The world of industrial manufacturing is continuously evolving, and one technology that has made a substantial impact is the roll forming machine. Among the numerous types available, the IBR roll forming machine stands out due to its specialized functionality in producing roofing sheets. If you're considering investing in an IBR roll forming machine, understanding its experience, expertise, authoritativeness, and trustworthiness can greatly aid in making an informed decision.

Experience is a critical factor when evaluating the effectiveness of IBR roll forming machines. These machines are typically known for their robust design and ability to consistently manufacture roofing sheets that meet precision standards. Their use in numerous industrial settings across the globe stands as a testament to their reliability and durability. Companies that have integrated IBR roll forming machines into their production lines often report increased efficiency and reduced waste – factors that are crucial in maintaining a competitive edge in the construction industry. The experience of using these machines translates into faster production cycles, which can significantly enhance project timelines.

Expertise in the field of roll forming is indispensable, particularly when dealing with IBR sheets, which require precision and attention to detail during production. IBR roll forming machines are engineered to handle complex profiles, ensuring that each sheet produced meets the stringent requirements for roofing materials. Expertise is not just about the mechanics; it also involves understanding the materials used and the environmental conditions where these sheets will be deployed. Many manufacturers offer training and support to ensure operators fully understand machine functionality, which helps in optimizing their use and prolonging the machine's lifecycle. This expertise encompasses knowledge from machine calibration to the nuances of material handling.

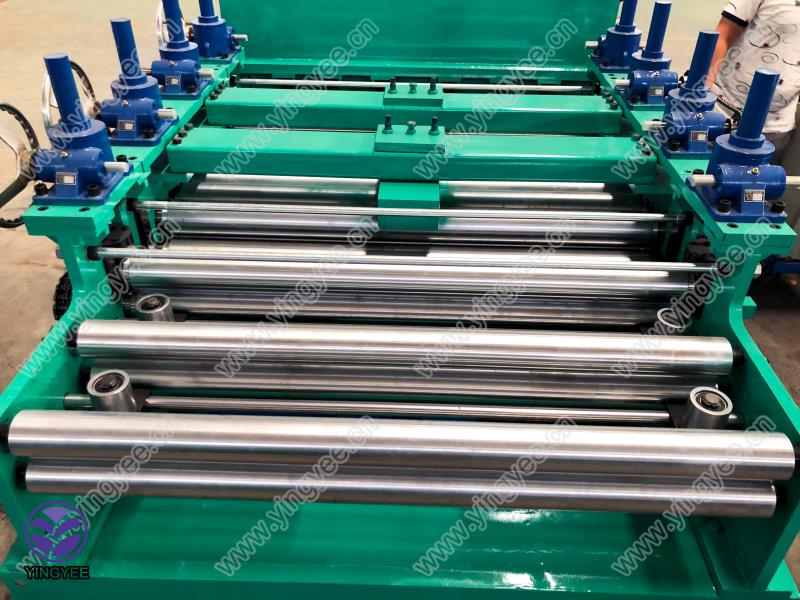

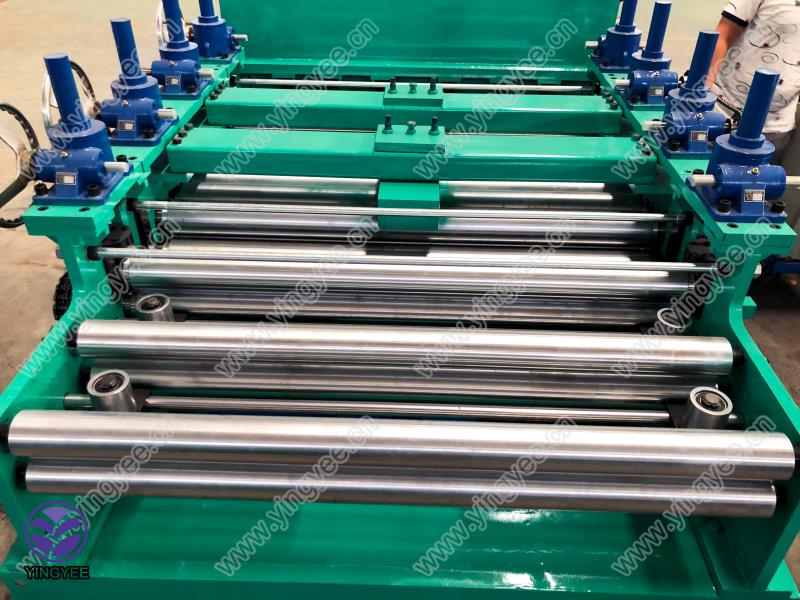

ibr roll forming machine

Authoritativeness in the realm of IBR roll forming is achieved when manufacturers exert influence based on advanced technology and innovation. Leading manufacturers have invested heavily in research and development to ensure their machines are at the forefront of technological advancement. This has resulted in IBR roll forming machines that incorporate cutting-edge features such as automated controls, precise cutting systems, and efficient material feeding mechanisms. Such features not only enhance productivity but also ensure that the end products consistently meet industry standards. The ability of a manufacturer to demonstrate authority in this niche through patented technologies and industry certifications often serves as a crucial deciding factor for businesses looking to invest in high-quality forming machines.

Trustworthiness is the cornerstone of any industrial equipment purchase, and IBR roll forming machines are no exception. Trust is built on a foundation of quality assurance and after-sales support. Reputable manufacturers offer warranties and service agreements that assure buyers of their commitment to product performance. Additionally, customer testimonials and case studies often highlight long-term relationships between buyers and manufacturers, further cementing trust. Trustworthiness also extends to compliance with industry regulations and standards. By choosing IBR roll forming machines from trusted sources, businesses can ensure they are compliant with safety and quality standards, which is critical in maintaining their reputation and avoiding regulatory pitfalls.

In conclusion, investing in an IBR roll forming machine requires careful consideration of experience, expertise, authoritativeness, and trustworthiness. These machines play a pivotal role in the efficient production of high-quality roofing sheets, which are an essential component in the construction industry. By focusing on these four key dimensions, businesses can not only optimize their production processes but also secure a strong position in the competitive industrial landscape. Whether enhancing current production capabilities or entering into new markets, the right IBR roll forming machine can provide the competitive edge needed to thrive.