The Importance of Metal Storage Racks and the Role of Upright Pillar Roll Forming Machines

In the ever-evolving landscape of industrial storage solutions, metal storage racks have emerged as essential components in warehouses, retail spaces, and various manufacturing environments. These racks provide a sturdy framework for organizing and storing a wide array of items, from heavy machinery to lightweight goods. The demand for efficient and reliable storage solutions has led to innovations in production methods, and one significant advancement is the upright pillar roll forming machine.

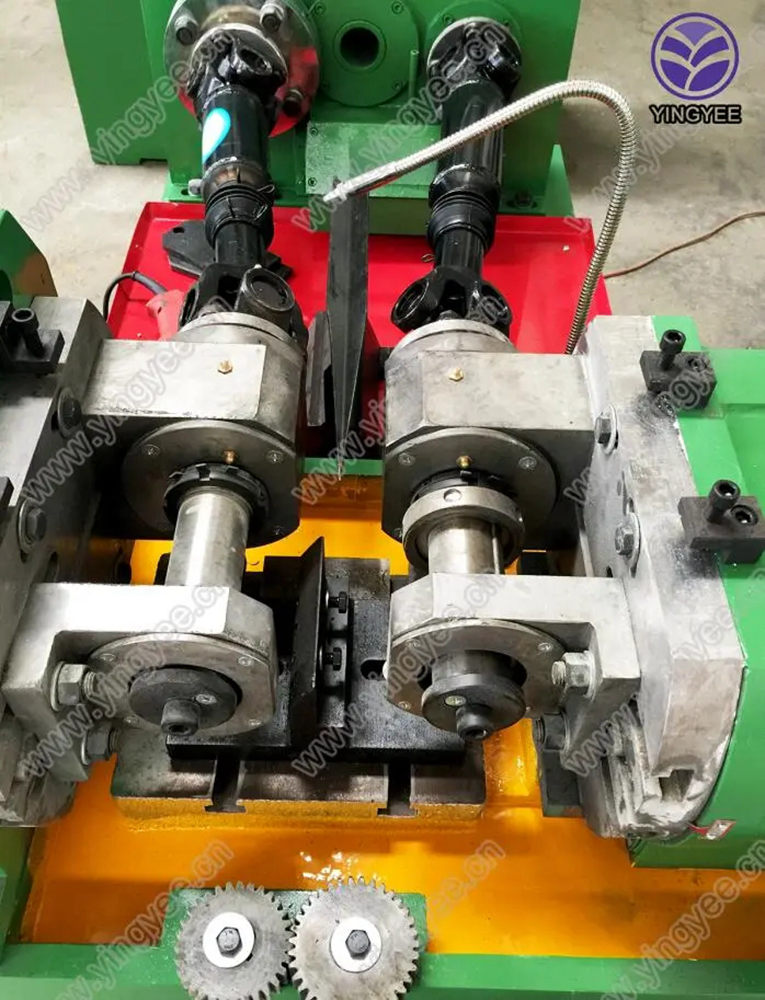

Upright pillar roll forming machines are specialized equipment designed to manufacture the vertical components of metal storage racks, known as uprights. These machines utilize a continuous process to transform flat metal sheets into precisely shaped pillars that can support substantial weight and withstand the rigors of industrial use. The process involves feeding metal sheets through a sequence of rollers that gradually shape the metal into the desired profile. The precision of the roll forming process results in uniformity and strength, qualities that are crucial for the longevity and reliability of metal storage racks.

One of the key advantages of using upright pillar roll forming machines is the ability to customize the dimensions and design of the uprights. Different applications may require specific sizes, load capacities, and configurations to maximize efficiency. Manufacturers can adjust the settings on the roll forming machine to produce uprights that meet exact specifications, reducing waste and ensuring a perfect fit for any shelving system. This level of customization is particularly beneficial for businesses that need adaptable shelving solutions to accommodate changing inventory levels.

Furthermore, the use of roll forming technology in upright pillar production is not only about efficiency but also about sustainability. The process generates minimal scrap material, as the metal sheet is utilized to its fullest potential. This attribute aligns with the growing emphasis on eco-friendly manufacturing practices, allowing businesses to reduce their environmental footprint while maintaining high production standards.

Additionally, metal storage racks produced with precision roll-formed uprights are designed to promote safety in the workplace. The robust construction minimizes the risk of collapse under heavy loads, which is critical for preventing accidents and injuries in storage environments. When adequately designed and installed, these racks can also improve the overall workflow, allowing employees to access stored goods quickly and safely.

In conclusion, metal storage racks and upright pillar roll forming machines play a crucial role in modern industrial environments. The ability to create strong, customized uprights efficiently revolutionizes how businesses approach storage solutions. As industries continue to grow and evolve, the importance of reliable and well-engineered storage systems will only increase, making the innovation behind upright pillar roll forming machines a vital component in the future of warehousing and storage solutions. The marriage of engineering precision, customization, and sustainability not only meets the current demands but also paves the way for future advancements in the field.