In the ever-evolving landscape of manufacturing, the corrugated sheet forming machine has emerged as a transformative tool, offering significant advancements in the production of corrugated sheets. These machines, vital to construction and packaging industries, streamline the processes that meet both economic and environmental demands. By understanding the nuanced functionalities and benefits of the corrugated sheet forming machine, businesses can leverage these tools for optimal production efficiency and sustainability.

Corrugated sheet forming machines utilize a series of sophisticated forming processes to transform raw materials, typically metal coils, into precisely shaped corrugated sheets. These sheets are recognized for their durability, structural integrity, and versatility across various applications. The machinery operates through a sequence of cutting-edge mechanisms, including rolling, pressing, and cutting, all meticulously synchronized to ensure uniformity and precision.

A key component of these machines is the roll former, which consists of a series of rollers that systematically shape the metal. The roll forming process entails feeding the sheet through the rollers, which progressively bend the sheet into its desired corrugated profile. This method not only enhances the structural strength of the metal but also allows for high-speed production, making it exceptionally efficient for bulk manufacturing. For businesses focused on scalability and meeting high demands, the corrugated sheet forming machine stands as a cornerstone of operational expansion.

Enhancements in technology have also introduced automation into corrugated sheet forming machines, allowing for greater precision and less human error. These automated systems are equipped with advanced sensors and controls that monitor each stage of production. The automation not only reduces labor costs but also increases the overall safety of the production environment by minimizing direct human intervention. As a result, manufacturers can ensure that the final products adhere to industry standards and customer specifications with minimal deviations.

Another profound advantage lies in the environmental benefits of using a corrugated sheet forming machine. The efficiency of these machines reduces waste by maximizing material use, thus cutting down on scrap and excess. Additionally, the energy-efficient design of modern machines contributes to reduced energy consumption, aligning with sustainable manufacturing practices. Companies are increasingly required to demonstrate environmental responsibility, and investing in energy-efficient machinery is a palpable step towards achieving that goal.

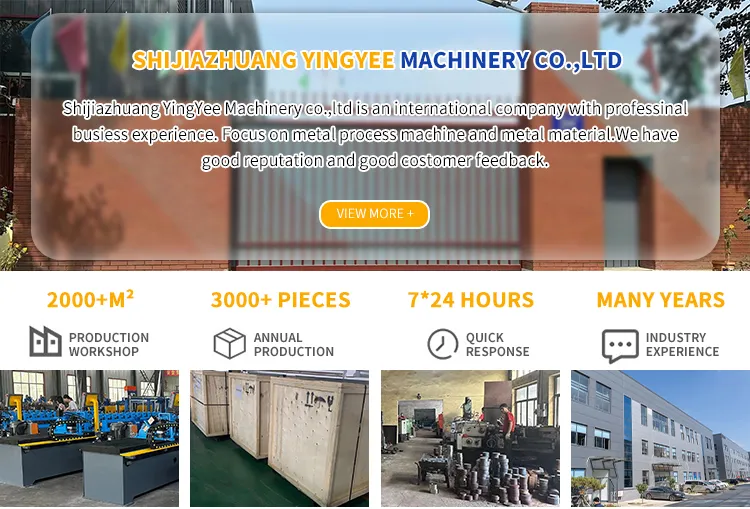

corrugated sheet forming machine

Moreover,

the versatility of corrugated sheets produced by these machines cannot be overstated. From roofing materials and siding for buildings to protective packaging, the range of products that utilize corrugated sheets is extensive. The customizable nature of the sheet forming machine allows manufacturers to adapt to different specifications and market needs swiftly. This adaptability ensures that businesses can meet diverse customer demands without significant retooling or production delays.

Expert operators of corrugated sheet forming machines highlight the importance of routine maintenance and skilled handling. Regular inspections and maintenance routines ensure that machines operate at peak efficiency, reducing costly downtime and extending the equipment's lifespan. Training for operators is equally crucial, as skilled personnel can optimize the machine's capabilities and quickly resolve any operational issues. By investing in professional training and maintenance, businesses safeguard their investment and enhance the reliability of their production processes.

Industry specialists also note the importance of selecting the right machine specifications tailored to business needs. Factors such as sheet thickness, width, material type, and production volume should be carefully considered when acquiring a corrugated sheet forming machine. By aligning the machine’s capabilities with production requirements, businesses can maximize their return on investment and maintain a competitive edge in the marketplace.

In conclusion, the corrugated sheet forming machine is indispensable for modern manufacturing sectors aiming to balance productivity, sustainability, and product quality. By capitalizing on its sophisticated features, environmental efficiency, and robust output, companies bolster their manufacturing capabilities while adhering to regulatory and customer standards. For those navigating the manufacturing domain, understanding and integrating this machinery into operations can serve as a strategic facilitator for enduring success.