Understanding Standing Seam Roof Machines An Essential Guide

In the world of modern architecture and construction, roofing plays a crucial role not only in protecting buildings but also in contributing to their aesthetic appeal. Among the various roofing systems available, the standing seam roof stands out for its durability, efficiency, and modern design. To achieve these benefits, specialized equipment known as standing seam roof machines is employed. In this article, we will explore what standing seam roofs are, the benefits they offer, and the role of standing seam roof machines in the roofing industry.

What is a Standing Seam Roof?

A standing seam roof is a type of metal roofing system characterized by vertical panels that rise above the level of the roof deck, creating distinct seams between each panel. These seams are standing in that they are elevated, allowing for effective water drainage and reducing the risk of leaks. Typically constructed from materials such as aluminum, copper, or galvanized steel, standing seam roofs are particularly popular in commercial and residential buildings for their longevity and low maintenance requirements.

Benefits of Standing Seam Roofs

1. Durability Standing seam roofs are incredibly resilient. They are designed to withstand harsh weather conditions, including heavy rain, snow, and strong winds. Metal roofing is fire-resistant, making it a safer choice for both commercial and residential buildings.

2. Energy Efficiency One of the significant advantages of standing seam roofs is their energy efficiency. Many metal roofing materials are reflective, meaning they can help keep buildings cooler in hot weather. Some manufacturers even offer insulated panels that can enhance energy savings by regulating indoor temperatures.

3. Aesthetic Appeal Standing seam roofs provide a sleek, modern look that can enhance the overall architectural style of a building. Available in various colors and finishes, these roofs can complement a wide range of design preferences.

4. Maintenance These roofs require minimal maintenance compared to traditional roofing systems. Their design prevents the accumulation of debris, and the absence of exposed fasteners eliminates potential leak points.

5. Environmentally Friendly Most standing seam roof panels are made from recyclable materials, making them an eco-friendly option for buildings. Furthermore, their longevity reduces the need for frequent replacements, contributing to waste reduction.

The Role of Standing Seam Roof Machines

Manufacturing standing seam roofs involves specialized machinery designed to create the panels and seam structures efficiently. Standing seam roof machines automate the production process, ensuring that panels are consistent in quality and precise in measurement. These machines come in various configurations, tailored for different production needs, including portable options for job sites or larger machines for factory settings.

Key Functions of Standing Seam Roof Machines

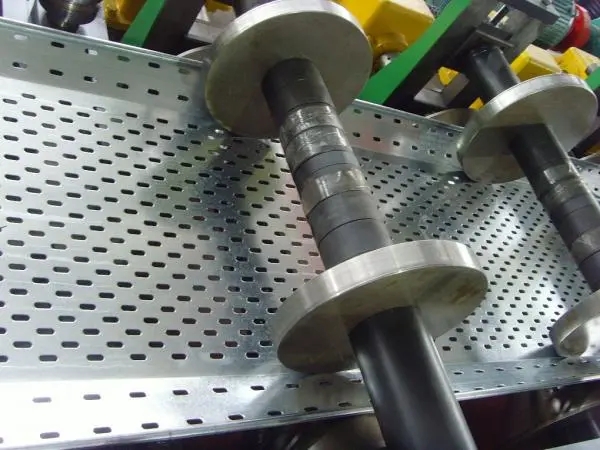

1. Metal Forming The primary function of these machines is to form metal sheets into the specific shape required for standing seam panels. They utilize rolls and dies to create the standing seams and other profiles needed for installation.

2. Cutting Standing seam roof machines often come equipped with cutting tools that allow for precise lengths tailored to the building's specifications. This capability is essential for ensuring there is minimal waste during installation.

3. Coiling Many machines can handle coiled metal, which is more efficient for shipping and handling. This feature allows contractors to work directly from coils, reducing the need for handling large sheets and making the installation process smoother.

4. Seaming After the panels have been formed and cut, the machines can also seam the panels together, providing a tight, secure fit that is crucial for preventing leaks and maintaining the roof's integrity.

5. Customization Advanced standing seam roof machines offer flexibility, enabling manufacturers to customize panel lengths, widths, and seam styles. This customization allows builders to meet specific architectural requirements and preferences.

Conclusion

Standing seam roofs represent a significant advancement in roofing technology, providing unmatched durability and aesthetic flexibility. The specialized standing seam roof machines play an integral role in this evolution, streamlining the manufacturing process and ensuring high-quality, customizable products. As the construction industry continues to evolve, the adoption of such advanced technologies will undoubtedly enhance the efficiency and effectiveness of roofing solutions, making standing seam roofs an increasingly popular choice for builders and homeowners alike.