The Evolution and Benefits of Metal Rolling Door Cold Forming Machines

In the fast-evolving landscape of metalworking technology, the metal rolling door cold forming machine has emerged as a vital tool in the manufacturing sector. This machinery specializes in producing high-quality metal rolling doors, which are extensively used in various commercial and industrial applications. With the rise of demand for efficient and durable construction materials, cold forming machines have become increasingly relevant. This article will delve into the workings, advantages, and applications of metal rolling door cold forming machines.

Understanding Cold Forming Technology

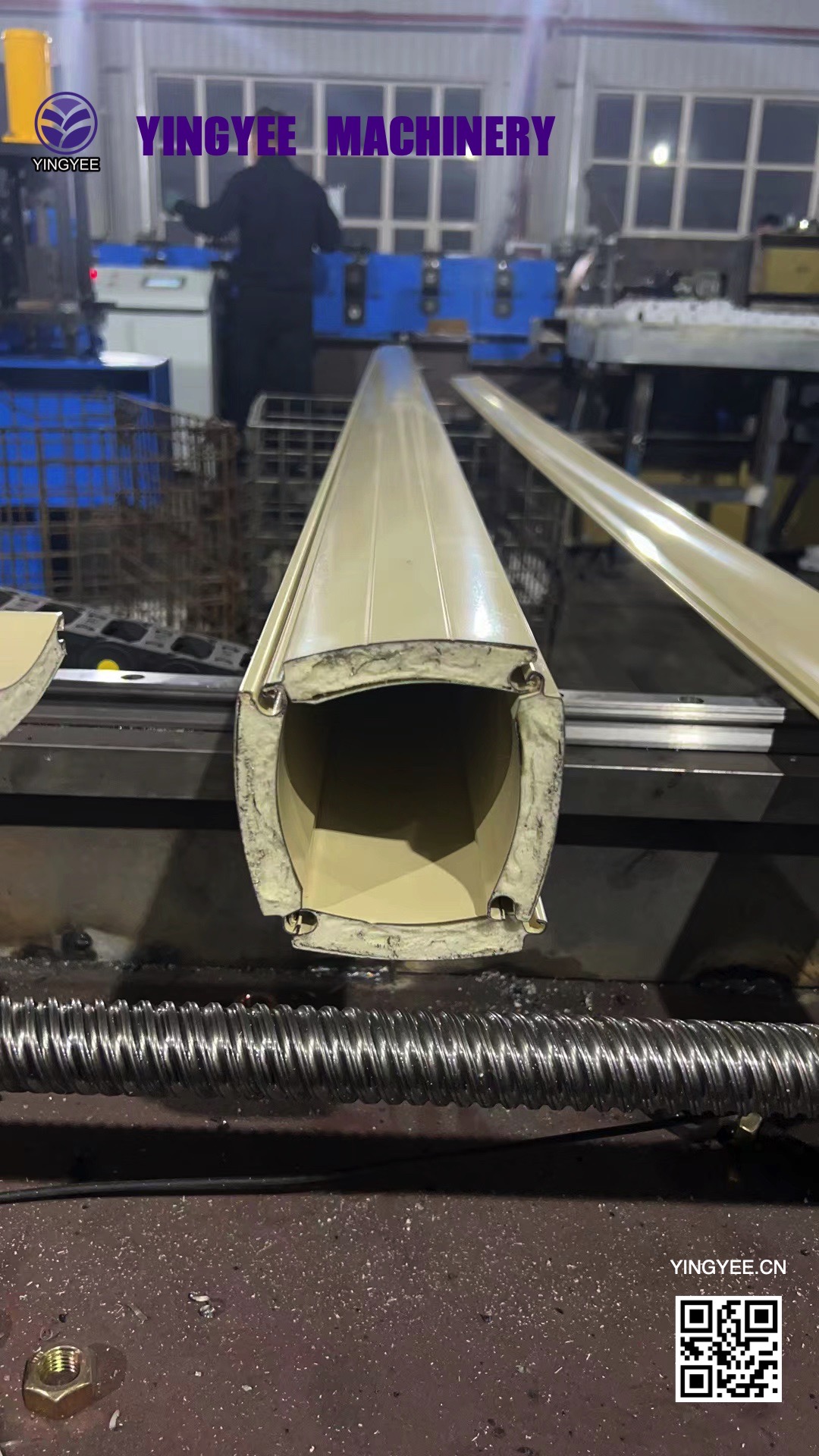

Cold forming is a manufacturing process that shapes metal at room temperature. This technique improves the material’s strength without losing ductility. The metal is passed through a series of rollers, which progressively shape it into a predetermined profile. Using this method allows manufacturers to achieve precise dimensions and superior surface finishes, making it an ideal choice for creating rolling doors.

The cold forming process typically involves several steps. Initially, a metal coil is fed into the machine. Through a series of rollers and dies, the metal is shaped into the desired form. The process may include cutting, bending, and additional shaping, depending on the specifications of the door being produced. The entire operation is automated, which enhances efficiency and reduces labor costs.

Key Advantages of Metal Rolling Door Cold Forming Machines

1. Cost-Effectiveness One of the main advantages of using cold forming machines is their efficiency in material usage. The process generates minimal waste, making it a cost-effective choice for mass production. Additionally, the automation reduces labor costs and time, further increasing the overall profitability of the production process.

2. Enhanced Durability Rolling doors made with cold-formed metal are known for their strength and durability. The cold forming technique enhances the structural integrity of the metal, making these doors less likely to warp, bend, or break under pressure. This durability is crucial in commercial environments where security is paramount.

3. Versatility Metal rolling door cold forming machines can be adapted to create various door designs and styles. This versatility allows manufacturers to cater to a diverse range of customer needs, from residential garages to large industrial facilities.

4. Low Maintenance Cold-formed metal doors require minimal maintenance compared to traditional alternatives. Their robust design ensures that they can withstand harsh environmental conditions without significant deterioration, offering long-term value to businesses.

5. Aesthetic Flexibility The technology also allows for a variety of finishes and coatings on the metal doors, which can be tailored to meet specific aesthetic requirements. This customization capability helps businesses maintain their brand identity while ensuring functionality and security.

Applications of Metal Rolling Door Cold Forming Machines

The applications of metal rolling doors are vast and varied. These doors are commonly used in commercial and industrial settings such as warehouses, factories, and retail stores. Their ability to provide security while allowing for easy access makes them an ideal choice for loading docks and service entrances.

Additionally, metal rolling doors are increasingly being adopted in residential settings. Homeowners seek these doors for garages and utility spaces due to their blend of aesthetic appeal and functionality. Moreover, the ability to insulate these doors effectively makes them suitable for climates that require temperature control.

Conclusion

The advancement of metal rolling door cold forming machines represents a significant step forward in the manufacturing sector. By combining efficiency, durability, and versatility, these machines streamline the production process and meet the evolving demands of the market. As technology continues to improve, we can expect even more innovations in the design and functionality of metal products, ensuring that the metal rolling door cold forming machine remains a crucial component in modern manufacturing practices. By harnessing these machines, businesses can provide high-quality solutions that address both practical needs and aesthetic preferences, ultimately contributing to the success of their operations.