In the modern landscape of infrastructure development, the AASHTO guardrail cold bending machine stands as a pivotal innovation in ensuring road safety and construction efficiency. This machinery is essential for creating guardrails that match the recommended standards set by the American Association of State Highway and Transportation Officials (AASHTO). Utilizing advanced technology, these machines provide precision, reliability, and consistency, ensuring that all safety specifications are met without compromise.

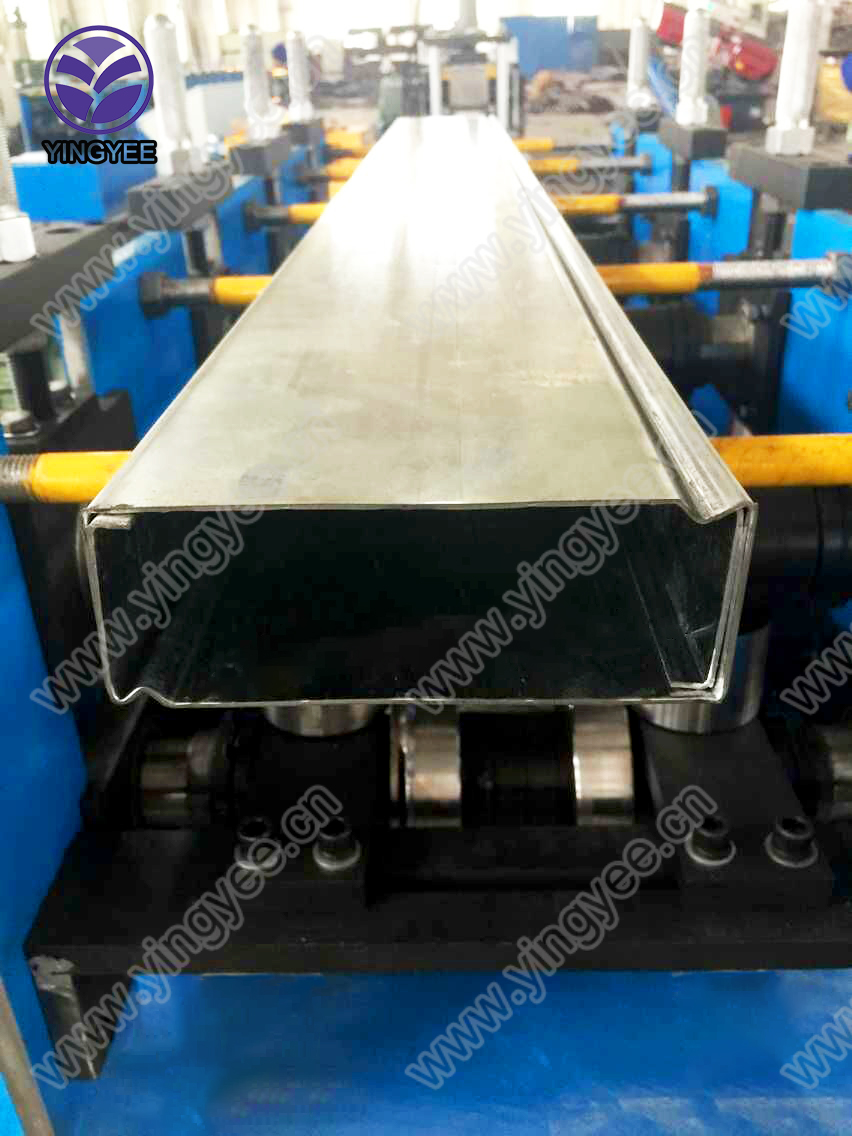

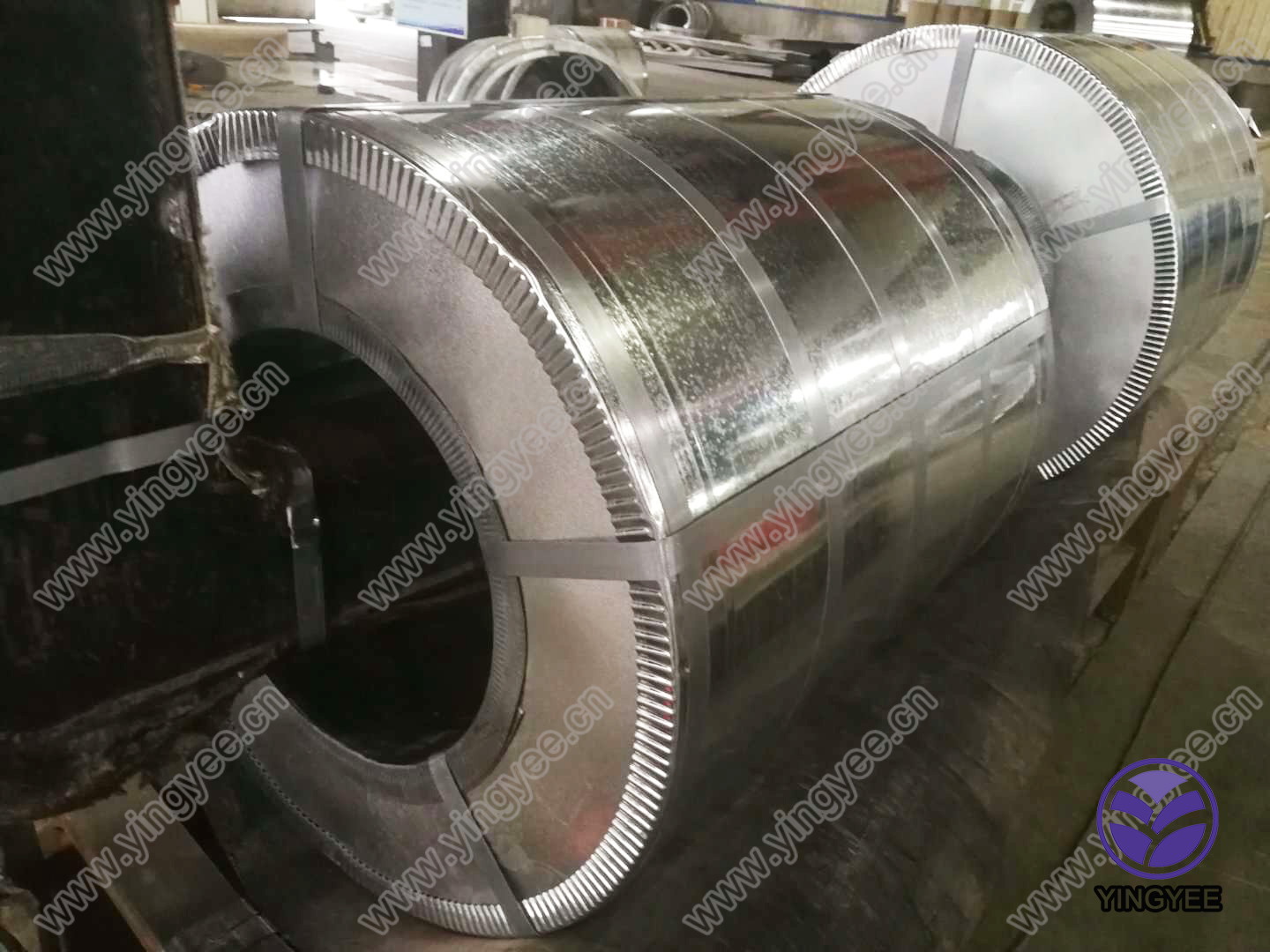

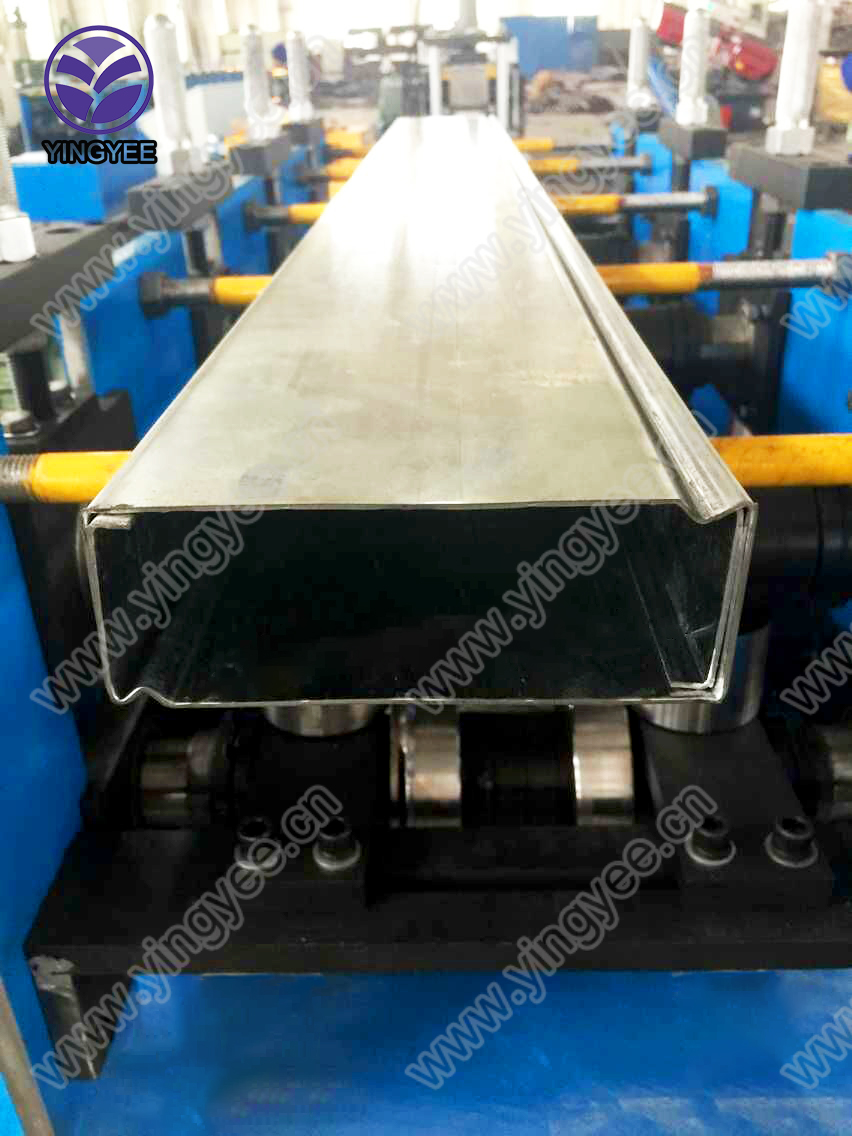

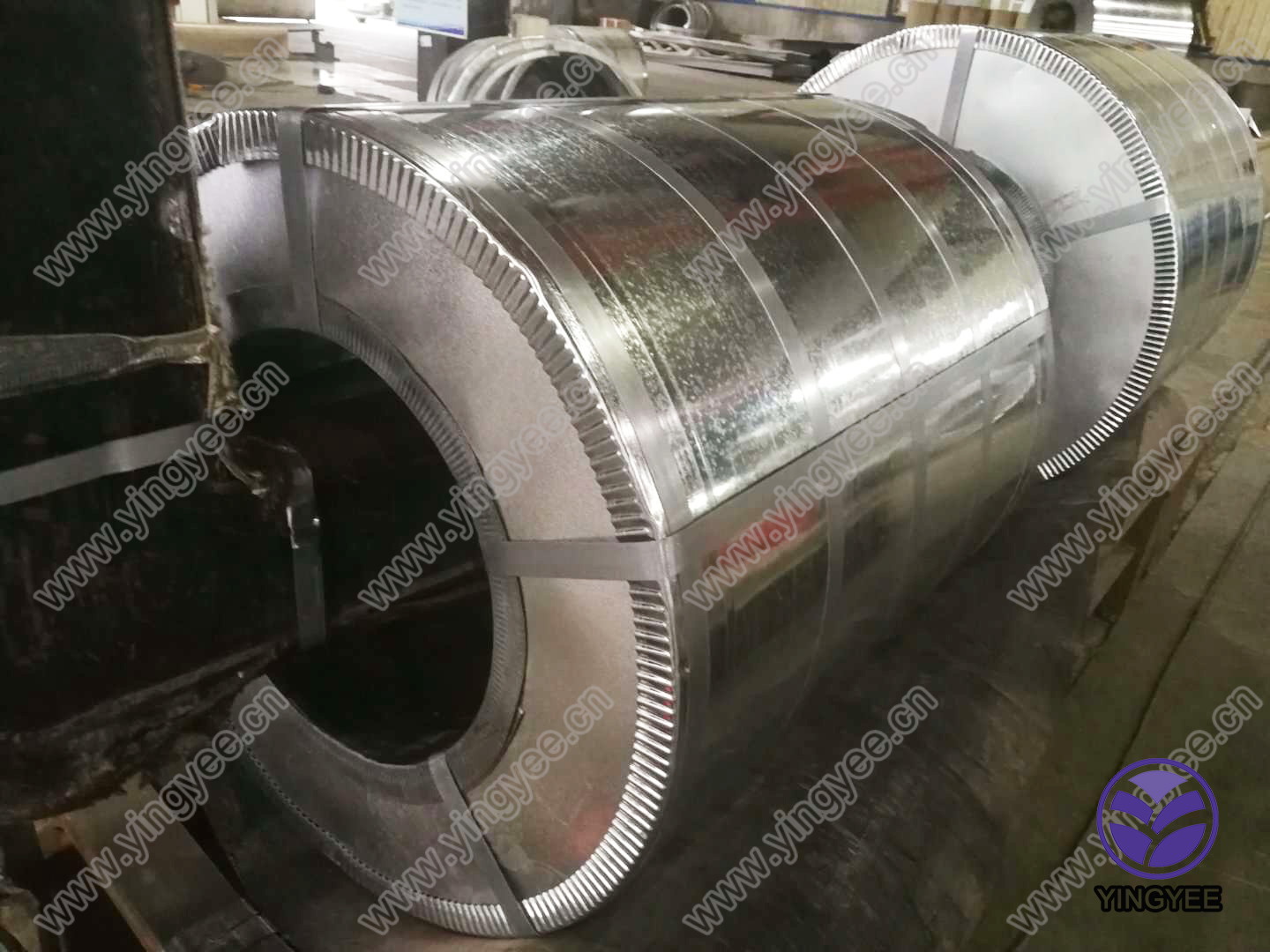

For engineers and construction professionals, the experience of operating an AASHTO guardrail cold bending machine is akin to working with a tool that not only meets industry standards but exceeds them. The cold bending process is remarkable for its ability to shape metal guardrails without the application of heat, preserving the material's structural integrity and ensuring longevity. This preservation is crucial in maintaining guardrail durability over time, particularly in harsh environmental conditions, thus boosting confidence in the safety of the installed systems.

From an expertise standpoint, the AASHTO guardrail cold bending machine requires a solid understanding of mechanical processes and precision engineering. Operators and technicians need to be proficient in handling the machine's features, such as its programmable settings and automated controls, which allow for the customization of bend angles and radii specific to project requirements. The level of specificity these machines can achieve is unparalleled, creating guardrails that perfectly fit the unique topography of different terrains.

Authoritativeness is cemented by the machine's widespread adoption in the industry, underlined by its design conformity with the rigorous AASHTO standards. The endorsement by such a reputable organization speaks volumes about the machine's credibility and its indispensable role in public safety. Manufacturers and suppliers of this machinery often employ experts who contribute to ongoing innovation and refinement, ensuring that the equipment remains cutting edge and authoritative within the industry.

aashto guardrail cold bending machine

Trustworthiness is further underscored by testimonials and case studies from numerous successful infrastructure projects where AASHTO guardrail cold bending machines have been utilized. The feedback from seasoned professionals highlights not only the machine's superior performance but also its reliability in high-stakes situations where precision and safety cannot be compromised. These accounts serve as compelling endorsements, showcasing the quality assurance and dependability of this essential tool.

As technology evolves, so does the AASHTO guardrail cold bending machine, incorporating the latest advancements to improve efficiency and reduce environmental impact. Modern machines are equipped with energy-saving mechanisms and adhere to eco-friendly practices, resonating with the industry’s shift towards sustainable development. This integration of green technology not only reduces operational costs but also minimizes the carbon footprint, aligning with global sustainability goals.

In conclusion,

the AASHTO guardrail cold bending machine is a quintessential example of engineering excellence and industrial innovation. It epitomizes the balance between expert craftsmanship, authoritative guidance, and trustworthy performance, making it a critical asset in the pursuit of safe and sustainable infrastructure development. Professionals in the field recognize it as an integral component of their toolkit, ensuring that every constructed guardrail stands as a testament to both human ingenuity and unwavering commitment to public safety.