Navigating the dynamic landscape of construction, especially in roofing solutions, demands attention to cutting-edge technologies that enhance efficiency, durability, and aesthetic appeal. One game-changing innovation that construction professionals increasingly rely on is the PPGI glazed tile roofing making machine. This sophisticated piece of machinery stands out in the realm of modern roofing for its ability to seamlessly integrate advanced manufacturing with creative design needs, offering unparalleled utility and value.

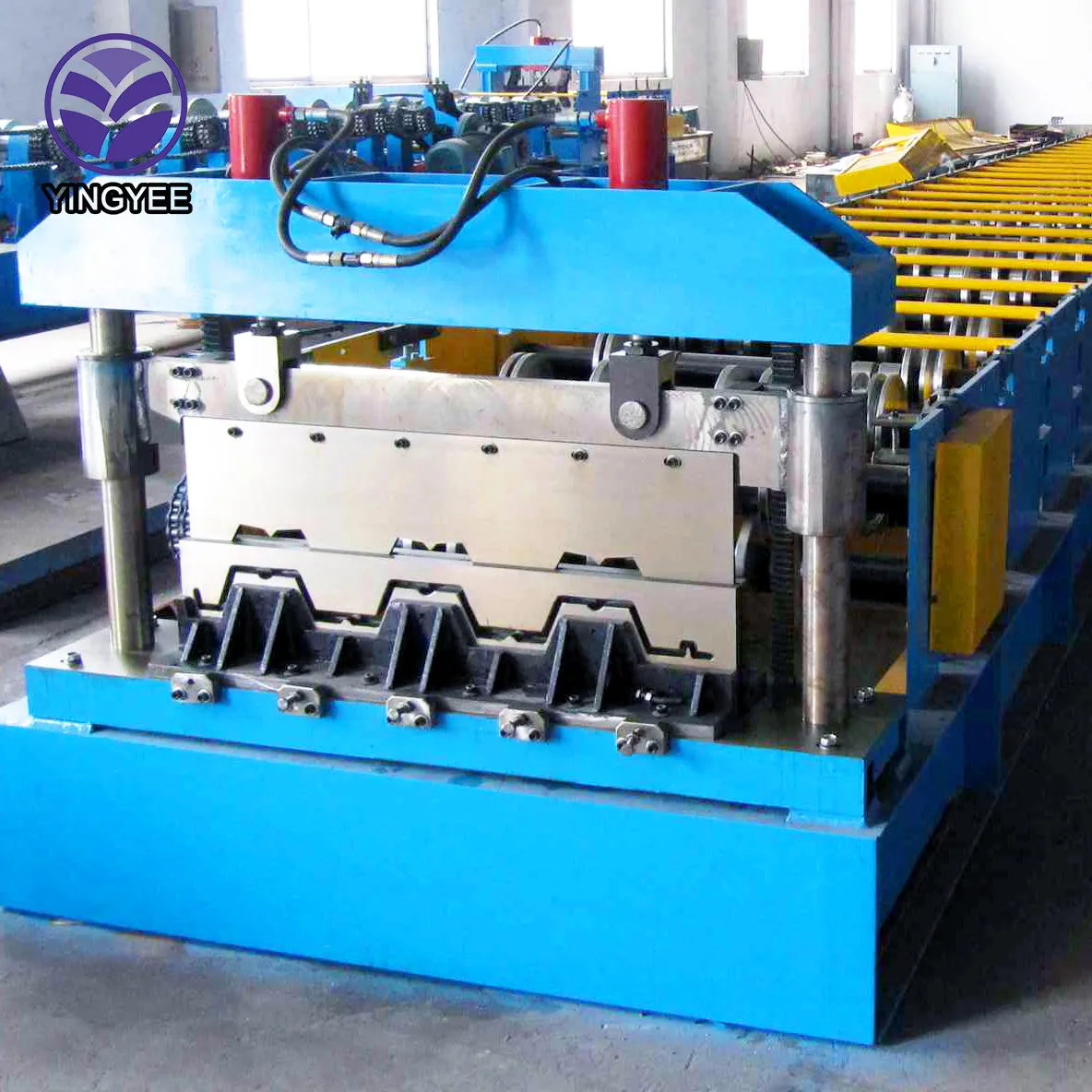

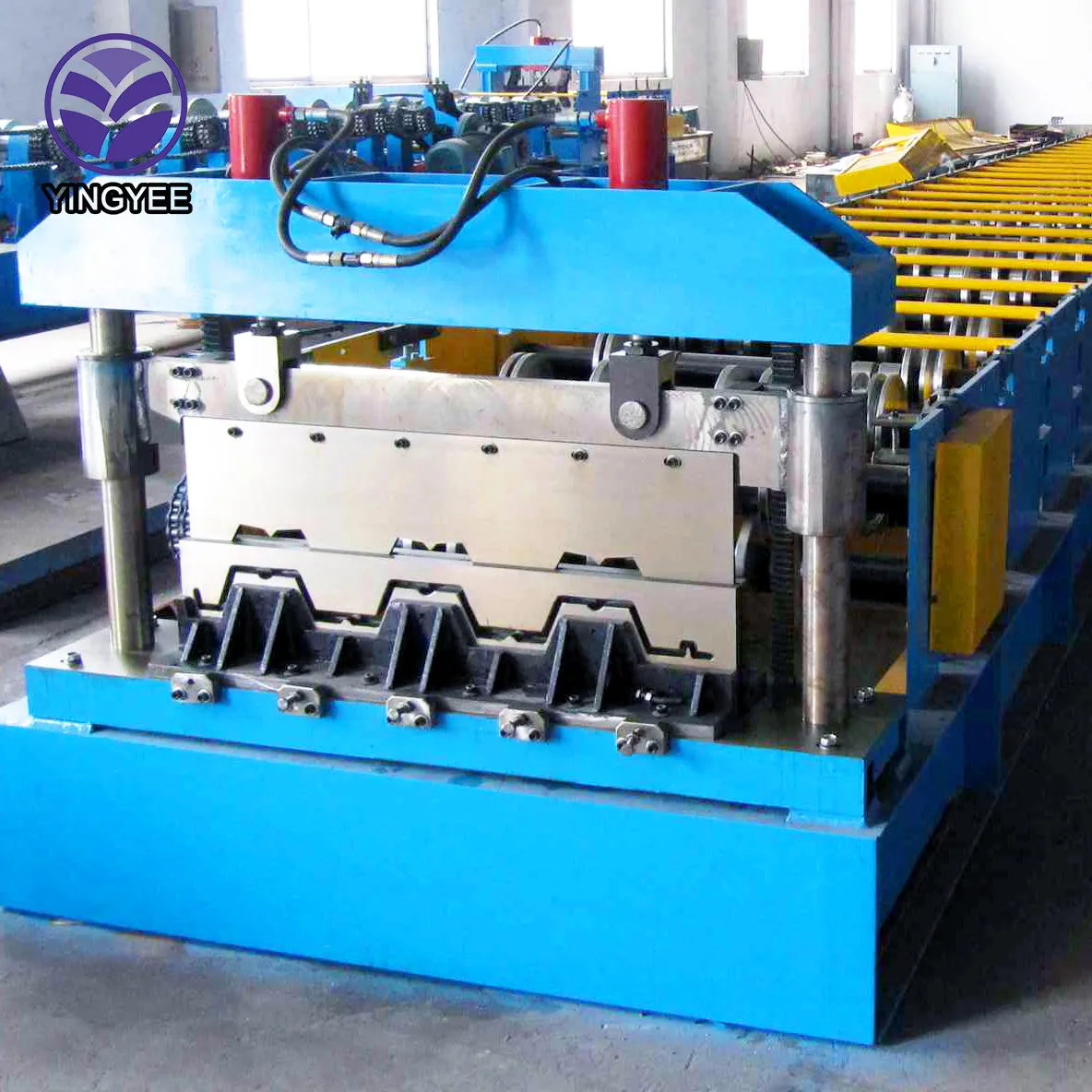

Professionals in the roofing industry will appreciate the tangible benefits of integrating a PPGI glazed tile roofing making machine into their production process. At its core, this machine uses Prepainted Galvanized Iron (PPGI), a material known for its durability, resistance to corrosion, and ability to maintain vibrant colors over time. The process begins with feeding the PPGI sheets into the machine, which are then meticulously shaped and cut into glazed tiles. This process ensures uniformity and precision, vital for producing high-quality roofing components that stand the test of time.

Expertise in handling a PPGI glazed tile roofing making machine underscores significant professional competence. The machinery is equipped with state-of-the-art technology, including automated controls that ensure precision in operation. Operators skilled in leveraging these tools can optimize the production line, reduce material wastage, and significantly cut down on lead times to meet tight project deadlines. These enhancements in the manufacturing process directly benefit contractors who seek reliable, aesthetically pleasing, and cost-effective roofing solutions for their clients.

Authoritative voices in the field of construction technology often emphasize the importance of adopting machinery that not only meets current needs but is adaptable for future trends. The PPGI glazed tile roofing making machine exemplifies this by supporting a wide range of design specifications and customizations. Whether it's emulating the classic appeal of ceramic tiles or exploring modern interpretations with unique color palettes and textures, the machine offers versatility that allows designers and architects freedom in creativity while retaining structural integrity.

ppgi glazed tile roofing making machine

End-user trust in products manufactured using the PPGI glazed tile roofing making machine is underpinned by rigorous quality assurances. Manufacturers employing these machines often adhere to international standards and certification processes that guarantee the performance and safety of the roofing tiles produced. For builders and homeowners alike, this assurance is paramount, as it speaks directly to the longevity and resilience of the roofing, crucial considerations in sectors burdened by environmental impacts and fluctuating climates.

Furthermore, sustainability is a growing trend within the construction industry, and utilizing machines that prioritize efficiency aligns with this direction. PPGI is inherently more environmentally friendly due to its recyclability and the ability to employ less energy-intensive processes during production. Companies that invest in such technology invariably bolster their reputation as environmentally-conscious and technically adept pioneers.

In conclusion, the PPGI glazed tile roofing making machine represents a leap forward in the production of roofing materials that embody the ideal balance of form and function. Its incorporation into manufacturing not only uplifts the standards of product quality but also streamlines operations, highlighting the significant strides made toward advanced, sustainable roofing solutions. For professionals keen on remaining competitive and forward-thinking in their approach, embracing such technology could provide a pivotal edge in an ever-evolving industry landscape.