The Importance of Metal Roof Sheet Making Machines

In the construction industry, roofing is one of the most critical aspects that influence both the aesthetic appeal and structural integrity of buildings. Among the various materials used for roofing, metal sheets have gained significant popularity due to their durability, energy efficiency, and low maintenance requirements. As the demand for metal roofing continues to rise, the production of metal roof sheet making machines has become increasingly essential.

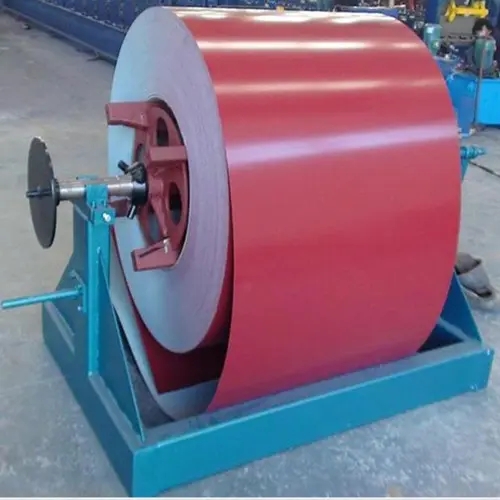

A metal roof sheet making machine is a sophisticated piece of equipment designed to transform raw metal coils into finished roofing sheets. These machines operate through a series of processes that include decoiling, feeding, leveling, and roll forming. The efficiency and precision of these machines play a crucial role in determining the quality of the final product, which is integral to the overall performance of the roofing system.

One of the primary advantages of metal roof sheet making machines is their ability to produce sheets that meet specific customer requirements

. These machines can be customized to create various designs, thicknesses, and profiles, catering to the diverse needs of the construction market. By offering flexibility in production, manufacturers can easily adapt to changing trends and customer preferences, ensuring they remain competitive in the industry.Moreover, metal roof sheet making machines are designed to enhance productivity. With advancements in technology, many of these machines are now equipped with automated features that streamline the production process. Automation reduces the need for manual labor, minimizes the chances of errors, and increases output rates. This efficiency translates to lower production costs, making metal roofing a more affordable option for builders and homeowners alike.

Quality control is another critical factor in roofing production. Metal roof sheet making machines employ advanced technology to ensure that each sheet produced meets stringent quality standards. Features such as computerized control systems and real-time monitoring allow operators to maintain consistent thickness, width, and finish of the sheets. High-quality roofing contributes to the longevity and reliability of buildings, which is paramount in protecting against the elements.

Additionally, the use of metal roof sheets can significantly improve energy efficiency in buildings. Metal roofs reflect solar radiant heat, which can reduce cooling costs in hot climates. As awareness of energy conservation grows, builders and homeowners are increasingly seeking sustainable roofing solutions. By investing in metal roof sheet making machines, manufacturers not only meet market demands but also contribute to a greener environment.

The versatility of metal roof sheets is another reason for their popular adoption. They can be used in various applications, ranging from residential homes to large commercial buildings, agricultural structures, and warehouses. This broad applicability further fuels the demand for metal roof sheet production, making it a lucrative area for manufacturers.

In conclusion, metal roof sheet making machines play a vital role in the construction industry by facilitating the production of high-quality, durable roofing solutions. Their ability to adapt to market needs, enhance productivity, ensure quality, and promote energy efficiency makes them indispensable in today’s building landscape. As the demand for metal roofing continues to grow, investing in advanced metal roof sheet making technology will be essential for manufacturers aiming to thrive in a competitive market. With the right equipment, they can meet the needs of the future while contributing to sustainable building practices.