The evolution of construction techniques has been phenomenal over the years, and one machine that epitomizes this transformation is the purlin stud machine. As a cornerstone of the modern construction sector, the purlin stud machine has redefined the efficiency and precision of building processes. Designed to create purlin studs vital in roofing structures, this machine ensures buildings not only stand the test of time but also align with contemporary architectural styles and quality standards.

Engineered with cutting-edge technology, the purlin stud machine offers unparalleled operational efficiency. It operates through an intricate system that shapes metal sheets into strong, durable purlins used as secondary framing in structures. These purlins provide essential support to roofs,

embracing both strength and lightweight properties. This dual advantage is crucial for builders aiming for constructions that maintain structural integrity while reducing the weight load on the overall building framework.

Experience with the purlin stud machine reveals its potential to revolutionize workflow dynamics within manufacturing facilities. One of the most significant benefits is its automation capability. Operators can achieve precision with minimal manual input, thus drastically reducing human error. This automation not only accelerates production but also guarantees consistency in the quality of manufactured purlins, conforming to stringent industry standards.

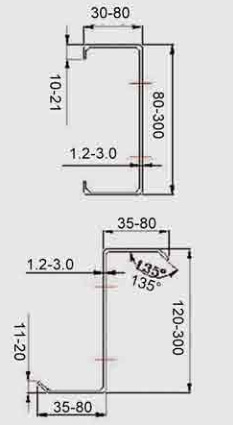

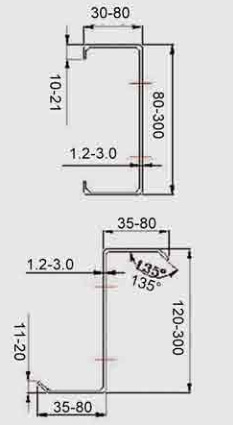

The expertise embedded in a purlin stud machine lies in its advanced software and hardware integrations. Using programmable logic controllers (PLCs), the machine can be adjusted to shape various sizes and forms of purlin to meet different architectural requirements. The robustness of this technology caters to diverse industry needs, from the lofty demands of skyscraper constructions to the more modest needs of residential projects. Its ability to produce variable lengths and thicknesses of purlin makes it an indispensable tool in a builder's arsenal, offering customized solutions that are both cost-effective and efficient.

purlin stud machine

From an authoritative perspective, the purlin stud machine represents a leap forward in modular and sustainable construction practices. Industry experts tout its reliability, having seen first-hand its contribution to reducing waste through precise material usage and its role in promoting green building initiatives. Additionally, manufacturers of the purlin stud machine often provide detailed certifications and compliance documents that adhere to international construction standards, such as ISO and AISI, which underscore its credibility and readiness for global use.

The trustworthiness of purlin stud machines is further underlined by the extensive testing protocols they undergo before being deemed market-ready. Manufacturers invest in rigorous quality assurance processes to ensure each machine meets designated safety and performance benchmarks. Consequently, contractors and builders can trust that the machine will deliver consistent results, optimizing both time and resources on-site and offsite.

In conclusion, the purlin stud machine stands as a testament to how technology can enhance traditional construction methodologies, driving advancements that benefit architects, engineers, and construction firms alike. With its blend of precision, efficiency, and adaptability, this machine not only supports the fabrication of purlins but also empowers the industry towards innovation and excellence. As more construction professionals recognize the benefits brought by these machines, the future of building design continues to look increasingly promising and sustainable.