The Evolution and Importance of Carbon Steel Square Pipe Making Machines

In the realm of modern manufacturing, carbon steel square pipe making machines play a pivotal role in producing essential components for various industries. From construction to automotive, these machines contribute significantly to the supply chain by providing robust, durable, and versatile pipe products. This article delves into the functionality, advantages, and advancements of carbon steel square pipe making machines.

Understanding Carbon Steel Square Pipes

Carbon steel, known for its strength and malleability, is a widely used material in the production of square pipes. These pipes are characterized by their square cross-section, which makes them ideal for structural applications. They can withstand considerable stress and are resistant to corrosion when treated properly. The square shape offers advantages in construction and design, making them suitable for frames, supports, and other structural components.

Design and Functionality of Pipe Making Machines

Carbon steel square pipe making machines utilize advanced technology to fabricate square pipes from raw steel materials. The production process begins with the feeding of flat steel sheets or strips into the machine. These sheets are then subjected to several mechanical processes, including shearing, bending, and welding, to achieve the desired square shape.

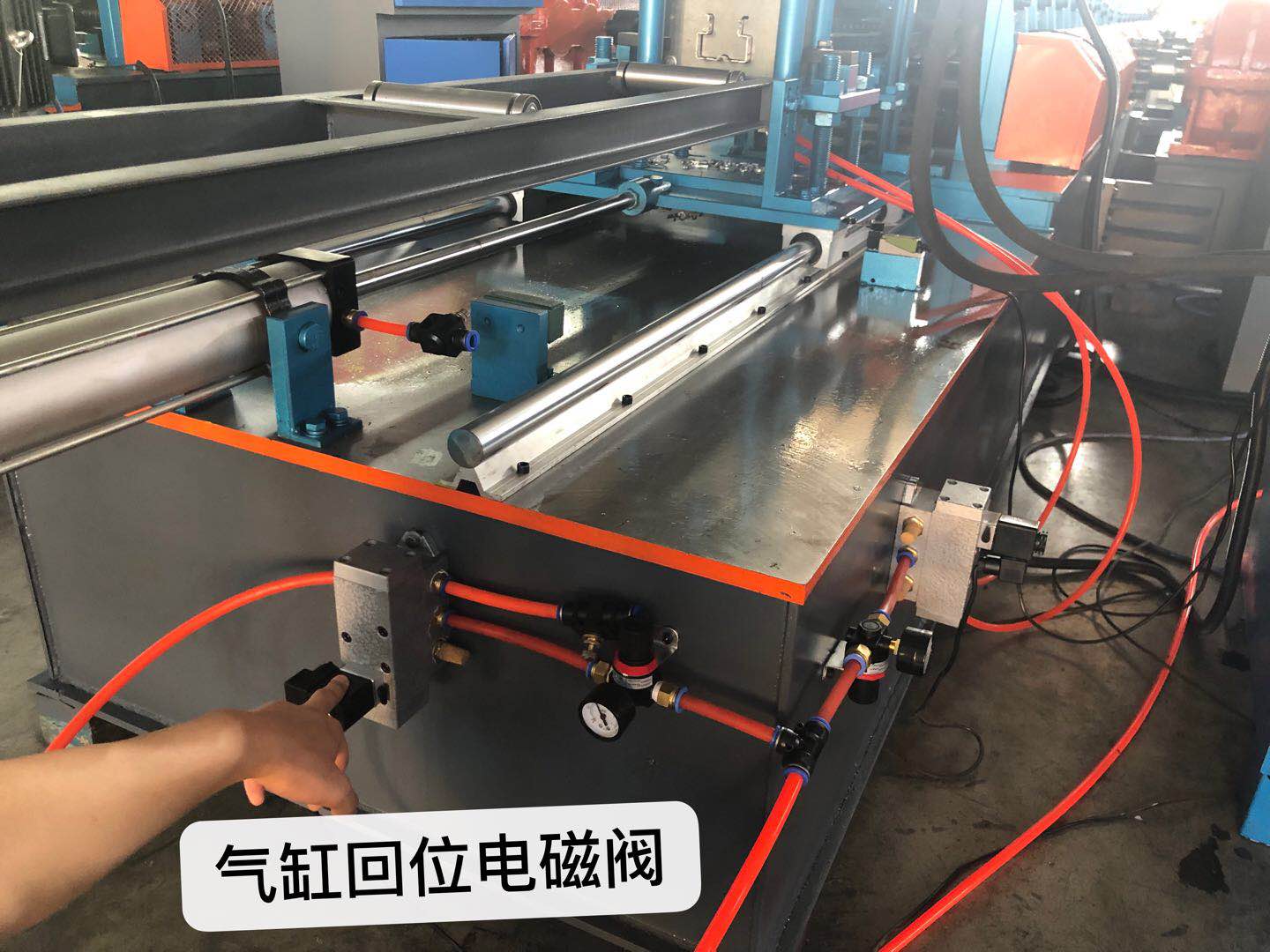

Key components of a typical pipe making machine include

1. Uncoiler This device unwinds the steel strips for processing. 2. Forming Mill This segment gradually shapes the flat strips into a square cross-section using a series of rollers. 3. Welding Station Here, the edges of the formed strips are welded together, creating a continuous pipe. 4. Cooling System After welding, the pipes often undergo cooling to harden the welds and ensure structural integrity. 5. Cutting System Finally, the long lengths of square pipe are cut into specified lengths as per customer requirements.

This systematic approach not only increases productivity but also ensures high precision in the final products.

Advantages of Carbon Steel Square Pipe Making Machines

The adoption of carbon steel square pipe making machines comes with numerous benefits

1. Efficiency Automated processes lead to a significant reduction in production time, allowing manufacturers to meet high demand without compromising quality. 2. Cost-Effectiveness Although the initial investment in machinery can be substantial, the long-term savings associated with reduced labor costs and increased output make these machines a financially sound choice.

3. Versatility Square pipes produced by these machines can be utilized across various sectors, including construction, automotive, furniture, and more. Their adaptability to different specifications makes them a valuable product.

4. Consistency in Quality Advanced technology employed in these machines ensures that each pipe produced meets stringent quality standards. Automated monitoring systems can detect defects in real-time, helping maintain a high level of quality control.

Innovations and Future Trends

The field of carbon steel square pipe production is continually evolving, with innovations aimed at enhancing the efficiency and sustainability of manufacturing processes. The integration of Industry 4.0 principles is becoming more prevalent, incorporating smart technologies such as IoT (Internet of Things), AI (Artificial Intelligence), and machine learning.

These advancements allow manufacturers to monitor machine performance remotely, predict maintenance needs, and optimize production parameters for improved efficiency. Additionally, there is a growing shift towards eco-friendly practices in the industry, with manufacturers exploring ways to reduce waste and lower energy consumption.

Conclusion

In conclusion, carbon steel square pipe making machines are indispensable in the manufacturing sector, offering various advantages that cater to a wide range of industries. As technology continues to advance, these machines are becoming increasingly efficient and sustainable, positioning them at the forefront of modern manufacturing. The significance of square pipes in construction and beyond underscores the importance of investing in quality machinery capable of meeting evolving market demands. With ongoing innovations, the future of carbon steel square pipe making machines looks promising, paving the way for enhanced productivity and sustainability in the manufacturing landscape.