors where operational continuity is paramount, such as in road construction and maintenance operations.

In terms of experience, numerous case studies underscore the transformative impact of these machines on the efficiency of road safety barrier projects. For instance, a notable highway expansion project that employed advanced cold bending technology observed a 30% reduction in installation time and a similar decrease in project costs. This case highlights not only the operational and financial benefits but also the enhanced safety outcomes ultimately achieved.

Moreover, the flexibility offered by modern road safety barrier cold bending machines allows for customization according to specific regional safety standards and individual project requirements. This adaptability is an essential factor for contractors working across diverse geographies, ensuring that safety barriers meet local regulations without compromising on quality.

Advancements in automation continue to refine the precision of cold bending processes, reducing the manual effort required and permitting real-time adjustments to meet precise engineering demands. These technological strides further affirm the machine's position as a vital element in infrastructure development while adhering to the highest safety and productivity standards.

In conclusion, the road safety barrier cold bending machine represents not just a significant technological advancement, but an essential tool for achieving greater road safety and efficiency. Its role in shaping durable and reliable safety barriers is unmatched, establishing itself as a cornerstone of modern infrastructure projects worldwide. This, combined with its ease of use, authoritative stance in the market, and undeniable trustworthiness, ensures it remains an indispensable asset in enhancing road safety for future generations.