Understanding Rebar Thread Rolling Machines A Comprehensive Overview

Rebar thread rolling machines are essential tools in the construction industry, designed to enhance the efficiency and quality of rebar processing. These machines allow for the development of threaded ends on rebars, which are vital for creating strong and secure connections in reinforced concrete structures. The use of rebar thread rolling machines has become increasingly popular due to their ability to improve the mechanical properties and performance of rebar in various applications.

The Importance of Threaded Rebar

Rebar, or reinforcing bar, is a steel bar used to reinforce concrete in structures such as buildings, bridges, and roads. When the ends of rebars are threaded, they can be easily connected to each other or to fixtures, creating a strong mechanical bond. Threading also allows for the use of couplers—mechanical devices that can join two pieces of rebar without the need for welding. This connection not only improves the structural integrity of the project but also allows for easier handling and installation.

How Rebar Thread Rolling Machines Work

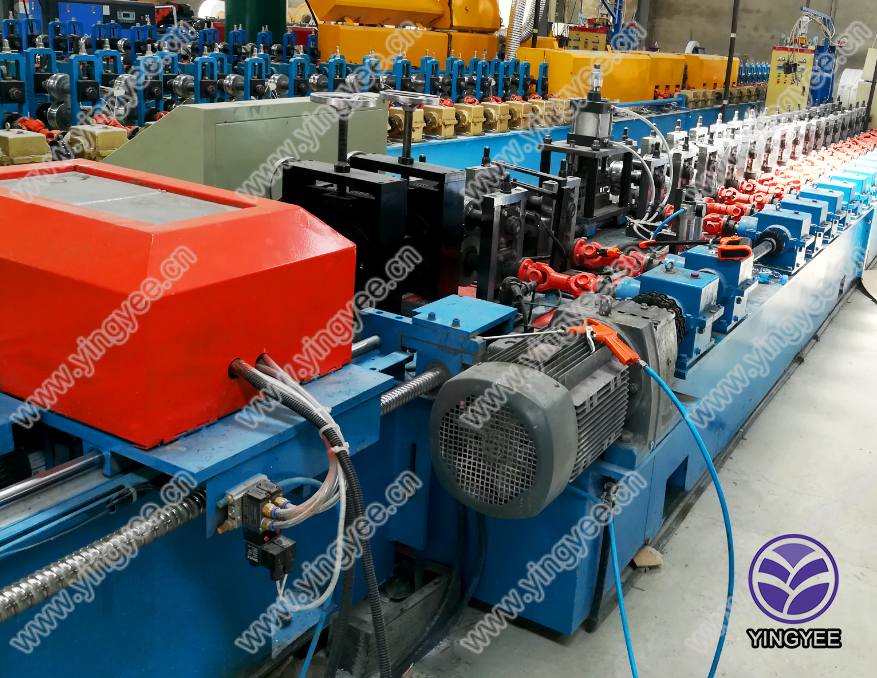

Rebar thread rolling machines operate using a process known as thread rolling. This cold working technique involves passing the rebar through a series of rollers that form threads along its surface. The process is advantageous because it enhances the mechanical properties of the metal by introducing strain hardening, which increases tensile strength and ductility while eliminating the need for heating or melting the material.

Modern rebar thread rolling machines come equipped with advanced technology that allows for precise control over the threading process

. Automatic and semi-automatic versions are available, providing flexibility depending on the needs of the operation. These machines can handle various rebar diameters and configurations, making them versatile tools in any construction-related workshop.

Advantages of Using Rebar Thread Rolling Machines

1. Increased Efficiency Traditional methods of threading rebar, such as cutting or welding, can be time-consuming and labor-intensive. Rebar thread rolling machines drastically reduce the time required to produce threaded bars, enabling faster project completion.

2. Improved Quality The precision of thread rolling machines ensures consistent thread profiles and dimensions, which contribute to reliable connections between rebars and couplers. The cold working nature of the process enhances the overall strength of the rebar.

3. Cost-Effectiveness By streamlining the threading process, these machines reduce labor costs while increasing productivity. The durability of the threaded joints also minimizes the need for maintenance and repairs, offering long-term savings for contractors.

4. Reduced Material Waste Unlike traditional threading methods that may produce scrap metal, rebar thread rolling machines maximize material usage. This not only benefits project budgets but also supports sustainable practices in construction.

Conclusion

As the construction industry evolves, so does the technology utilized in rebar processing. Rebar thread rolling machines represent a significant advancement that contributes to building stronger, safer, and more efficient structures. By embracing this technology, contractors can enhance their operations, improve the quality of their work, and ultimately deliver better results in a competitive marketplace. With ongoing innovations, the future of rebar processing looks promising, paving the way for more reliable construction practices worldwide.