High Straightness Drywall Machine The Hot-Selling Solution for Modern Construction

In the ever-evolving landscape of construction technology, the high straightness drywall machine stands out as a revolutionary product that addresses the critical demands of the industry. With the goal of enhancing efficiency, precision, and overall quality in drywall installation, this innovative machine has become a hot seller among contractors, builders, and construction professionals worldwide.

The Importance of Precision in Drywall Installation

Drywall installation is a fundamental aspect of modern construction, serving as the backbone for interior walls and ceilings. The quality of drywall work can significantly impact the aesthetic appeal and structural integrity of a building. Therefore, achieving high levels of precision in cutting and finishing drywall panels is crucial. Traditional methods often lead to inconsistencies, which can result in costly repairs and additional labor. This is where high straightness drywall machines come into play, offering solutions that not only streamline the process but also enhance the quality of the final product.

Key Features of High Straightness Drywall Machines

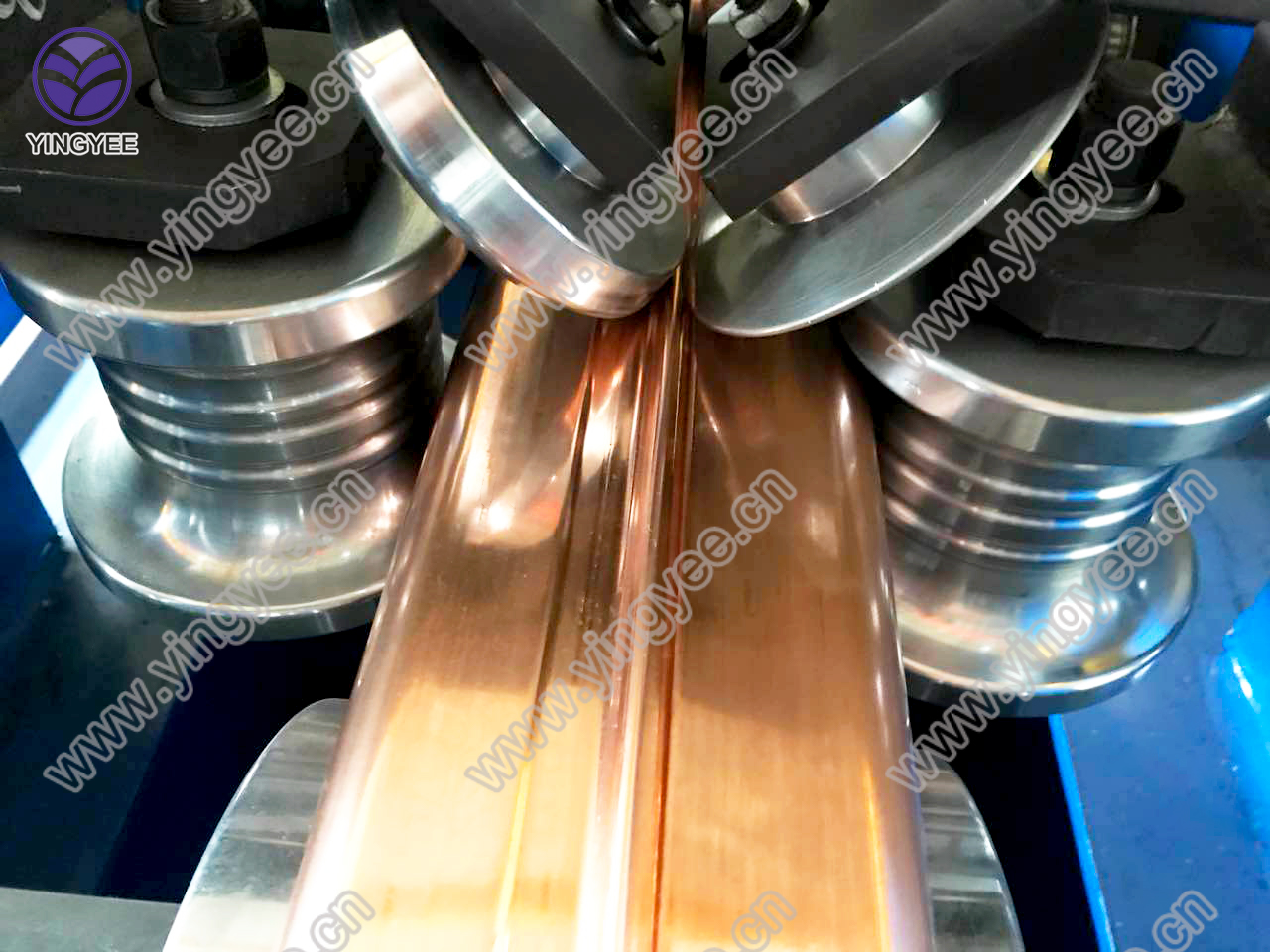

1. Advanced Cutting Technology High straightness drywall machines are equipped with state-of-the-art cutting technology that ensures perfectly straight edges, minimizing the need for manual adjustments. This precision reduces waste and enhances the overall efficiency of the installation process.

2. Speed and Efficiency One of the standout features of these machines is their ability to work quickly without sacrificing quality. With automated processes, contractors can significantly reduce the time spent on drywall preparation, allowing them to take on more projects and increase profitability.

3. User-Friendly Operation Modern high straightness drywall machines are designed with the user in mind. Many models feature intuitive controls and easy setup processes, enabling operators of varying skill levels to achieve professional results. This accessibility makes them an attractive option for both seasoned professionals and newcomers to the industry.

4. Durable Construction Built to withstand the rigors of daily use, these machines are often constructed from high-quality materials. They are designed to endure the wear and tear of construction sites, ensuring longevity and reliable performance over time.

5. Versatility High straightness drywall machines are capable of handling a variety of drywall types and sizes, making them suitable for a wide range of applications. This versatility allows contractors to adapt to the specific needs of each project, from residential renovations to large-scale commercial builds.

Why the Demand is Soaring

The surge in demand for high straightness drywall machines can be attributed to several factors. As construction industry standards evolve, there is an increasing emphasis on quality and efficiency. Builders and contractors are constantly seeking ways to enhance productivity and reduce costs, making these machines a highly attractive investment. Additionally, the growing trend toward sustainable construction practices aligns well with the efficiency offered by these machines, as they minimize waste and promote better resource management.

Furthermore, as more projects embrace an aesthetic that values clean lines and seamless finishes, the ability to achieve straight and precise drywall installations has never been more important. The demand for high-quality finishes has led to a rise in the adoption of high straightness drywall machines, cementing their place as essential tools in modern construction.

Conclusion

The high straightness drywall machine represents a significant advancement in drywall installation technology. With its unmatched precision, speed, and user-friendly design, it addresses the pressing demands of today’s construction industry. As contractors and builders increasingly recognize the value of investing in such innovative solutions, it’s clear that high straightness drywall machines are not just a passing trend but a cornerstone of future-proof construction practices. For those looking to enhance their drywall installation processes, embracing this technology is a step towards greater efficiency, quality, and profitability in the competitive construction market.