Mastering the craft of manufacturing cable trays involves more than just state-of-the-art machinery; it calls for an understanding that spans years of experience and expertise. For those in the industry, a cable tray making machine is not just a piece of equipment, but a backbone of production efficiency and product quality. By choosing the right machine and optimizing its use, manufacturers can ensure they meet the rigorous demands for safety, versatility, and durability that characterize the market today.

A top-of-the-line cable tray making machine provides unmatched advantages when it comes to the manufacturing process. One of the key elements is precision engineering. The specifications on these machines allow for highly accurate bends and cuts, which are crucial for maintaining structural integrity in the final product. Such precision is integral, as it minimizes waste material and enhances the efficiency of the production line, ensuring cost-effectiveness and sustainability.

Expertise in handling such machines comes with understanding their complex configurations. The best cable tray making machines offer user-friendly interfaces with intuitive controls, which significantly reduce the learning curve. Familiarity with these interfaces allows operators to make quick adjustments on the fly, tailoring the process to specific project needs without sacrificing time or adding costs. A deep comprehension of each machine’s capabilities and maintenance requirements also prolongs its operational life and ensures that production hiccups are minimized.

Incorporating a cable tray making machine into your manufacturing setup demands not only technical know-how but also strategic production planning. Experienced operators can orchestrate production schedules that optimize machine use, maintaining a continuous flow of output without overloading the equipment. This simultaneous optimization of both machine and manpower staves off bottlenecks, improving turnaround times and boosting overall productivity.

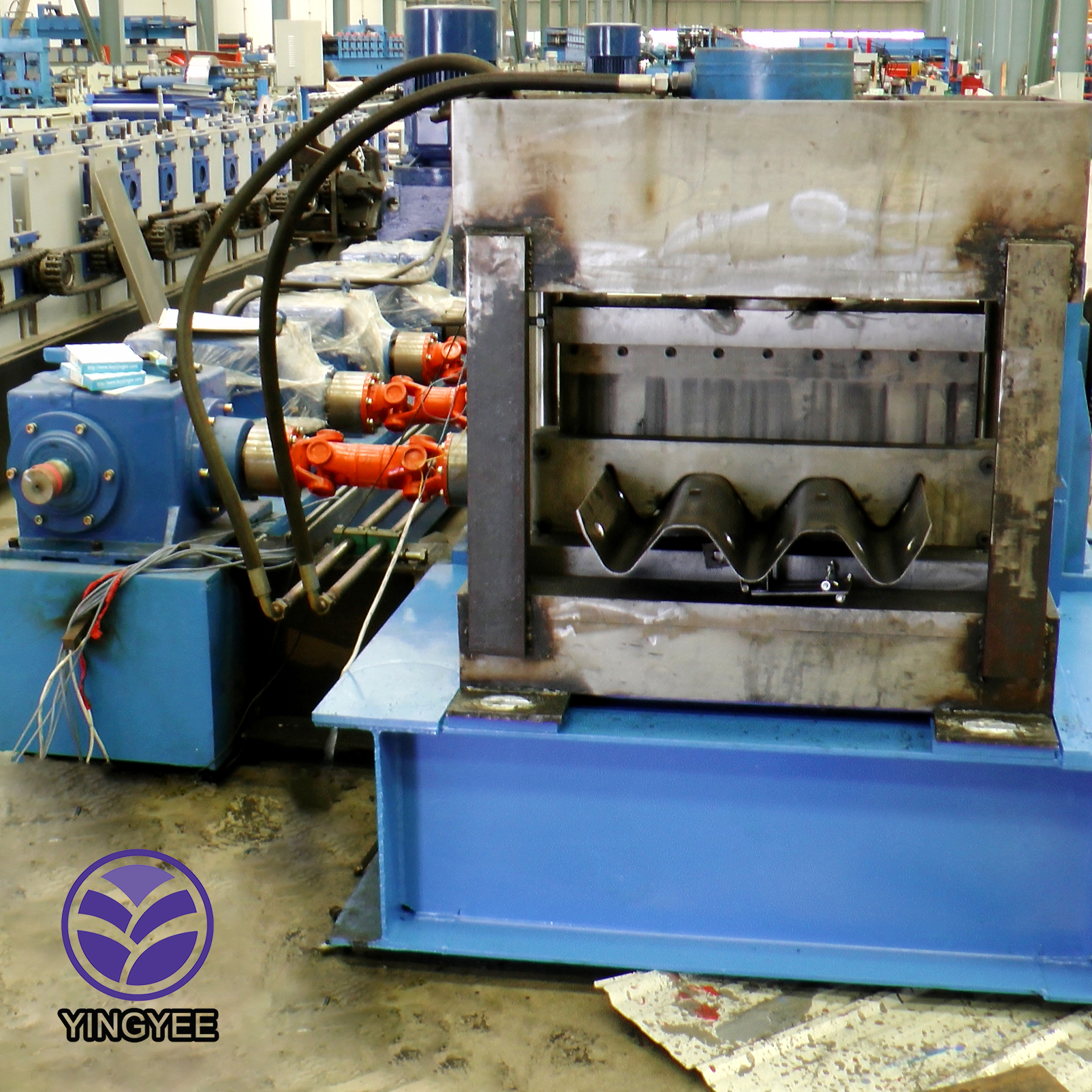

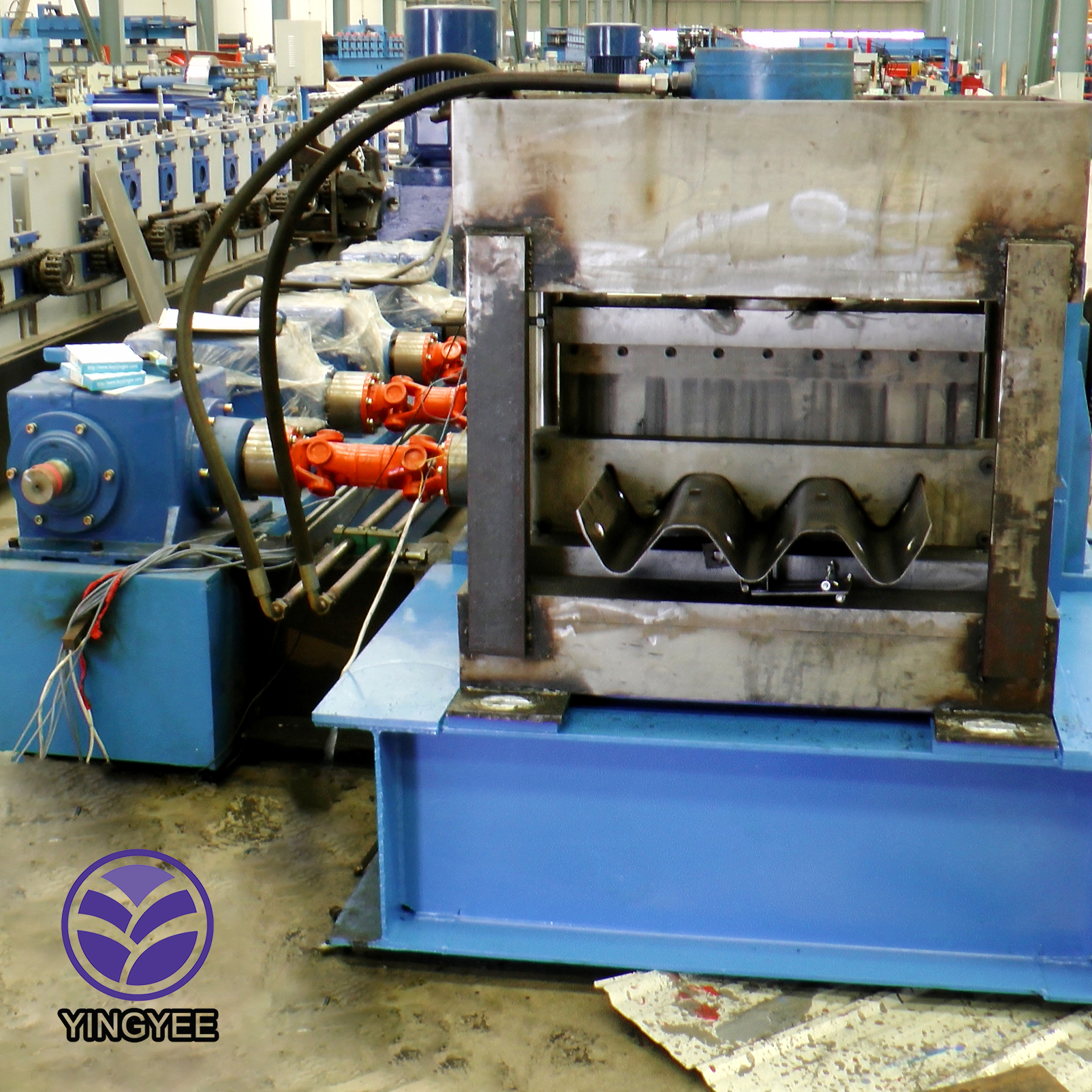

cable tray making machine

The reliability and credibility of a manufacturer are often reflected in the operational choices they make. By investing in high-quality machines and skilled personnel, a company signals its commitment to industry standards and customer satisfaction. High-end machines are designed by reputable brands that adhere strictly to global standards of safety and quality, thereby instilling confidence in clients and stakeholders alike. This trustworthiness extends to the final product, as customers are assured of the cable trays' compliance with both local and international safety regulations.

In the competitive landscape of cable tray production, having authoritative knowledge about your machinery can position a manufacturer as a leader in the industry. Keeping abreast of technological advancements and periodically upgrading machinery keeps production cutting-edge and elevates the manufacturer’s status as an innovator. Moreover, a documented history of successful projects using technologically advanced machinery enhances the company’s authority and credibility, paving the way for larger tenders and expanded market share.

To round off, investing in a cable tray making machine is a strategic decision rooted in enhancing quality and reliability. Expertise in its operation not only boosts efficiency but also fortifies the manufacturer’s reputation. Trust is built through consistent excellence, which stems from well-maintained equipment operated by knowledgeable staff. As technology progresses, staying informed and adaptable will remain crucial for those looking to excel in the realm of cable tray manufacturing. When this synergy between machinery and expertise is achieved, it translates into tangible business growth and sustained leadership in the market.