The Advancements in PPGI Glazed Tile Roofing Making Machines

In the realm of modern construction, roofing materials play a pivotal role in the durability, aesthetic appeal, and overall performance of buildings. PPGI (Pre-Painted Galvanized Iron) glazed tile roofing has emerged as a highly sought-after choice for its exceptional qualities. The technology behind the manufacturing of PPGI glazed tile roofing has also advanced, leading to the development of specialized machines that streamline the production process.

The Advancements in PPGI Glazed Tile Roofing Making Machines

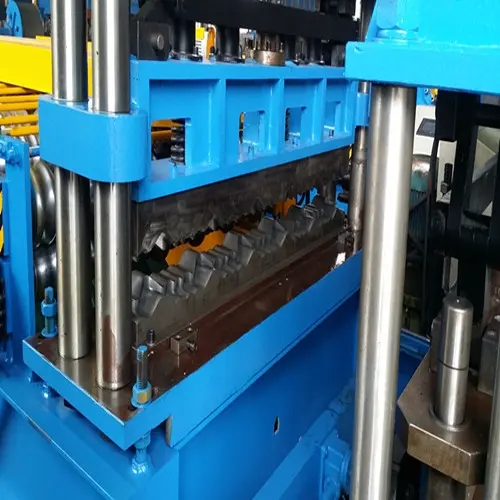

The PPGI glazed tile roofing making machine is a sophisticated piece of equipment designed to automate and optimize the production process. These machines are equipped with advanced technology that allows for the rapid transformation of raw materials into finished roofing tiles. They typically comprise various components such as decoilers, roll forming systems, cutting tools, and shearing devices, all working together in harmony.

One of the primary advantages of using specialized machines for PPGI glazed tile production is the significant reduction in labor costs and time. Traditional methods of tile manufacturing can be labor-intensive and time-consuming, but with modern machinery, the process is accelerated. High-speed roll forming machines can produce tiles at a remarkable rate, ensuring that production demands are met without compromising quality. Automated systems also minimize human error, resulting in consistent and reliable output.

Moreover, these roofing making machines are designed with flexibility in mind. Manufacturers can easily adjust parameters to create different tile shapes, sizes, and colors, catering to diverse consumer preferences and market demands. This adaptability is crucial in today’s competitive construction environment, where customization is highly valued. Additionally, advancements in technology have enhanced the precision of these machines, ensuring that every tile produced meets stringent quality standards.

Energy efficiency is another significant aspect of modern PPGI glazed tile roofing making machines. Many new models are designed to operate with reduced energy consumption while maintaining high production speeds. This not only saves costs for manufacturers but also aligns with the growing emphasis on sustainability in construction practices. By investing in energy-efficient machinery, producers can reduce their carbon footprint and contribute to more environmentally friendly building solutions.

In conclusion, the evolution of PPGI glazed tile roofing making machines has revolutionized the roofing industry. These advanced machines facilitate high-quality production while reducing labor costs and operational time. Their flexibility and energy efficiency make them an appealing choice for manufacturers aiming to meet the increasing demand for stylish and durable roofing solutions. As the construction sector continues to grow and evolve, the significance of these machines will only increase, paving the way for innovation and sustainability in roofing materials. Through continuous advancements in technology, the future of PPGI glazed tile roofing manufacturing looks promising, ensuring that builders have the tools they need to create lasting structures.