Understanding Metal Rolling Door Cold Forming Machines

In recent years, the demand for efficient and robust security solutions has significantly risen, leading to the increased popularity of metal rolling doors. These doors not only provide security but also enhance the aesthetic appeal of buildings. The manufacturing of these doors relies heavily on advanced machinery, particularly cold forming machines. In this article, we will delve into the importance of metal rolling door cold forming machines, their functionality, and their advantages in the production process.

What is a Cold Forming Machine?

Cold forming is a manufacturing process where metal is shaped at room temperature using processes such as bending, folding, and rolling. Unlike traditional forging methods that apply heat, cold forming allows for the creation of stronger metal components without the need for heating, thus preserving the material's integrity. Metal rolling door cold forming machines are specialized equipment designed to produce the various components required for rolling doors efficiently.

How Does Cold Forming Work?

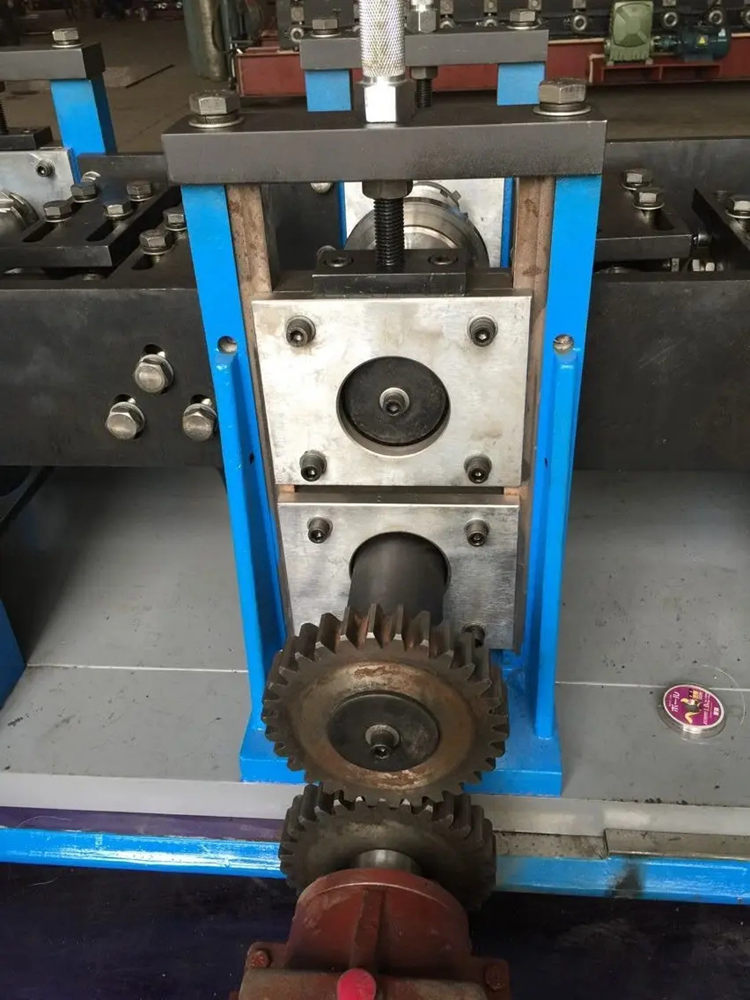

The cold forming process involves several steps. Initially, metal strips or sheets are fed into the machine. The cold forming machine utilizes rollers and dies to shape the metal into the desired form. Through a series of precise movements, the machine bends and shapes the metal into the various profiles needed for the rolling door frames, slats, and tracks. This process can be easily adapted to produce different designs and sizes, making it highly versatile for manufacturers.

Benefits of Using Cold Forming Machines

1. Enhanced Material Strength Cold forming enhances the material's strength due to the work hardening effect. The process increases the density of the metal, making it less prone to bending, breaking, or flexing under pressure. This characteristic is particularly important for rolling doors, which must withstand forces such as wind, impact, and unauthorized access attempts.

2. Cost Efficiency Cold forming machines optimize the material usage by minimizing waste during the production process. Additionally, the high-speed operation of these machines reduces labor costs and production time, ultimately resulting in significant savings for manufacturers.

3. Consistent Quality The automated nature of cold forming machines ensures uniformity and consistency in the production of rolling door components. This level of precision leads to better fitting and enhanced performance of the final products. Moreover, manufacturers can maintain tighter tolerances and achieve superior surface finishes, contributing to the overall quality of the rolling doors.

4. Flexibility and Customization Modern cold forming machines are equipped with advanced technology that allows for easy adjustments and custom configurations. Manufacturers can quickly switch between different profiles or designs, enabling them to respond to market demands and customer preferences without significant downtime.

5. Reduced Energy Consumption Unlike traditional metal forming processes that require heating the metal, cold forming machines operate at lower energy levels. This not only reduces the operational costs but also makes the process more environmentally friendly, as it results in a lower carbon footprint.

Conclusion

The metal rolling door cold forming machine is a vital tool in the manufacturing of secure and durable rolling doors. It combines efficiency, strength, and flexibility to meet the growing demands of the construction and security industries. As the technology continues to evolve, manufacturers can expect even greater enhancements in production speed, energy efficiency, and material handling.

Investing in high-quality cold forming machinery is essential for companies aiming to maintain a competitive edge in the market. By embracing the benefits of cold forming, they can produce superior products that meet the high standards expected by consumers today. Moreover, as security concerns remain paramount, the importance of reliable metal rolling doors will continue to grow, solidifying the role of cold forming machines in this industry.

In summary, the metal rolling door cold forming machine is not just a manufacturing tool; it is a game-changer in the production landscape, enabling manufacturers to deliver top-notch products that provide safety and security while also catering to aesthetic needs.