The manufacturing landscape for galvanized pipe making machines is a fascinating nexus of technology, engineering prowess, and industrial strength. As more industries lean into infrastructure development and construction, the demand for galvanized pipes, revered for their corrosion resistance and durability, has surged. Galvanized pipe making machines, therefore, play a critical role in meeting this demand, offering a seamless method to turn raw steel into a finished product ready for construction sites, plumbing needs, and beyond.

At the heart of these machines is advanced engineering. The process typically begins with raw steel strips, which are passed through specific rollers to form a pipe. What sets the galvanized pipe manufacturing process apart is the subsequent zinc coating, a process designed to imbue the steel with unparalleled resistance to rust. This transformation is where the synergy of metalwork and chemical engineering truly shines, reflecting the necessity of expertise and precision in producing top-grade galvanized pipes.

Choosing the right galvanized pipe making machine hinges on several factors capacity, automation degree, energy efficiency, and technological sophistication. High-capacity machines are typically favored by large-scale operations where continuous production is paramount. These machines often boast automation features that streamline production, reducing labor costs and minimizing human error. Advanced machines also offer energy-saving features, aligning with the global shift towards more sustainable manufacturing practices.

An authoritative understanding of these machines also encompasses knowledge of the specific galvanization techniques employed. Hot-dip galvanizing remains a popular choice, wherein the steel is submerged in molten zinc, ensuring comprehensive coating. Electro-galvanizing, while yielding a thinner zinc layer, offers a more uniform finish and is suitable for precision applications where exacting surface conditions are required. Selecting the right technique is crucial, influencing both the durability of the pipes and the efficiency of the manufacturing process.

From an experience perspective, operating galvanized pipe making machines requires a blend of technical know-how and practical expertise. Machine operators are often seasoned professionals with a deep understanding of metal properties and mechanical systems. Their role cannot be overstated, as they monitor production lines, conduct quality checks, and ensure that every pipe meets stringent industry standards.

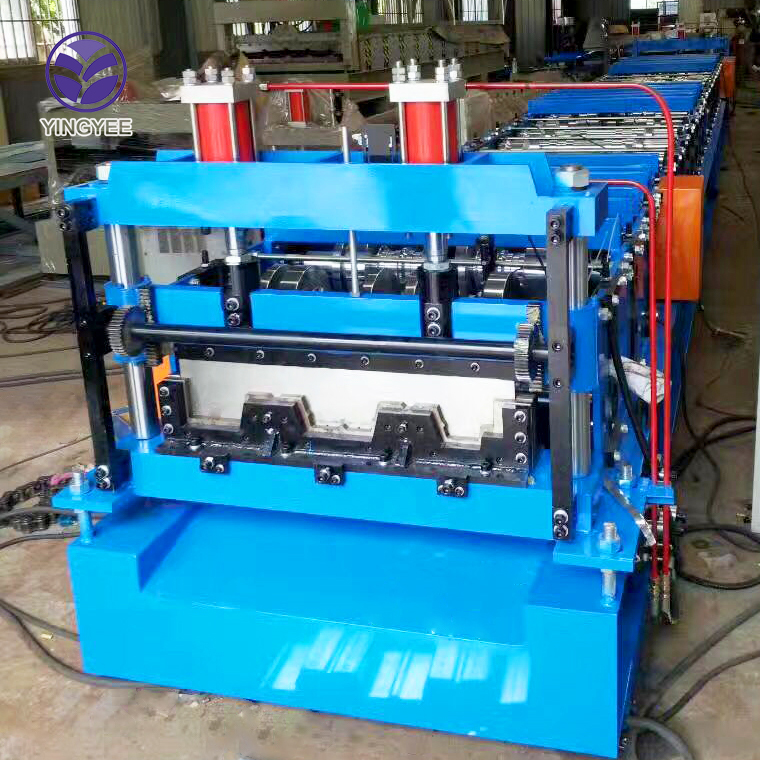

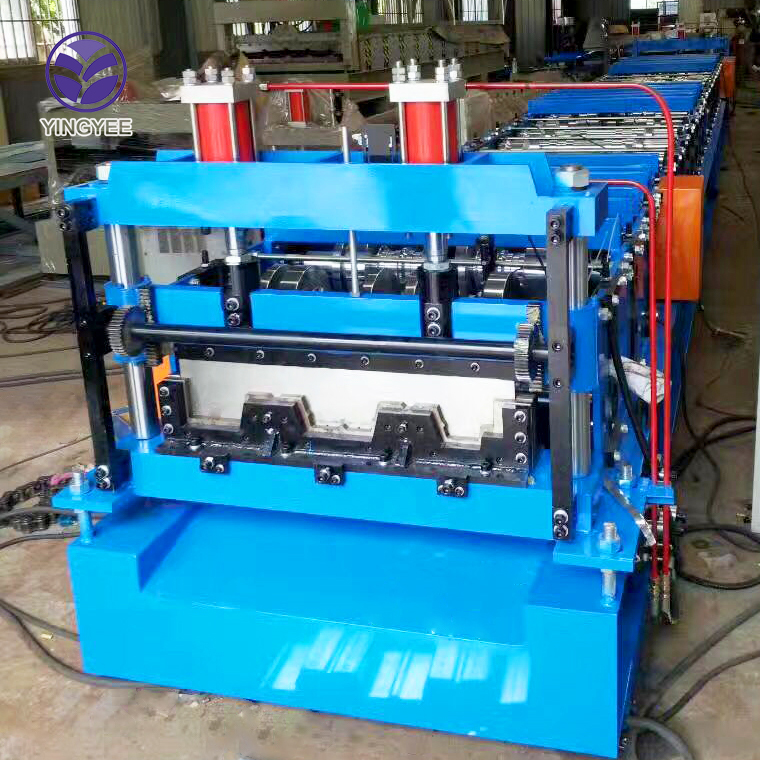

galvanized pipe making machine

For businesses eyeing investment in galvanized pipe making machines, trustworthiness of the supplier is a pivotal consideration. Reliable manufacturers have built their reputations on consistent quality, technological innovation, and robust customer support. Reputable suppliers not only provide cutting-edge equipment but also offer comprehensive training and maintenance services, ensuring that the machines operate at peak efficiency and longevity is maximized.

Engaging with industry experts, whether through professional forums, trade shows, or direct consultations, enhances the decision-making process. These interactions provide invaluable insights into the latest technological advancements, market trends, and regulatory changes impacting the galvanized pipe industry. They allow companies to make informed choices that will future-proof their operations and maintain their competitive edge.

As technologies advance, the future of galvanized pipe making machines looks set to undergo significant transformations. Innovations in automation, materials science, and data analytics are poised to drive further efficiencies, reducing waste and improving the precision of the galvanization process. As these advancements unfold, staying abreast of the latest developments will be crucial for any entity involved in the manufacture or utilization of galvanized pipes.

In conclusion, galvanized pipe making machines are indispensable assets in the industrial landscape, driving the production of pipes that form the backbone of many construction and plumbing projects. A detailed understanding of the engineering, operation, and maintenance of these machines ensures that industries can meet current demands while positioning themselves for future innovations. Whether you’re a seasoned industry professional or a newcomer seeking to explore this fascinating field, the insights provided here are designed to guide your journey through the intricate and rewarding world of galvanized pipe manufacturing.