Double Sheets Roll Forming Machine An Overview

In the world of manufacturing, the roll forming process is a critical technique used to create complex shapes and profiles from metal sheets. Among the various innovations in this field, the double sheets roll forming machine has emerged as a significant advancement, playing a vital role in enhancing efficiency and output quality in production lines. This article will explore the workings, applications, and advantages of double sheets roll forming machines.

What is a Double Sheets Roll Forming Machine?

A double sheets roll forming machine specializes in processing two layers of metal sheets simultaneously. This method not only improves productivity but also allows for the creation of components with varied material properties. The machine operates through a series of rollers that incrementally shape the metal sheets as they pass through, transforming flat materials into desired profiles in continuous motion.

How Does It Work?

The operation of a double sheets roll forming machine involves several key components

1. Feeding System This system is responsible for aligning and feeding the two sheets into the roll forming line. Accurate feeding is essential to ensure that both sheets are processed uniformly and at the correct speed.

2. Roller Stations The core of the roll forming machine consists of multiple roller stations, each designed to progressively shape the sheets. The rolls are typically made of high-strength steel and are precisely engineered to achieve the desired shape at each stage.

3. Cutting Mechanism After the sheets have been formed into the required profile, they typically pass through a cutting mechanism. This can be either a shear or a laser cutter, depending on the material and the specific requirements of the finished product.

4. Control System Modern double sheets roll forming machines are equipped with advanced control systems that allow for real-time adjustments to speed, feed rate, and positioning, ensuring high precision and adaptability to various production needs.

Applications of Double Sheets Roll Forming Machines

Double sheets roll forming machines are widely used in various industries, including

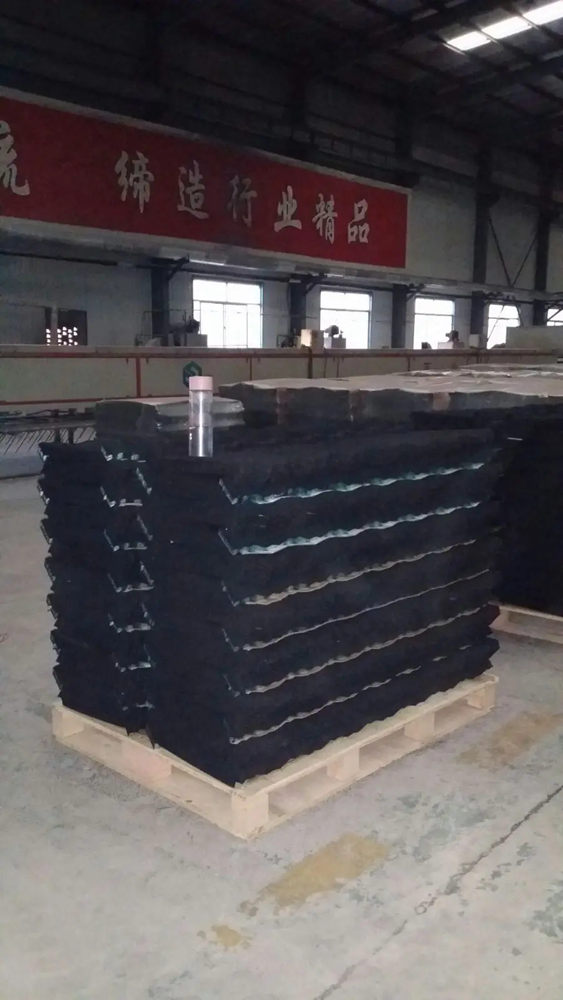

- Construction They produce components like roofing sheets, wall panels, and structural profiles that are crucial for building infrastructure. - Automotive The automotive sector utilizes these machines for manufacturing parts such as body panels and frame components, benefiting from weight reduction and enhanced strength. - Appliances Many household appliances require metal parts that can be efficiently produced using double sheets roll forming, leading to cost-effective manufacturing processes. - Electrical In the production of electrical enclosures and components, double sheets help improve durability and thermal efficiency.

Advantages of Double Sheets Roll Forming Machines

The implementation of double sheets roll forming machines in manufacturing processes offers several benefits

1. Increased Efficiency By processing two sheets at once, these machines significantly reduce production time and labor costs, optimizing throughput.

2. Material Savings The ability to use two layers allows manufacturers to mix materials, achieving desired properties such as enhanced strength while reducing overall material usage.

3. Reduced Waste The precision of the roll forming process minimizes scrap material generated during production, contributing to more sustainable manufacturing practices.

4. High Quality The continuous forming process improves the consistency and quality of the final products, meeting stringent industry standards.

5. Flexibility These machines can be adjusted to accommodate a wide range of metal types and thicknesses, making them adaptable to various production requirements.

Conclusion

The double sheets roll forming machine represents a significant leap in manufacturing technology, especially in sectors where efficiency, quality, and cost-effectiveness are paramount. As industries evolve and the demand for innovative solutions grows, the role of double sheets roll forming machines is likely to expand, paving the way for new applications and further advancements in production technology. This machine not only revolutionizes the way metal components are fabricated but also reinforces the importance of innovation in modern manufacturing.