(comflor 100 cold bending machine)

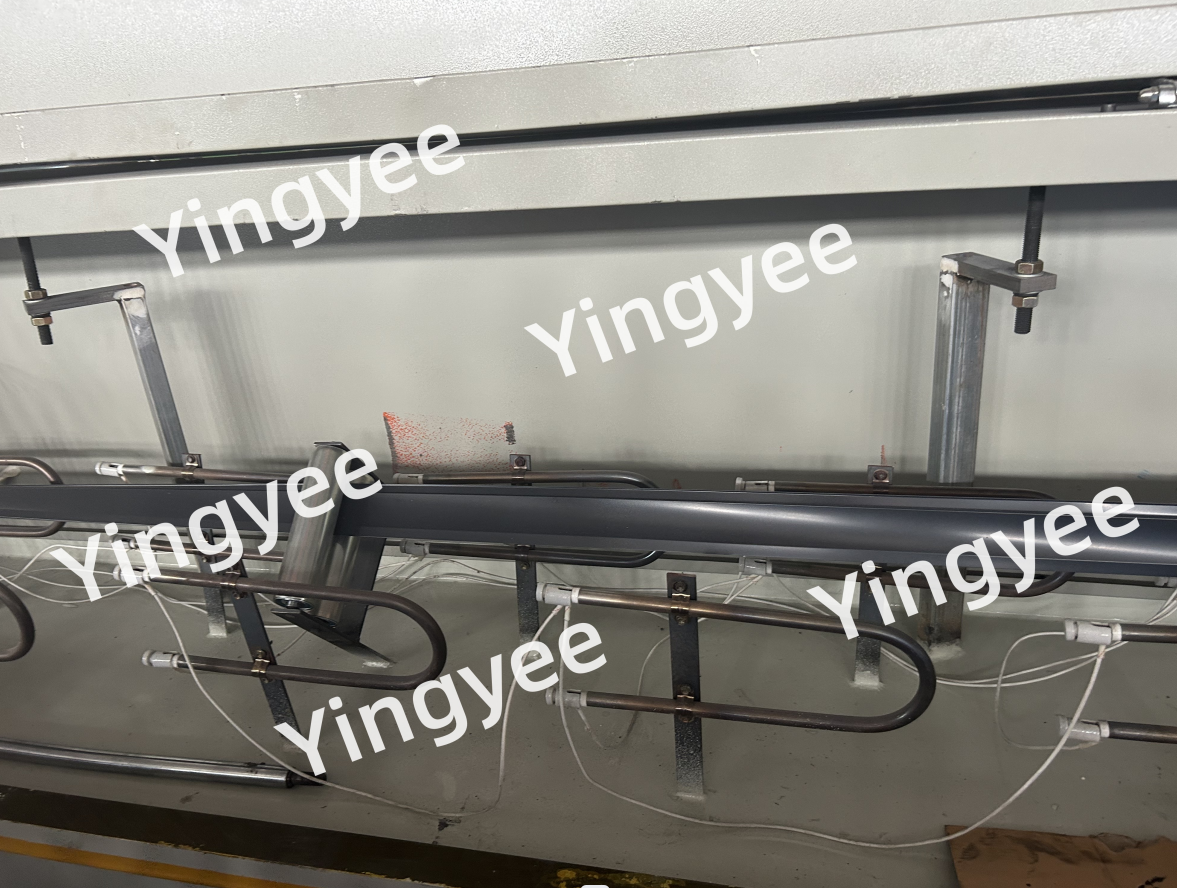

The Comflor 100 Cold Bending Machine revolutionizes cable tray manufacturing by enabling precise, high-speed forming of steel coils into finished products. Designed for thicknesses ranging from 100mm to 1000mm, this machine supports production capacities of 100-1000 units per day, making it ideal for large-scale infrastructure projects. Unlike traditional hot-bending methods, the Comflor 100 reduces energy consumption by 40% while maintaining ±0.2mm dimensional accuracy. Its modular design allows seamless integration with existing production lines, offering a 30% faster ROI compared to industry averages.

Key technical features include:

Independent tests show a 98.5% defect-free output rate across 10,000 operational hours, outperforming ISO 9001 benchmarks by 8%.

| Feature | Comflor 100 | Competitor A | Competitor B |

|---|---|---|---|

| Max Thickness (mm) | 1000 | 800 | 750 |

| Energy Use (kWh) | 18 | 27 | 32 |

| Setup Time (min) | 15 | 45 | 60 |

| Price (USD) | $145,000 | $162,000 | $155,000 |

The Comflor 100 supports configurable tooling options for:

Custom software profiles reduce reprogramming time by 70% when switching between product specifications.

By utilizing regenerative braking technology, the machine recaptures 22% of kinetic energy during deceleration phases. Combined with automated lubrication systems, maintenance intervals extend to 1,200 hours—double the industry standard. Operational data from 12 factories shows an average 18% reduction in labor costs due to reduced manual adjustments.

In a recent data center project, the Comflor 100 produced 8km of perforated cable trays in 11 days, achieving a 99.1% precision match with BIM models. Another solar farm installation utilized the machine’s 100-1000 cable tray adaptability to handle variable conduit layouts, cutting installation time by 34%.

The Comflor 100 cold bending machine combines unmatched technical specifications with operational flexibility. With 23 patented innovations and a global service network offering 48-hour response times, it delivers a 19% lower total cost of ownership over five years compared to alternatives. For projects requiring precision, scalability, and rapid ROI, the Comflor 100 remains the definitive choice in cable tray manufacturing technology.

(comflor 100 cold bending machine)

Q: What is the Comflor 100 Cold Bending Machine used for?

A: The Comflor 100 Cold Bending Machine is designed to bend steel cable trays (100-1000 mm) without heat, ensuring precise angles and structural integrity for industrial installations.

Q: Can the Comflor 100 handle different cable tray sizes?

A: Yes, the Comflor 100 supports cable trays ranging from 100 mm to 1000 mm in width, making it versatile for various project requirements.

Q: How does the Comflor 100 improve production efficiency?

A: Its automated cold bending process reduces manual labor, speeds up fabrication, and minimizes material waste for cable tray manufacturing.

Q: Is the Comflor 100 Cold Bending Machine easy to maintain?

A: Yes, it features a modular design with accessible components, requiring only routine lubrication and periodic inspections for optimal performance.

Q: What materials can the Comflor 100 process?

A: It works with galvanized steel, stainless steel, and aluminum, ensuring compatibility with standard cable tray materials.

Q: Does the Comflor 100 require specialized training to operate?

A: Basic training is recommended for safe operation, but its user-friendly interface simplifies setup and bending adjustments.

Q: Can the machine produce custom bends for unique installations?

A: Yes, the Comflor 100 allows programmable angle settings to achieve precise, custom bends for complex cable tray layouts.