Straighten and Cutting Machine for Steel Coil

In the world of metal processing, the efficiency and precision of machines are paramount to ensure the highest quality products. Amongst these machines, the straightening and cutting machine for steel coils plays a critical role, especially in industries where steel is a fundamental material, such as automotive, construction, and manufacturing. This article explores the functionalities, benefits, and innovations surrounding straightening and cutting machines tailored for steel coils.

Functions of Straightening and Cutting Machines

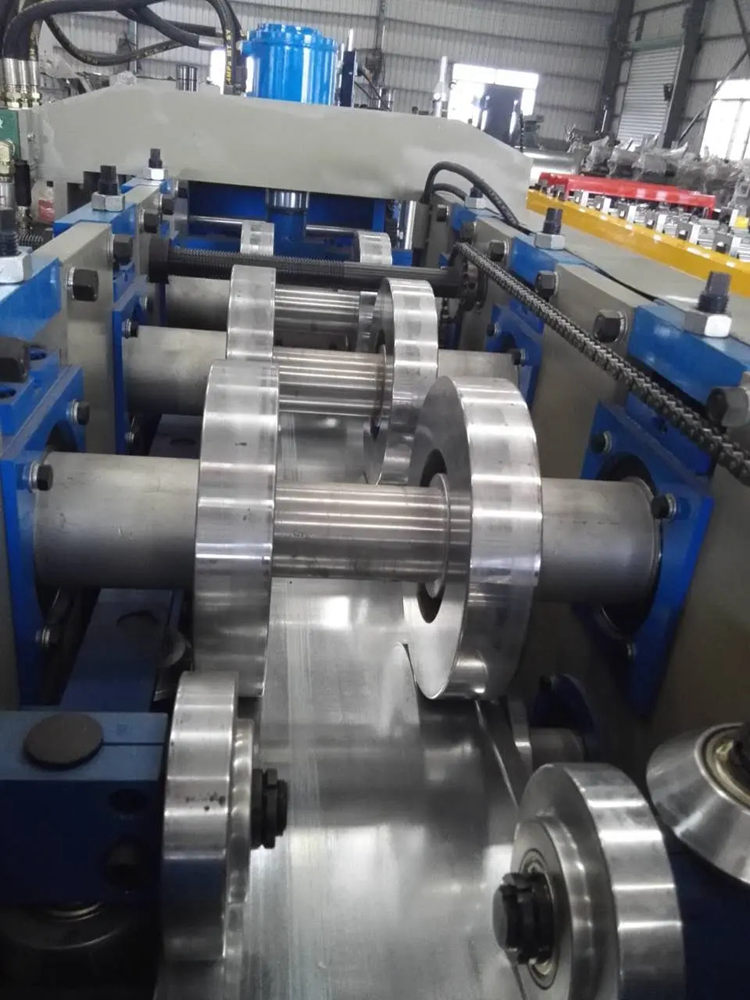

The primary function of a straightening and cutting machine is to transform coiled steel into flat sheets or strips that meet specific dimensional requirements. Steel coils, often received in a coiled format, can have undesirable characteristics such as curvature, bends, or twists. The straightening process rectifies these imperfections by applying a series of controlled forces, ensuring that the steel is uniformly flat.

Once straightened, the steel moves into the cutting phase, where precision cutting mechanisms are deployed. These machines can include standard shear cutting, rotary shear, or laser cutting options, depending on the required precision and thickness of the steel. The ability to program these machines for different lengths and widths means that manufacturers can reduce waste and increase efficiency, producing custom-sized pieces from a single coil.

Benefits of Using Straightening and Cutting Machines

The advantages of using straightening and cutting machines are multifold. Firstly, they significantly enhance productivity. By automating the straightening and cutting processes, manufacturers can achieve faster turnaround times, allowing for higher production volumes. This efficiency not only saves time but also reduces labor costs as fewer operators are needed to manage the machinery.

Secondly, the precision of these machines ensures that the products meet strict quality standards. In industries such as automotive manufacturing, where safety and reliability are critical, the ability to produce accurately dimensioned steel components is essential. Improperly straightened or cut steel can lead to manufacturing defects, which in turn can compromise the safety and effectiveness of the final product.

Moreover, modern straightening and cutting machines are designed with advanced technology that allows for better material handling. Features such as automatic coil loading, tension control systems, and high-speed cutting options enhance operational efficiency. Many machines now incorporate digital controls and sensors that monitor the straightening process in real time, making adjustments as needed to maintain accuracy.

Innovations in Straightening and Cutting Technology

As industries continue to evolve, so too do the technologies associated with steel processing. Innovations in straightening and cutting machines are moving towards greater automation and integration with Industry 4.0 standards. Machine learning algorithms and artificial intelligence are being employed to optimize performance and predict maintenance needs before issues arise.

Additionally, there is a growing emphasis on energy efficiency. Newer models of straightening and cutting machines are designed to consume less energy while improving performance. Manufacturers are increasingly focusing on eco-friendly practices, making machinery that minimizes waste and enhances sustainability.

In conclusion, straightening and cutting machines are indispensable in the steel processing industry. They not only improve the efficiency of production but also ensure the quality of the end products. With ongoing innovations in technology and a keen focus on automation and sustainability, the future of these machines looks promising. As they continue to evolve, they will play an even more significant role in meeting the demands of modern manufacturing while maintaining high standards of quality and efficiency.