The innovative h2 w4 spacer cold bending machine stands at the forefront of industrial advancements, particularly revered for its precision and reliability in various manufacturing sectors. Unlike conventional methods, this machine offers unparalleled efficiency, revolutionizing how industries approach spacer fabrication.

Experience in the field of cold bending machines highlights their transformative impact on production lines. Operators switching to the h2 w4 spacer cold bending machine report a noticeable increase in output quality and consistency. Unlike traditional bending methods that often result in material fatigue, this machine uses state-of-the-art cold bending technologies to maintain the integrity of materials, ensuring that each spacer is resilient and free from stress-induced defects. As a result, companies experience fewer recalls and reduced material wastage, translating into cost savings and increased client satisfaction.

From an expertise standpoint, the h2 w4 model integrates advanced features that set it apart from its counterparts. It employs precise control mechanisms that allow for micro-adjustments, catering to a wide range of specifications with minimal effort. This adaptability is critical for industries like automotive and aerospace, where accuracy cannot be compromised. Users with technical proficiency laud its user-friendly interface that seamlessly blends automation with manual controls, offering an intuitive experience that minimizes the learning curve for new operators. This cohesion of technology and human oversight exemplifies a modern approach to machine design, underlining its status as a product of expert engineering.

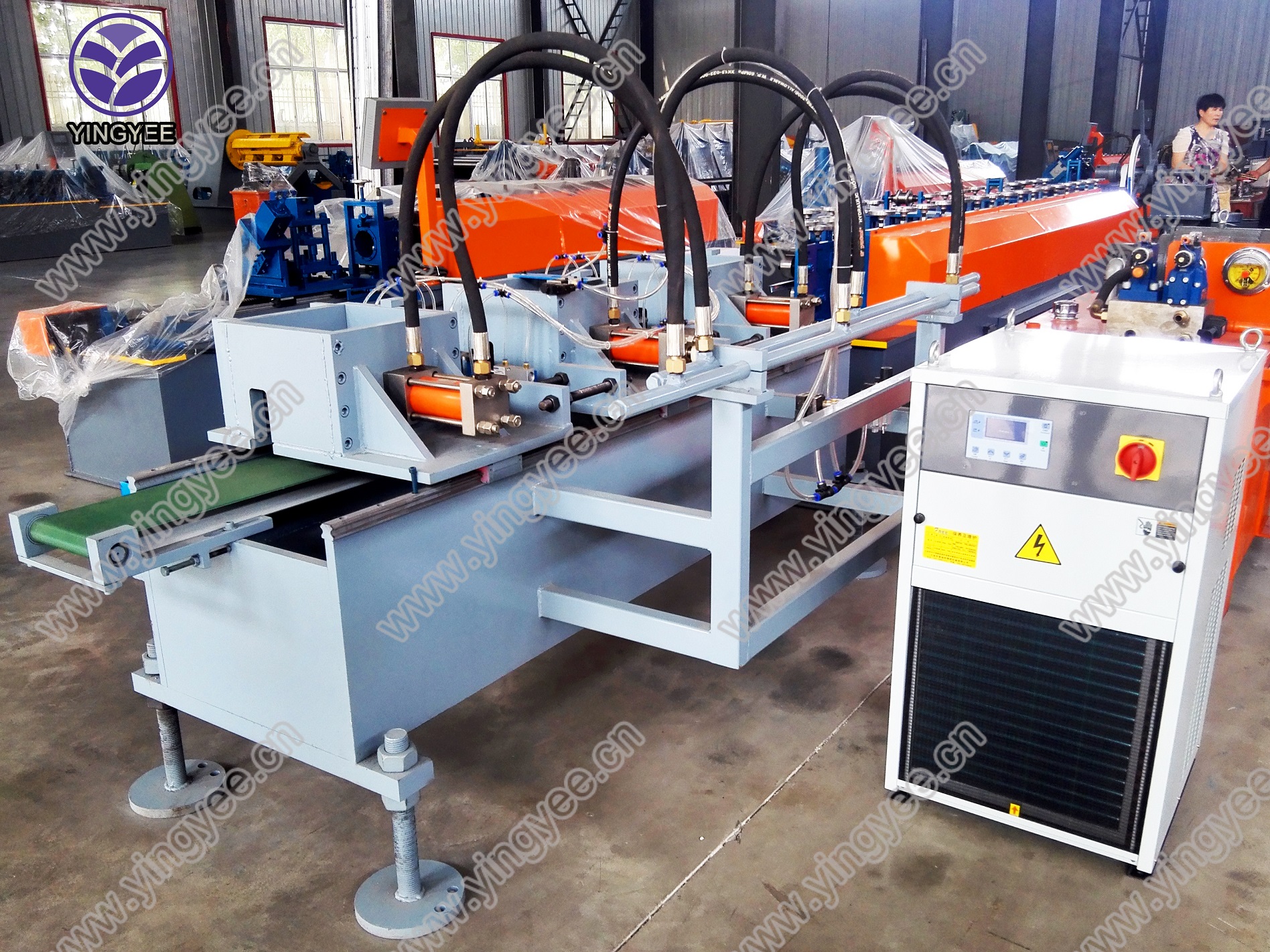

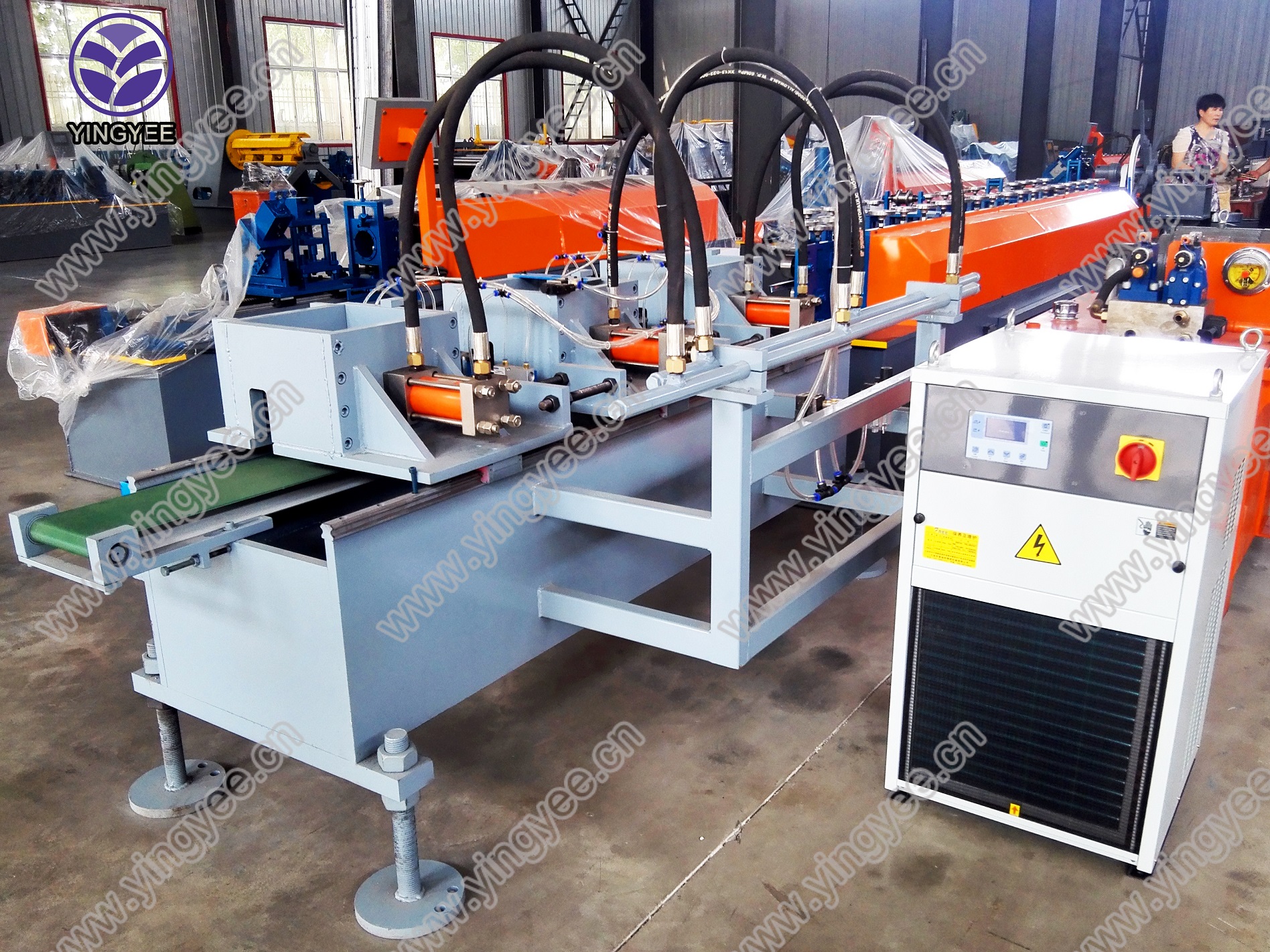

h2 w4 spacer cold bending machine

The authority this machine commands in the industry stems from rigorous testing and ongoing innovations by leading engineering teams. Backed by certifications from recognized industry bodies, the h2 w4 spacer cold bending machine adheres to global standards, assuring users of its quality and safety. Third-party reviews frequently highlight its robust construction and reliability, often emphasizing its durability under continuous operation. This machinery is not just a tool but a long-term investment, offering returns through sustained performance even in demanding environments. Endorsements from well-established companies further cement its role as a pivotal asset in modern production facilities.

Trustworthiness is a hallmark of the h2 w4 spacer cold bending machine’s design philosophy. The manufacturers prioritize transparency and support, providing extensive documentation and access to a dedicated customer service team. This commitment ensures that all user inquiries are promptly addressed, fostering an environment of trust and reliability. Moreover, the machine’s design incorporates environmentally conscious principles, using energy-efficient components to reduce its carbon footprint. This aspect of sustainability appeals to businesses aiming to enhance their green credentials while maintaining operational efficiency.

In conclusion, the h2 w4 spacer cold bending machine is more than just an industrial tool; it is a testament to cutting-edge engineering that brings together precision, reliability, and innovative technology. Its reputation is built on a foundation of experience and expertise, solidified through authoritative validation and trusted by users worldwide. For industries seeking to enhance their production capabilities, this machine is a valuable ally, offering a blend of performance and sustainability that meets the challenges of modern manufacturing.