Understanding Prepainted Galvanized Steel Coils A Comprehensive Overview

Prepainted galvanized steel coils have become a staple in various industries due to their versatility, durability, and aesthetic appeal. This article delves into the manufacturing process, applications, benefits, and considerations associated with prepainted galvanized steel coils, particularly in the range of 600-1500 mm.

What are Prepainted Galvanized Steel Coils?

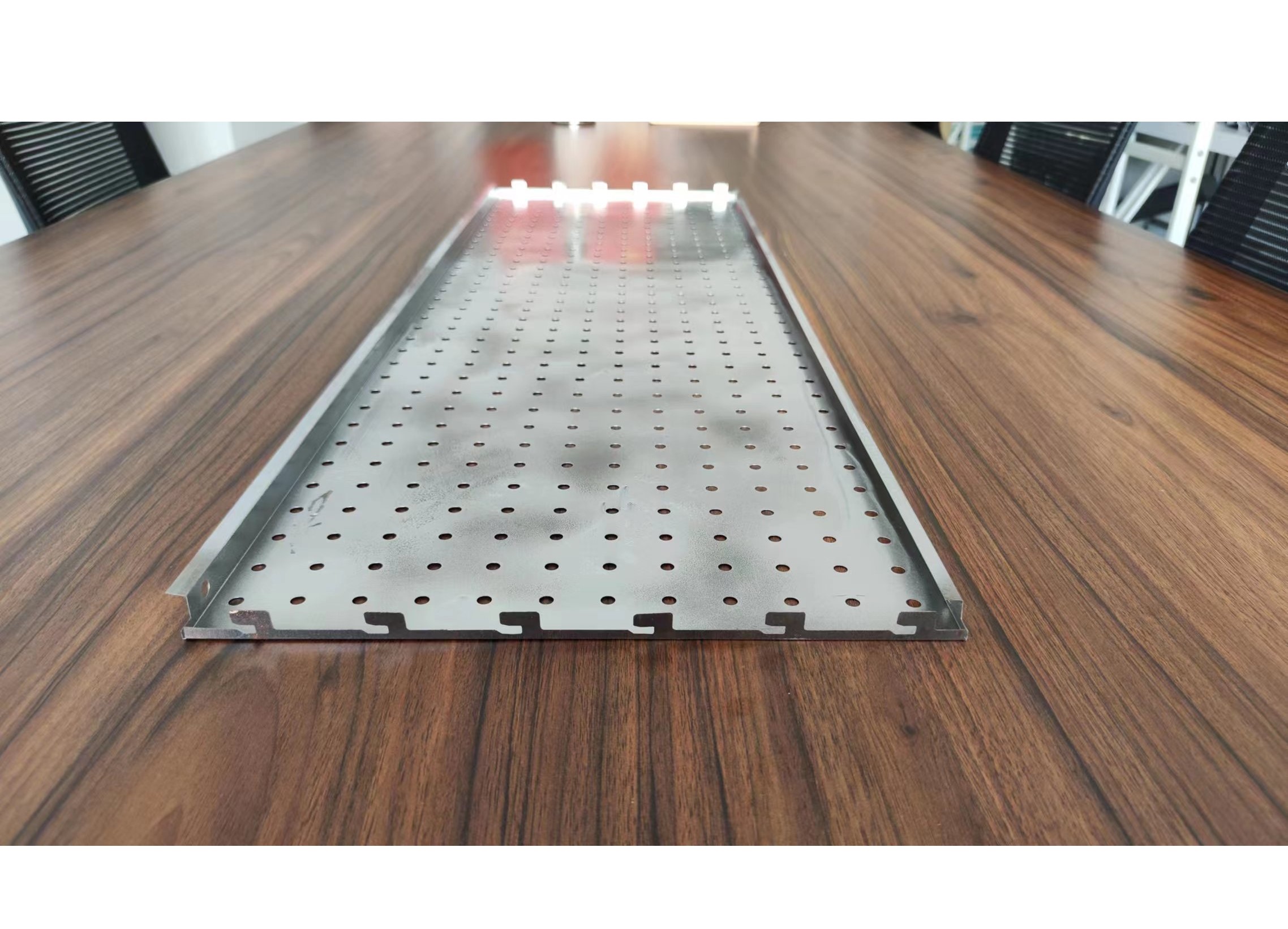

Prepainted galvanized steel coils are steel sheets that have been coated with a layer of zinc to prevent corrosion and then painted with a layer of protective paint. This dual-layer protection enhances the longevity of the steel while providing an attractive finish that can be customized to meet design requirements. The production of these coils involves the process of galvanization, which adds zinc to steel to create a protective barrier against rust. After galvanization, a primer and final paint layer are applied, leading to the product referred to as prepainted galvanized steel.

The Manufacturing Process

The development of prepainted galvanized steel coils starts with cold-rolled steel that is cleaned and annealed. Once prepared, the steel is submerged in molten zinc, a process known as hot-dip galvanization. The galvanized steel is then coated with a primer to promote paint adherence followed by painting. The final product is cured in an oven, where the paint hardens, ensuring it effectively bonds with the steel surface. The coils can then be stored or shipped for use in various applications.

Applications Across Industries

Prepainted galvanized steel coils are widely used in numerous industries due to their properties. Common applications include

1. Construction They are utilized for roofing, siding, and interior wall panels, providing not only structural integrity but also aesthetic appeal. 2. Automotive The automotive industry employs prepainted galvanized steel for various components, where durability and corrosion resistance are paramount.

3. Appliances Prepainted coils are prevalent in manufacturing household appliances, including refrigerators, washing machines, and ovens, where both performance and appearance matter.

4. Furniture They are also used in furniture manufacturing, offering unique designs in various colors and finishes.

5. Electrical Enclosures Due to their protective properties, these coils are fabricated into cabinets and enclosures for electrical components, safeguarding them from external elements.

Benefits of Prepainted Galvanized Steel Coils

1. Corrosion Resistance The zinc coating provides a robust barrier against rust and corrosion, ensuring the longevity of the steel in various environments.

2. Aesthetic Versatility With a wide range of colors and finishes available, prepainted galvanized steel can meet diverse aesthetic requirements, allowing for creativity in design.

3. Cost-Effectiveness The durability of these coils leads to reduced maintenance costs over time. Moreover, the need for fewer coatings in construction projects translates to lower overall material costs.

4. Ease of Fabrication The coils can be easily cut, formed, and welded, making them suitable for customized applications without compromising quality.

5. Sustainability Many manufacturers now focus on producing eco-friendly coatings and using recycled materials in their processes, contributing to environmental sustainability.

Considerations When Choosing Prepainted Galvanized Steel Coils

While the benefits are manifold, there are certain factors to consider when selecting prepainted galvanized steel coils. The environment in which the coils will be used plays a significant role, as exposure to harsh chemicals or conditions can impact their longevity. Additionally, the thickness of the steel, the quality of the paint, and the quality of the galvanization should be assessed to ensure the selected product meets the specific requirements of the application.

Conclusion

Prepainted galvanized steel coils ranging from 600-1500 mm represent an essential material choice across a multitude of industries. Their unique combination of durability, aesthetic flexibility, and cost-effectiveness makes them a suitable option for construction, automotive, appliances, and more. As industries continue to advance technologically, the demand for high-quality prepainted galvanized steel coils is expected to grow, driving innovations in manufacturing processes and applications. Understanding the intricacies of this material ensures informed decisions that promote both performance and design excellence.