Understanding the Purlin Roll Forming Machine for C/Z Profiles (100-300mm)

The construction industry has seen significant innovations over the years, with advancements in machinery that enhance productivity while ensuring high-quality outputs. One such innovation is the purlin roll forming machine, specifically designed for producing C and Z purlins ranging from 100mm to 300mm. Understanding how this machine operates can give insights into its value in modern construction processes.

What is a Purlin and its Function?

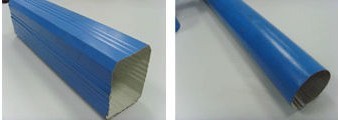

Purlins are horizontal structural members that support the roof decking or sheeting in a building. They act as a bridge between the walls, providing stability and strength, particularly in metal buildings. The C and Z purlins are commonly used due to their versatility and strength. The choice between C and Z profiles often depends on the specific structural requirements of a project, with each having unique advantages.

The Role of Roll Forming Machines

Roll forming is a continuous bending process in which metal sheets are passed through a series of rollers to achieve desired shapes and sizes. In the case of purlins, the roll forming machine creates precise C and Z profiles efficiently. The machine operates by feeding a flat steel sheet through a series of rollers, which progressively shape the metal into the desired profile.

Features of the C/Z Purlin Roll Forming Machine (100-300mm)

1. Adjustability The purlin roll forming machine is designed to produce varied sizes of C and Z profiles, specifically within the 100–300mm range. This versatility is crucial for contractors who require customized solutions based on different building specifications.

2. Automation and Efficiency Many modern roll forming machines come equipped with automated controls, allowing for faster production speeds and reduced labor costs. This automation not only enhances efficiency but also minimizes the risk of human error in the manufacturing process.

3. Material Compatibility These machines can work with a variety of materials, including galvanized steel, aluminum, and other alloys. This flexibility allows builders to choose materials that best suit their project's requirements while also adhering to local building codes.

4. Precision Engineering Roll forming machines are designed to deliver precision in every piece produced. The accuracy of dimensions and alignment is vital for the structural integrity of purlins and ultimately the entire building.

5. Low Waste Production Unlike traditional cutting methods, roll forming produces less scrap material, making it a cost-effective and environmentally friendly option. The continuous nature of the process allows for better utilization of raw materials, reducing the overall costs of production.

Applications of C/Z Purlin Roll Forming

The output from a C/Z purlin roll forming machine is widely used across various applications in the construction sector. These purlins are an essential component in pre-engineered buildings, industrial facilities, agricultural structures, and warehouses. Their strength and adaptability make them suitable for both commercial and residential projects.

Conclusion

The purlin roll forming machine for C/Z profiles ranging from 100 to 300mm represents a significant advancement in manufacturing technology within the construction industry. The benefits of efficiency, precision, and versatility offered by these machines contribute positively to project timelines and budgets. As the demand for quality construction increases, the importance of such innovations cannot be overstated. Businesses looking to stay competitive must consider the integration of modern machinery like the purlin roll forming machine into their manufacturing processes. With continued advancements in technology, the future of roll forming and the use of C and Z purlins in construction looks promising.