Choosing the right metal stud and track roll forming machine is crucial for manufacturers in the construction industry. As experts in machinery and consumer needs, the selection process often involves understanding the nuances of technology, adaptability to project requirements, and assessing the efficiency of operation—all of which reflect in production costs and output quality.

A metal stud and track roll forming machine is a pivotal tool for producing steel framing components such as studs, joists, and tracks used in building applications. For professionals in construction, especially those focused on prefabricated building structures, it is imperative to opt for a machine that not only provides precision but excels in operational reliability.

One of the first things to examine when considering a machine is its operational efficiency. The versatility of roll forming machines plays a significant role—machines capable of producing different profiles without the need for lengthy adjustments or tool changes can save substantial time and reduce labor costs. Automation, therefore, becomes a key factor. Machines equipped with advanced programmable logic controls (PLCs) can offer rapid setup changes and ensure consistency in production, thereby enhancing the machine's overall productivity.

Durability and maintenance are equally important considerations. Roll forming machines must withstand the demands of high-volume production. Choosing machines from manufacturers known for their robust build quality and durable components can minimize downtimes. In addition, access to maintenance services from the supplier is crucial. Regular maintenance by a qualified technician can prolong the lifespan of a machine and maintain its production efficiency.

One cannot ignore the technological advancements proliferating within the industry. Modern machines are often integrated with real-time monitoring systems that can track maintenance needs and predict failures. This predictive maintenance capability allows manufacturers to address potential issues before they disrupt the production line, thus ensuring uninterrupted operations. These systems also contribute to safety, as automated alerts can prevent accidents caused by mechanical failure.

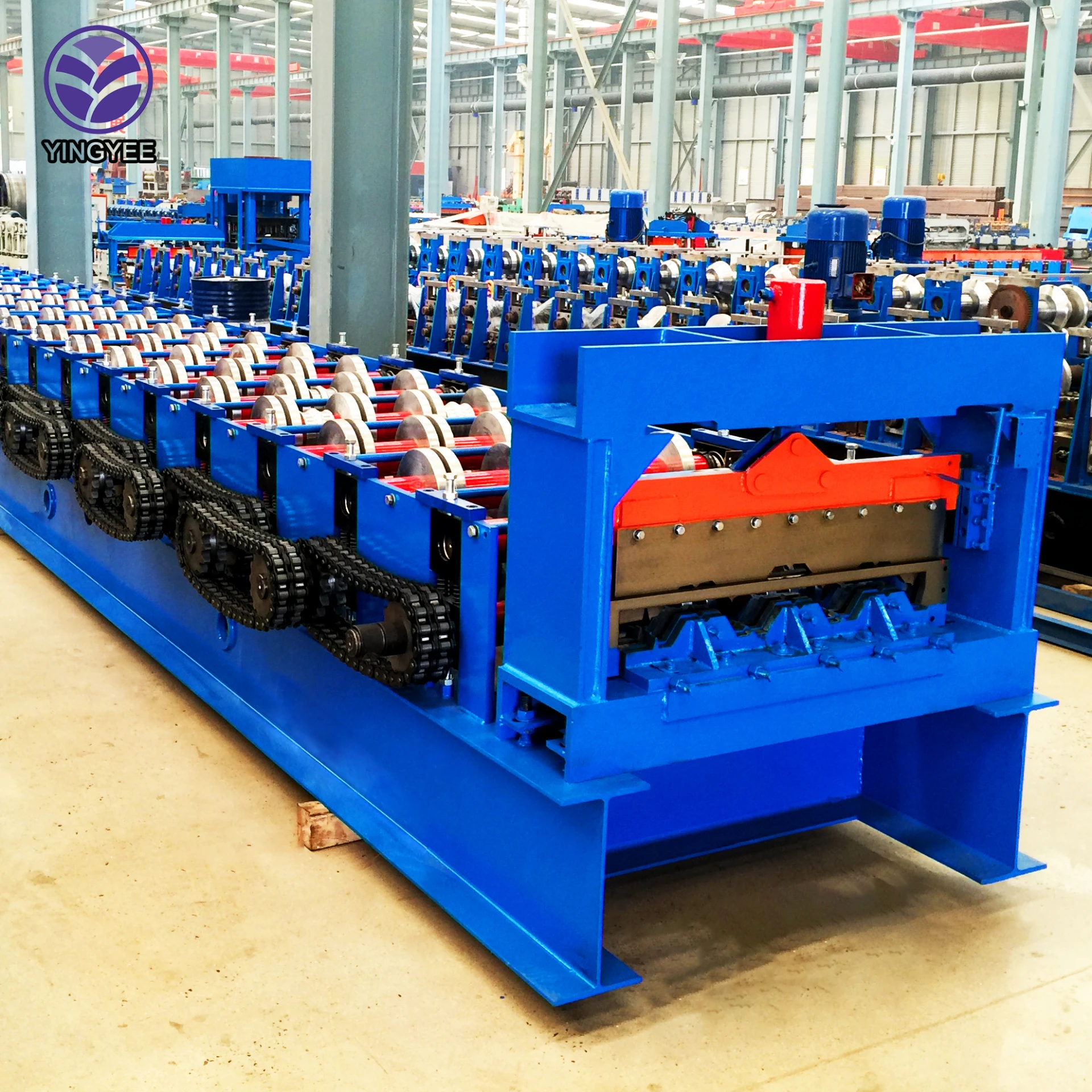

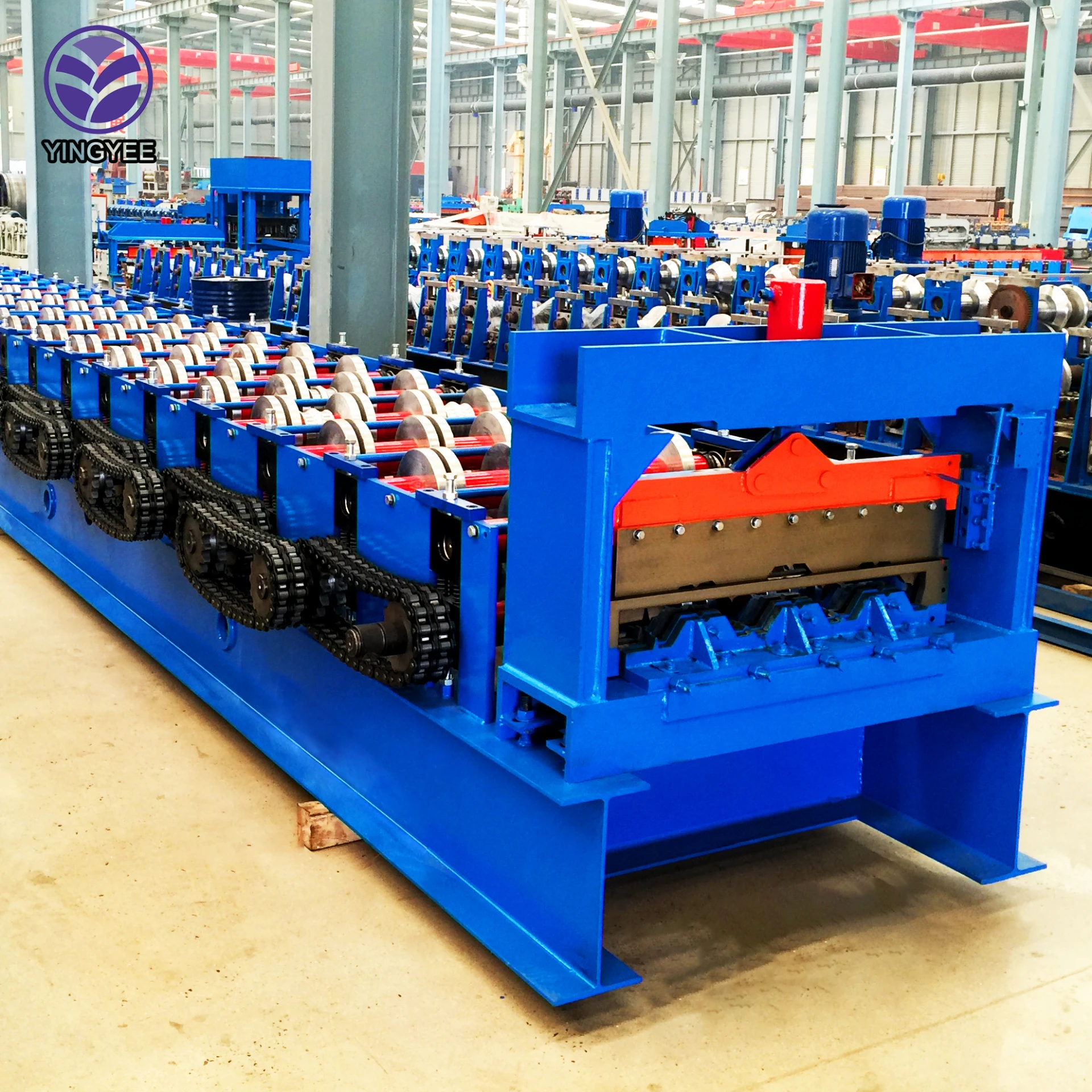

metal stud and track roll forming machine

Quality control is another critical aspect that underscores the superiority of certain roll forming machines over others. The accuracy in dimensions and structural integrity of the finished products are non-negotiable, especially when these components are used in structural applications. Machines with precise control over roll pressure and forming speed are able to maintain tight tolerances that meet or exceed industry standards, thereby assuring the quality of the products manufactured.

Energy efficiency is also a growing concern for companies looking to minimize their environmental footprint and cut costs. Many modern roll forming machines are designed to be energy-efficient, consuming less power without compromising output efficiency. This efficiency not only reduces operational costs but also aligns with global shifts towards sustainable manufacturing practices.

Furthermore, the customization potential of roll forming machines is a compelling feature for manufacturers. Some advanced models allow for customization right down to the smallest detail, enabling the production of specific profiles tailored to unique building requirements. This adaptability often proves beneficial for niche markets where specialized designs are in high demand.

Selecting the appropriate metal stud and track roll forming machine not only depends on the machine’s technical specifications and capabilities but also on the support and training provided by the manufacturer. A reliable supplier should offer comprehensive training programs and detailed manuals to ensure that operators can use the machines effectively and safely. Long-term support arrangements also contribute significantly to building a strong partnership, fostering trust, and ensuring that companies can rely on continuous technical support when required.

By investing in a tailored machine that balances technological innovation with operational practicality, manufacturers position themselves to achieve greater efficiency and maintain competitiveness in the rapidly-evolving construction industry landscape. As the industry moves forward, those who remain informed and make strategic investments in advanced machinery will likely secure a substantial advantage over their peers.