Metal Strut Channel Roll Forming Machine An Overview

The construction and manufacturing industries have seen significant advancements in technology over the years, with one notable innovation being the metal strut channel roll forming machine. This piece of equipment is instrumental in producing strut channels, which are essential components in various structural and support applications. This article delves into the functionality, benefits, and considerations of using a metal strut channel roll forming machine.

What is a Metal Strut Channel?

Strut channels, often referred to as strut or channel, are metal frames or supports designed to provide structural support for a wide range of applications, including electrical and plumbing installations, HVAC systems, and general construction projects. These channels are characterized by their C-shaped cross-section, which allows them to bear significant loads while remaining lightweight and easy to handle. Strut channels are often made from steel or aluminum, offering durability and strength.

Functionality of the Roll Forming Machine

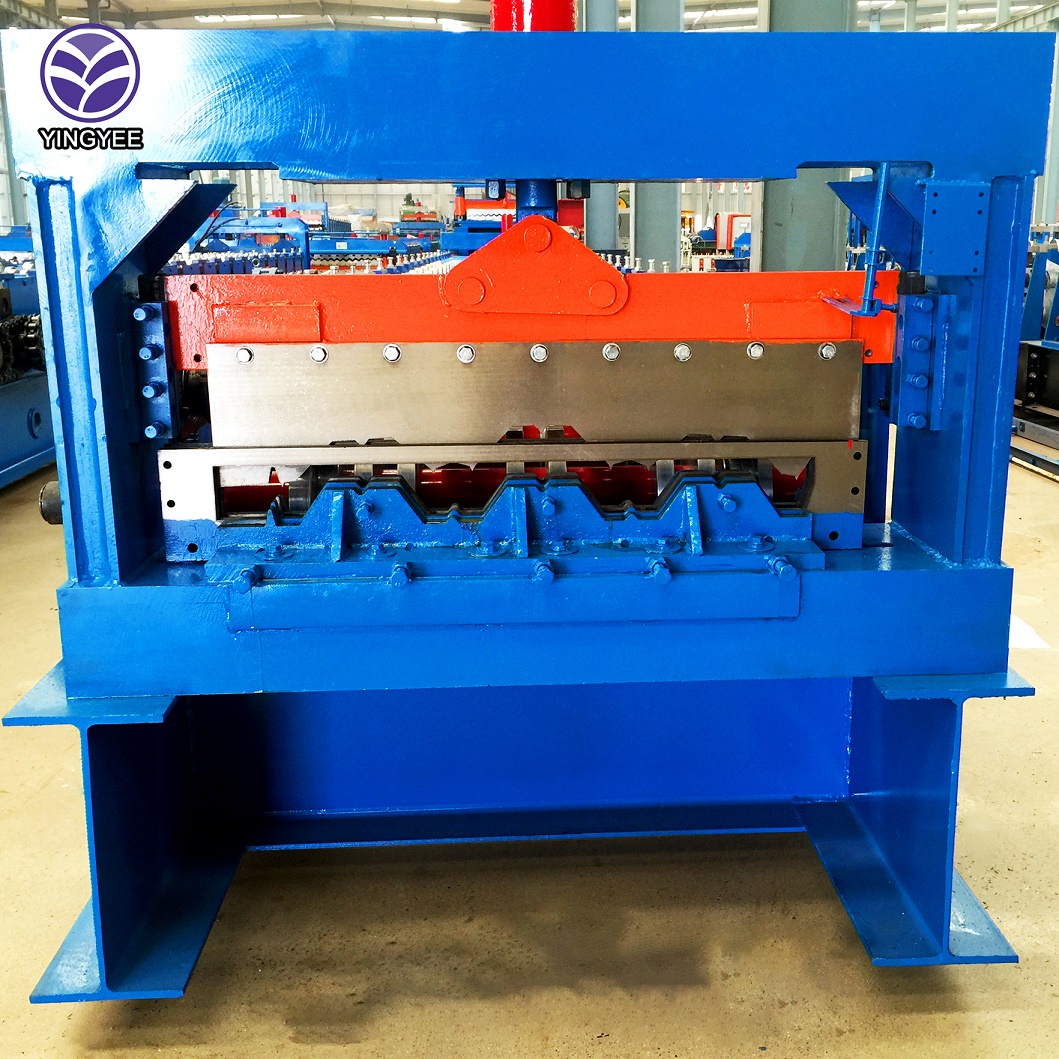

A metal strut channel roll forming machine operates by continuously feeding a flat strip of metal through a series of rollers that gradually shape it into the desired channel profile. The machine is equipped with precision tooling that ensures high accuracy in the final product dimensions. The roll forming process is efficient, allowing for the mass production of strut channels with minimal waste.

The roll forming machine can be programmed to produce different sizes and designs of strut channels, making it versatile for various applications. Advanced machines incorporate features such as automatic length cutting, punching holes, and bending, which enhance their productivity and reduce the need for secondary operations.

Advantages of Using a Roll Forming Machine

1. Efficiency Metal strut channel roll forming machines streamline the manufacturing process. They can produce large quantities of strut channels in a short amount of time, significantly reducing production time compared to traditional methods.

2. Cost-Effectiveness By minimizing material waste and maximizing production speed, roll forming machines contribute to lower manufacturing costs. Additionally, the durability and strength of the channels reduce the need for frequent replacements or repairs.

3. Customization Manufacturers can customize strut channels to meet specific project requirements. This flexibility allows for variations in size, thickness, and shape, accommodating the unique needs of different construction projects.

4. Consistency and Quality The automated nature of roll forming ensures uniformity in product quality. Each strut channel produced maintains the same high standards, which is critical in applications that require precision engineering.

5. Less Labor Intensive With the incorporation of automation and advanced technology, the reliance on manual labor is reduced. This not only cuts labor costs but also mitigates the risks associated with human error.

Considerations When Choosing a Machine

When selecting a metal strut channel roll forming machine, several factors should be taken into account. The machine's specifications, such as production capacity, speed, and power consumption, should be matched to the needs of your manufacturing operation. Additionally, consider the quality of materials used in the machine's construction and the availability of technical support and service.

In conclusion, the metal strut channel roll forming machine is a pivotal tool in modern manufacturing. Its ability to produce high-quality, custom strut channels efficiently and cost-effectively makes it invaluable in the construction industry. As technology advances, these machines will continue to enhance production capabilities and meet the ever-evolving demands of various construction projects. The choice to invest in a roll forming machine today is a step towards a more streamlined and competitive manufacturing future.