The Evolution of Cold Standing Seam Making Machines

In the realm of modern construction and architecture, the necessity for durable, efficient, and aesthetically pleasing roofing solutions has never been more critical. One of the innovations that have significantly contributed to this need is the cold standing seam making machine. This advanced piece of equipment revolutionizes the way metal roofing panels are formed and installed, leading to enhanced structural integrity and improved weather resistance.

Understanding Cold Standing Seam Technology

Cold standing seam roofing refers to a type of metal roofing system where the seams between panels are raised or standing and are sealed together without the use of exposed fasteners. This system is particularly popular for its sleek appearance and functional design, making it ideal for both commercial and residential applications. The cold standing seam making machine is the key to producing these panels, as it allows for precision engineering in the manufacturing process.

The technology behind these machines has evolved tremendously over the years. Initially, the machinery used for such tasks was bulky, complex, and often required extensive manual labor. However, with advancements in technology, modern cold standing seam making machines are now equipped with automated features, including digital controls and high-speed operation capabilities, which result in faster production times and reduced labor costs.

Key Features of Cold Standing Seam Making Machines

1. Efficiency and Speed One of the standout features of modern cold standing seam machines is their ability to produce panels quickly without sacrificing quality. This rapid production capability is crucial in meeting tight construction deadlines.

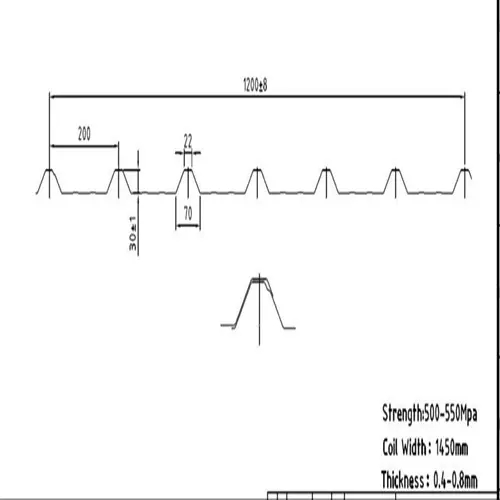

2. Precision and Consistency The modern machines are designed for precise panel dimensions and consistent seam heights, ensuring that each panel fits perfectly during installation. This precision minimizes the risk of leaks and enhances the building's overall durability.

3. Versatility Today's cold standing seam making machines can accommodate a wide range of metal types, including aluminum, steel, and copper, catering to various architectural needs and preferences. Furthermore, many machines can produce panels of different widths and profiles.

4. User-Friendly Operation With intuitive interfaces and programmable controls, these machines allow operators to easily adjust settings for different projects, reducing the learning curve and increasing efficiency.

5. Eco-Friendly Production In an age where sustainability is a priority, many manufacturers have designed their machines to minimize waste during the production process. This aspect not only conserves resources but also helps in reducing the carbon footprint of roofing projects.

Impact on the Roofing Industry

The introduction of cold standing seam making machines has had a profound impact on the roofing industry. First and foremost, the ability to produce high-quality roofing panels in-house allows contractors to reduce dependency on suppliers and mitigate costs. This autonomy also enables quicker turnarounds on projects, which is a critical advantage in competitive markets.

Moreover, as the demand for metal roofs continues to rise due to their longevity and energy efficiency, the cold standing seam making machine provides a reliable solution to meet that demand. This technology not only enhances the functionality of buildings but also contributes to their aesthetic appeal, as architects and builders can create a seamless, modern look for various designs.

Challenges and Future Developments

Despite the advantages, challenges remain in the widespread adoption of cold standing seam making machines. The initial investment costs can be significant for smaller contractors. Additionally, as with any technology, the need for maintenance and skilled operators is paramount to ensure consistent quality.

Looking to the future, advancements in technology such as artificial intelligence and machine learning could further enhance the capabilities of cold standing seam making machines. These innovations may lead to smarter manufacturing processes that can predict and adapt to various production challenges, allowing for even greater efficiency and adaptability in roofing solutions.

Conclusion

Cold standing seam making machines have transformed the roofing industry, setting new standards for efficiency, precision, and design flexibility. As technology continues to evolve, so too will the capabilities of these machines, paving the way for even more innovative and sustainable building solutions in the future. As the demand for high-quality roofing systems grows, the importance of such machinery will undoubtedly remain at the forefront of construction practices worldwide.